Page 15

SERIES 28A BOILER INSTALLATION AND OPERATION INSTRUCTIONS

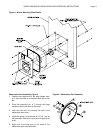

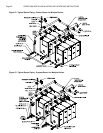

Figure 15 - Relief & Safely Valve Piping

WATER BOILER PIPING

The supply and return connections should be sized

to suit the system, see Figures 13, 14, 16, 17 and Tables

5 & 6. Do not pipe the supply from the bottom port or

the return to the top port, the boiler will not work

properly. Typical water boiler piping arrangements are

shown in Figures 18 & 19. Swing joints should be used.

Install 3" nipples into the two 3" NPT tappings in the

front section and cap them.

NOTE: See CLEANING OF WATER BOILERS on page

18 before proceeding!

Supply Piping

Install a reducing bushing in the 6" NPT tapping in the

front section to obtain the correct supply pipe size,

Figure 13 and Tables 5 & 6.

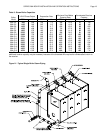

Table 6 - Water Boiler Piping

Boiler Size Return Size Supply Size

# Sections NPT NPT

4 & 5 3 3

6 through 9 4 4

10 through 18 5 5

Note: Sizes based on 20°F, 11.1°C, ∆T for the system.

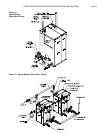

Return Piping 4 Through 9 Section Boilers

Install 3" x 4" NPT bushings in the two 4" NPT tappings

at the bottom of the back section. Install the two 3" NPT

x 6" nipples per Figure 16. Assemble the rest of the

return yoke as shown in Figure 16.

Table 7 - Boiler Water Content

Boiler Model Water Boilers Steam Boilers

Gallons

Liters

Gallons

Liters

28A-4 123

466

104

394

28A-5 150

568

126

477

28A-6 177

670

148

560

28A-7 204

772

170

644

28A-8 231

875

192

727

28A-9 258

977

214

810

28A-10 285

1079

236

893

28A-11 312

1181

258

977

28A-12 339

1283

280

1060

28A-13 366

1386

302

1143

28A-14 392

1484

324

1227

28A-15 419

1586

346

1310

28A-16 446

1689

368

1393

28A-17 473

1791

399

1511

28A-18 500

1893

412

1560

Return Piping 10 Through 18 Section Boilers

Install the two 4" NPT x 6" nipples per Figure 16.

Assemble the rest of the return yoke as shown in Figure

16.

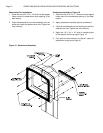

Control Installation

Locate the temperature & pressure gage, low water

cutoff, high limit and operating controls per Figures 13

& 7. Optional controls must be installed in accordance

with the control manufacturers instructions and Figures

13 & 17.

NOTE: The front jacket panel MUST be installed

before any controls are attached to the front boiler

section!

CAUTION: The controls must be mounted in the

correct location and according to the control

manufacturer’s instructions or the boiler may not

function properly!

Water Column Piping

A variety of water level controls are available for the 28A.

The water column piping needed to properly mount each

control is available from Smith. Figure 17 shows a typical

water column piping arrangement. The 1" NPT x 7 1/2"

nipple is always installed in the lower water column

tapping, Figures 13 & 17 and Table 5.