SpectraPure

SpectraPure®Inc.

480.894.5437 Call us toll-free 1.800.685.2783

2167 East Fifth St, Tempe, Arizona 85281

®

6

METERING AND DIAGNOSITCS

This SpectraPure purification system has been fully equipped with sufficient instrumentation

to make monitoring and troubleshooting an easy process. The provided pressure gauge is

used to determine the tap water pressure and to evaluate the condition of the sediment

and carbon prefilters.

(The pressure will drop as the pre-filters become clogged by dirt [turbidity] from the tap

water).

The digital TDS meter (left side) will provide a reliable means of evaluating the efficiency of

the RO membrane. This meter will indicate the tap water conductivity and the RO water

conductivity. The difference between the two meter readings will be used to calculate the

percentage of rejection of the (TFC) RO membrane.

The Digital TDS meter (right side) will be used to determine the condition of the two stages

of the DI system. As the reading on the meter begin to increase, the operator will be alerted

to the possibility that the DI system may have deteriorated past the exhaustion point and

that the DI cartridges may need to be replaced.

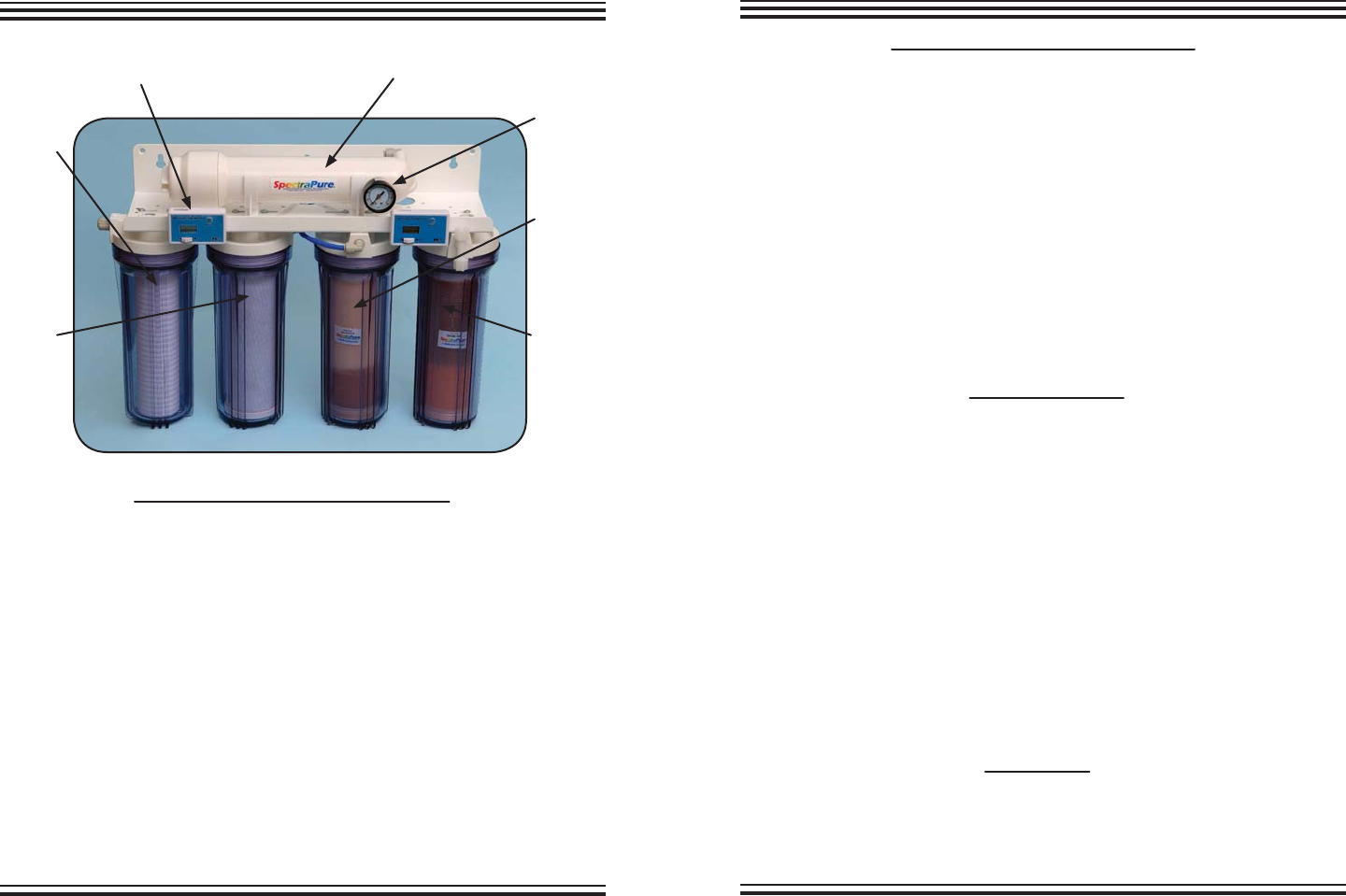

Fig. A: System Components

TFC RO Membrane

(MEM-150)

.5 micron

MicroTec™

Sediment

Pre-Filter

(SF-MT-.5-

10)

.5 micron

Carbon

Block Pre-

Filter (CF-.5-

10)

Pressure

Guage

(2) TDS

Monitors

DI

Cartridge #1

DI-MC-10

DI

Cartridge #2

DI-SB-10

SpectraPure®Inc

. Fax 480.894.6109 Fax us toll-free 1.877.527.7873

E-mail: spectra@spectrapure.com Visit us on the web www.spectrapure.com

19

SpectraPure

®

USING THE PRESSURE GAUGE

The pressure gauge is used to monitor the condition of the Sediment and Carbon

Pre-Filters. With the Sediment and Carbon filters removed, the gauge will indicate

the “actual” input water tap water pressure. When the prefilters are “new”, the

pressure shown on the gauge will be slightly less than the actual tap water

pressure and as the filters age the pressure will drop due to the dirt that will

collect in the prefilters. When the pressure on the gauge drops below 40-PSI or as

the filters collect particulates and the pressure drop is greater than 15% to 20% of

the normal water pressure, the pre-filters are in need of replacement.

NOTE: When the pressure on the pressure gauge drops below the normal

readings; do not “assume” that the sediment filter is the only cause. In some

geographical areas where the input water contains a high percentage of very

small micron particulates, the carbon filter may become clogged before the

sediment filter. (The filters may look “new” but still cause the water pressure to

drop). Do not judge the condition of the prefilters by their color, always use the

pressure gauge to determine the condition of the prefilters.

MAINTENANCE

The maintenance and trouble-shooting procedures have been made easy and

effective with a combination of the Pressure gauge and two dual Inline TDS

meters.

- When there is a pressure drop of 15% of your normal house

pressure that is an indication that your pre-filters need to be

replaced.

- The TDS monitors will let you know when the TDS level rises. All

our membranes have a 98% rejection. When the TDS level starts

to rise the % rejection will decrease. You should replace the

membrane before the % rejection gets to 90%.

It is highly recommended that one set of Sediment and Carbon

replacement filters should be on hand and ready for installation as soon as the

fist monitor indicates that a cartridge change or replacement is required. We do

not recommend that you have a replacement

membrane and DI because they do have a shelf life.

STORAGE

1. It is recommended that you store your RO System in a cool place

when not being used.

2. Your RO System must be protected from freezing or temperatures

above 100° F (38°C).