Computer-aided design. Highest quality manufacturing.

Superior components.

Advanced design S-Series heat exchanger

provides superior performance, longer life.

Computer-aided design of the SE boiler’s heat exchanger

maximizes transfer of heat from the gas flame to the boiler water

which then flows into your heating system. Superior heat transfer

properties permit use of smaller, compact cast-iron heat exchanger

sections. The flue passage design, thermal pin pattern and consis-

tent wall thickness ensure uniform heat transfer with less thermal

strain and metal fatigue.

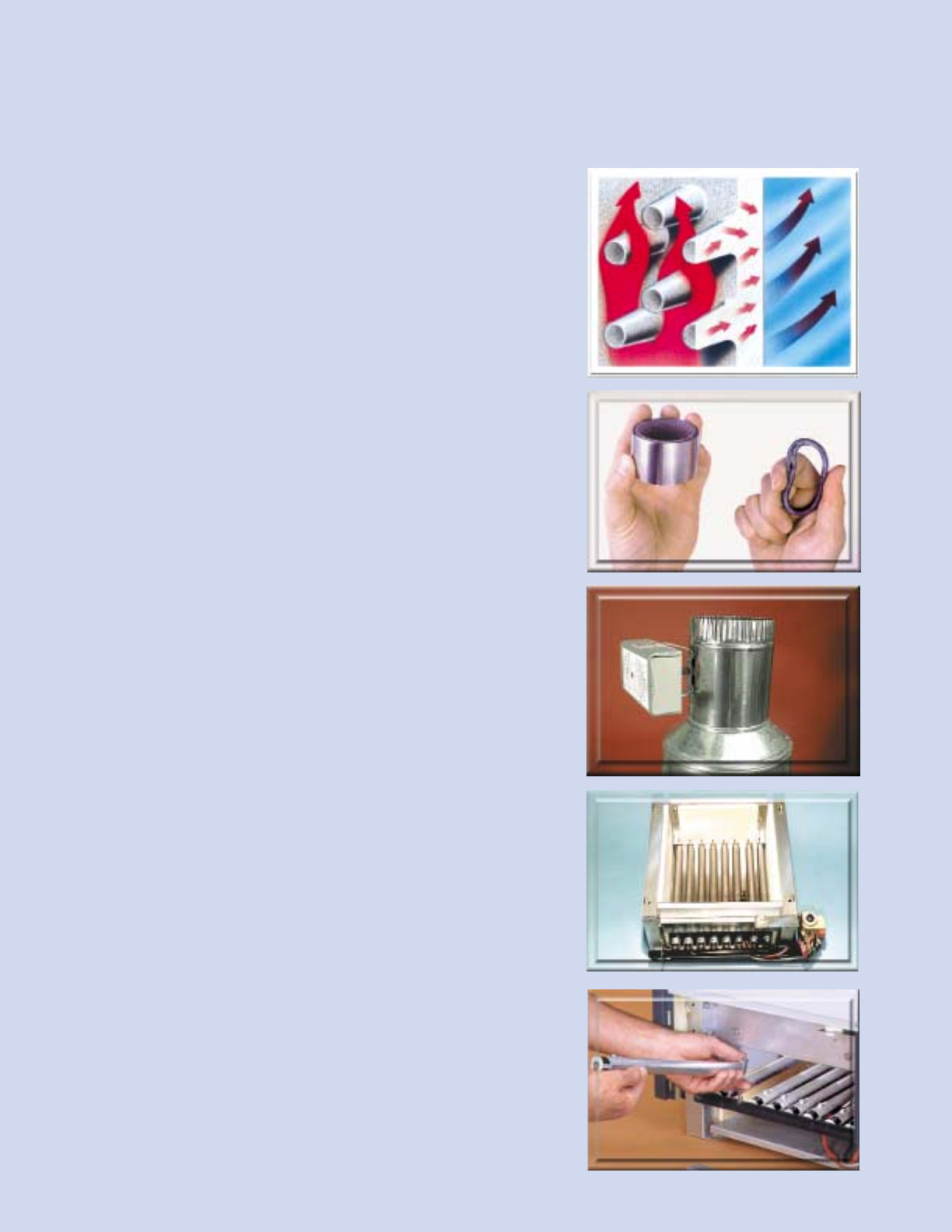

Metal push nipples avoid leaks.

Slant/Fin uses only metal push nipples that expand and contract

with the individual boiler sections that they connect. In many

ordinary boilers, flimsy rubber or plastic gaskets are substituted for

metal push nipples and are subject to deterioration and leaks.

Reliable heavy-duty vent damper saves energy.

The motorized Slant/Fin vent damper increases efficiency of the

boiler by reducing standby losses. Motor closes the chimney vent

when the burner is off, fully opens it in anticipation of combustion.

May be installed horizontally or vertically to accommodate varying

vent pipe requirements. Support collar maintains dimensional

stability for smooth operation.

Long-life burners

Quiet, light and easy to install or remove. Same stainless steel

burners serve natural or propane gas. Special port construction

will not permit flame to “lift” or flash back. Burners last longer

too, because of low operating temperature. Input per burner is

17,500 Btu/hr.

Insulated base

Base is constructed of heavy gauge aluminized steel. Thick

refractory insulation surrounds combustion chamber, minimizing

standby losses and increasing efficiency.