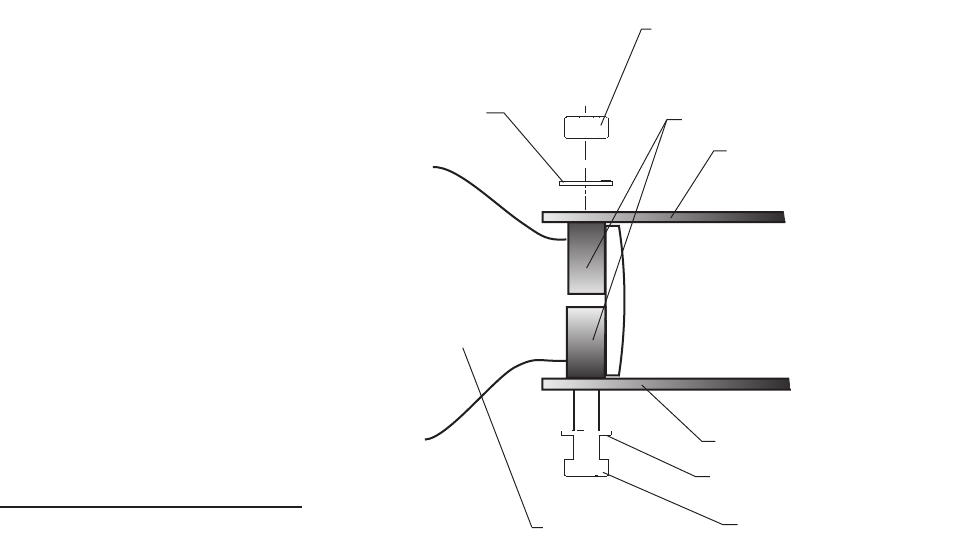

5

2–Remove one set of blade clamps from the hub assembly. Blade

clamps are installed on the hub assembly at the factory with spacers

for shipping purposes. Remove and discard the spacers. Position

the blade clamps around the shank of a blade with the machined-

face end of the blade clamp against the blade safety shoulder. See

Figure 5. Large nylon cable ties can be used to hold blade clamps

on the blade during installation providing easier assembly.

3–Insert the blade with blade clamps around the shank and with

the concave blade side (TOP) on the discharge side between

the hub assembly plates as shown in Figure 4. Vertically align

the two bolt holes in the clamps and plates. Install two lubricated

C\v″ bolts, four C\v″ at washers, (two C\v″ lock washers if hardware ma-

terial is monel), and two C\v″ hex nuts, engaging the nuts only three

to four threads as shown in Figure 5. Do not tighten the hardware

until all the blades have been installed. The blade must be free to

rotate in the clamp for pitch adjustment.

4–Repeat until all blades, clamps, and hardware have been installed

in the hub assembly.

BLADE CLAMP

FLAT WASHER

MACHINE BOLT

FAN BLADE

HUB PLATE

HUB PLATE

FLAT WASHER

LOCKING HEX NUT OR

HEX NUT AND LOCK WASHER

Figure 5