Troubleshooting

Operation 4

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

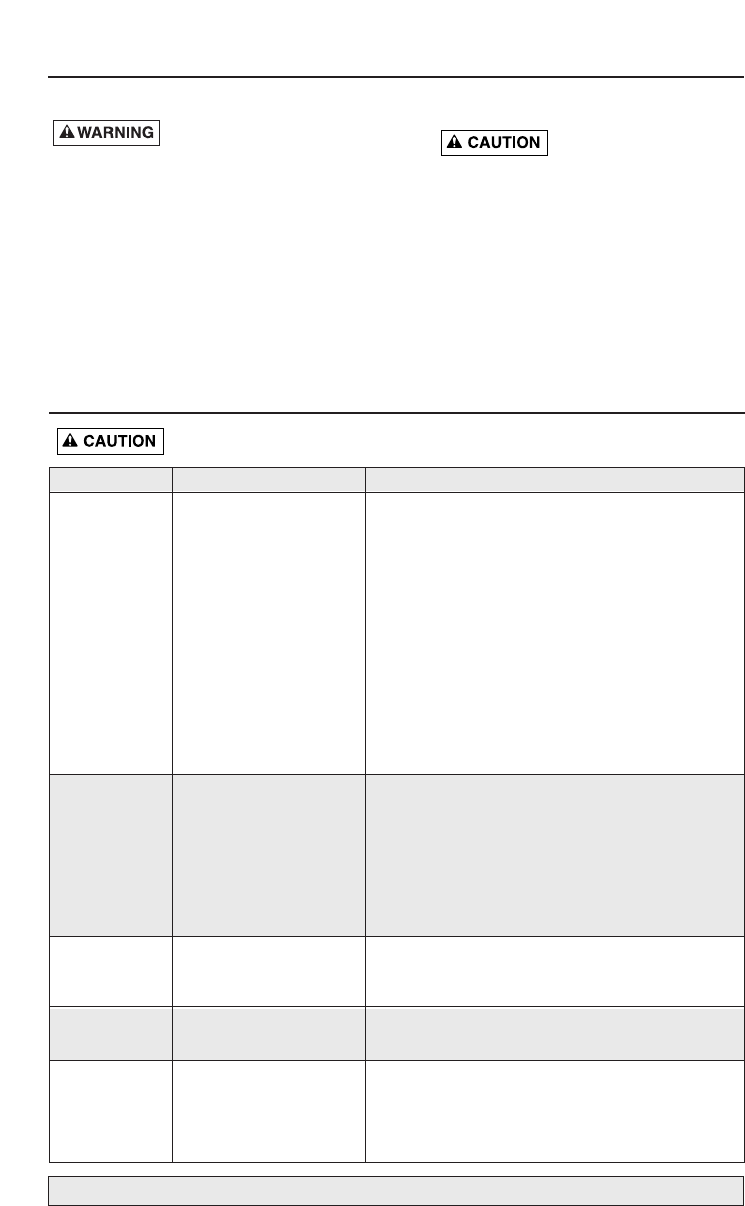

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Motor will not No electrical power Check fuse, circuit breaker, power cord and

startor run electrical outlet.

Low line voltage If voltage wiring under recommended minimum,

check size of wiring from main source. If OK,

contact Electric Company or local Hydro authority.

Faulty automatic switch Operate switch manually and replace if inoperative.

Float or float rod stuck Check to see float is not rubbing sump wall or float

rod rubbing or stuck against sump cover.

Waterlogged float Replace float if filled with water.

Motor overload tripped If pump has been running and stops before sump

is emptied, automatic overload may have tripped.

Check inlet screen to be sure impeller is not

jammed. If so, free impeller of obstruction.

Electrical malfunction Check power cord, automatic switch and motor.

Replace faulty parts as needed.

Motor runs but Inlet clogged Check inlet and clean if needed.

pump will not Discharge line plugged Clear discharge line and check valve for

pump obstruction.

Low line voltage Refer to Corrective Action on low line voltage in

above section.

Pump airlocked Drill a 1/8" (3.2mm) hole in discharge pipe just

above pump body but below the check valve.

Broken impeller or shaft Replace impeller or shaft as needed.

Pump starts and Improper positioning of Lower float rod stop.

stops too often float rod stop

Faulty automatic switch Replace automatic switch.

Pump is noisy Improper installation Refer to No. 5 in Installation Instructions.

Noisy motor Replace pump.

Pump will not Debris around float or Remove debris from sump. Check to see float is

stop running float rod stuck not rubbing sump wall or float rod rubbing or stuck

against sump cover.

Faulty automatic switch Replace switch.

Motor defective Replace pump.

Unplug pump from power receptacle before working on pump.

OPERATION

Do not touch sump pump, pump

motor, water, or discharge piping

when pump is connected to electrical power. Always

disconnect pump cord (power) before handling.

1. Plug this unit into a 115V outlet, on an individ-

ual branch circuit, with a Class A, 15 amp

GFCI (Ground Fault Circuit Interrupter).

Consult your local electrician for information

and availability.

2. Fill sump pit with water, pump will start auto-

matically when lower rod stop actuates switch

lever arm. When upper rod stop actuates

switch lever arm, pump will stop.

NOTICE: Do not allow pump to run dry.

Before attempting to service,

always disconnect power

from unit.

3. The motor is equipped with an automatic reset

thermal protector to protect unit from overheat-

ing. When motor has cooled sufficiently, switch

will reset automatically and restart motor.

Repeated tripping could be caused by low volt-

age, long extension cords, clogged impeller,

very low head or lift, etc. Cycling of protector

will cause eventual motor burnout.