For assistance,call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Troubleshooting 5

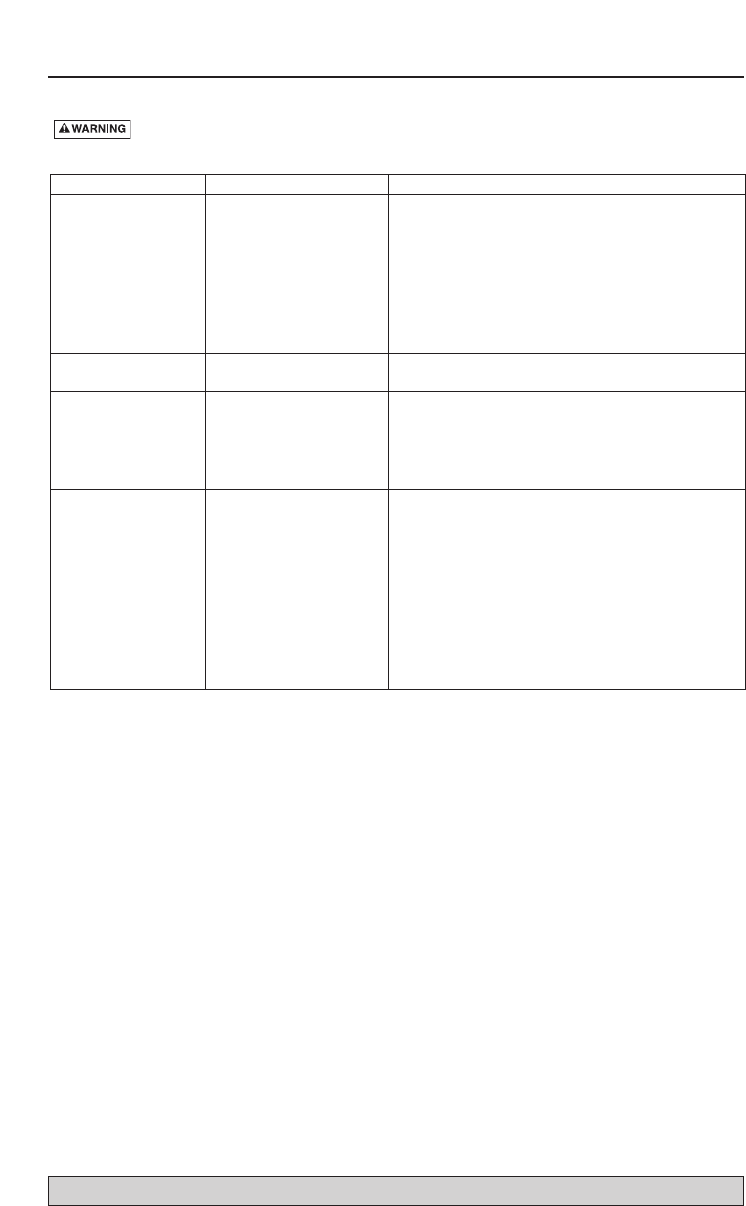

SYMPTOM PROBABLE CAUSE(S) CORRECTIVE ACTION

Pump won’t start or run. Pump is not plugged in. Check and see if pump is plugged in to a proper outlet.

Blown fuse. If blown, replace with fuse of proper size.

Low line voltage. If voltage under recommended minimum, check size of wiring

from main switch on property. If OK, contact power company

or hydro authority.

Defective motor. Replace pump.

Defective float switch. Replace float switch.

Impeller. If impeller won’t turn, remove lower pump body and locate

source of binding.

Float obstructed. Remove obstruction.

Pump starts and stops Backflow of water from piping. Install or replace check-valve.

too often.

Faulty float switch. Replace float switch.

Pump won’t shut off. Defective float switch. Replace float switch.

Restricted discharge Remove pump and clean pump and piping.

(obstacle or ice in piping).

Float obstructed. Remove obstruction.

Restricted intake screen. Remove the pump and clean the intake screen and the

impeller.

Pump operates but Low line voltage. If voltage under recommended minimum, check size of wiring

delivers little or no water. from main switch on property. If OK, contact power company

or hydro authority.

Something caught in impeller. Remove the pump and clean out the impeller.

Worn or defective parts or Clean impeller if plugged;otherwise replace pump.

plugged impeller.

Check valve installed without Drill a 1/16" - 1/8" (1.6mm - 3.2mm) dia. hole between pump

vent hole. discharge & check valve (1-2” above where the discharge

pipe screws into the pump discharge and below the

waterline).

Restricted intake screen. Remove the pump and clean out the intake screen.

Check valve is installed either Be sure check valve is installed correctly.

backward or upside down.

TROUBLESHOOTING CHART

Hazardous voltage and risk of electric shock. Can shock, burn, or kill. Unplug pump before

servicing or cleaning pump.