(7) If equipped with vent damper, which can ONLY be

installed on boilers equipped with 24 volt gas valve:

(a) Your vent damper must be OPEN when the boiler is

operating (BURNERS ARE ON). Ask your installer

or serviceperson to show you the vent damper posi-

tion indicator, indicating the open and closed

damper positions. Inspect for proper operation

monthly. If damper position indicator indicates that

the damper is closed when the boiler is operating,

SHUTDOWN the boiler immediately and call your

service agency.

(b) This device must be installed and inspected annually

by a qualified installer in accordance with the

Slant/Fin vent damper installation instructions. If

improperly installed, a hazardous condition such as

explosion or carbon monoxide poisoning could

result. If installed improperly, all vent damper and

boiler warranties shall be voided.

SERVICE INSPECTION

The selected service organization should make these

inspections, pref

erably once each year, before the cold

weather begins:

(1) Make the checks for leaks, corrosion, noise, flame,

heat and outside air supply described under User’s

Inspection.

(2) Check safety operation of the HIGH LIMIT CON-

TR

OL (and, for steam boilers, the LOW WATER

CUT

OFF) and GAS VALVE. If the boiler is equipped

with an automatic vent damper, check this device for

saf

e and automatic operation.

(3) Check gas input rate, by clocking the gas meter.

Inspect burner flame. Clean and adjust burners and

adjust gas rate as required.

(4)

Disconnect flue pipe from draft hood. Remove draft

hood and inspect boiler heating surface below. If any

soot, scale or rust is visible, clean the boiler as

described in the next section.

(5) Replace any corroded smokepipe. Repair or re-

place other devices as found necessary. Check and

adjust for normal operation. Explain to the user

what was done and what to look for to prevent fu-

ture problems.

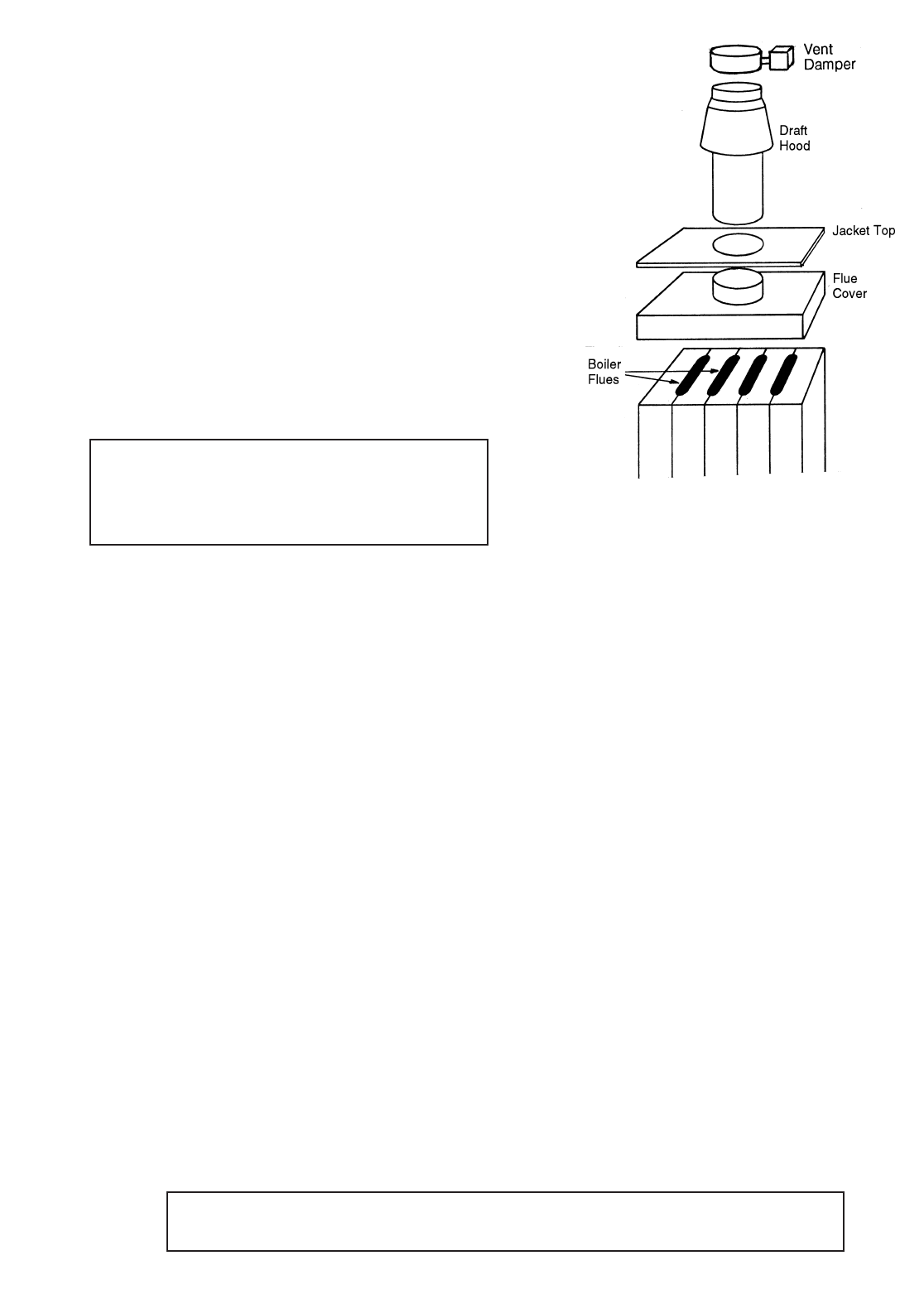

CLEANING—BOILER, SMOKEPIPE,

CHIMNEY

(See Figure 21). If necessary as indicated

in (4) of Service Inspection section, the selected service

organization should clean the boiler as follows:

(1) Shut off electric power and gas supply.

(2) Disconnect smokepipe and remove draft hood.

(3) Remove jacket top panel. Remove flue cover

from boiler.

(4) Remove access door and remove burners, or place

cover over burners for dirt protection.

(5) Brush down boiler flues to bare metal. Clean all

debris from bottom of boiler after brushing.

Clean b

urner slots, if necessary.

(6) Replace flue cover and seal with furnace cement.

Replace burners if removed. Replace access door.

(7) Inspect draft hood and smokepipe. If corroded,

replace. If soot or deposits from condensation are

found, clean out, and inspect inside of chimney for

soot or other deposits. Clean if necessary.

(8) Reconnect hood and flue pipe and fasten and seal

all joints. Turn on gas and electric power.

(9) Check boiler performance after cleaning, and adjust

as necessary.

NOTE: Condensate (water), rust, scale and soot are not

found in the boiler or smokepipe of normally operating

system. If any of these is found, eliminate the cause.

The most likely cause of condensate and corrosion or

soot is (a) restr

icted air supply, or (b) a faulty chimney.

Your gas boiler must be installed and serviced by a qualified service agency or

gas supplier. The lack of proper service can result in a dangerous condition.

If you find during your inspection any unusual

noise, water leak, corroded smokepipe, abnor-

mal water pressure or flame rollout, call for

service immediately.

6

Figure 21.