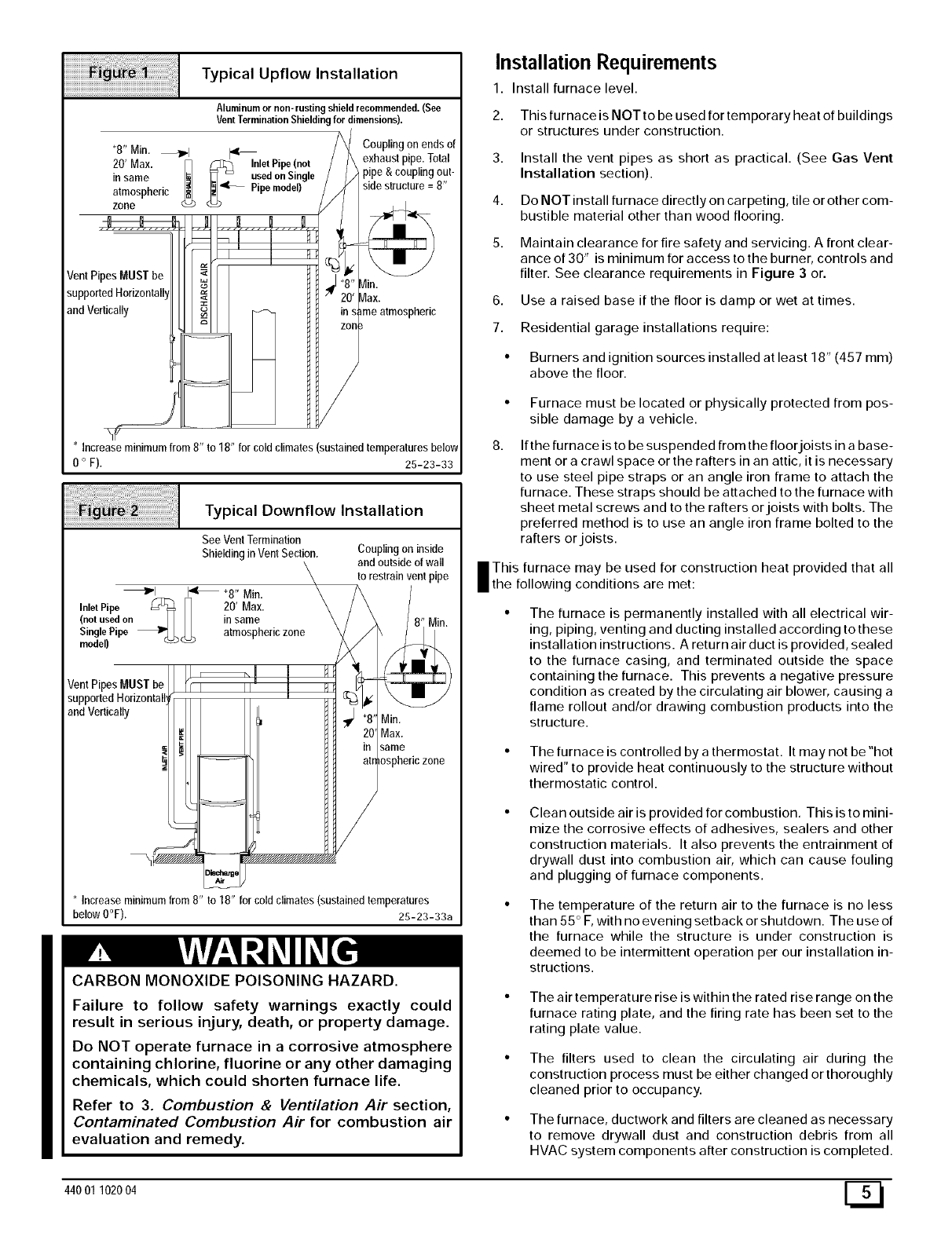

Typical Upflow Installation

Aluminumornon-rustingshield recommended.(See

VentTerminationShieldingfor dimensions).

Coupling on ends of

*8" Min. _l[q _I_ exhaust pipe. Total

20' Max. Inlet Pipe(not

insame _ _ usedon Single pipe & coupling out-

atmospheric <_ __4t_ Pipemodel) side structure =8"

zone

VentPipesMUSTbe

/]in.

supported

andVertically meatmospheric

* Increase minimum from 8" to 18" for cold climates (sustained temperatures below

0 ° F). 25-23-33

Typical Downflow Installation

SeeVentTermination

Shieldingin VentSection.

_1 14' *8" Min.

InletPipe _ [_ 20' Max.

(not usedon _ _ in same

SinglePipe _ I,,,_L, atmospheric zone

model) _

VentPip MUSTbq

support( 4orizonta

andVertically

Coupling on inside

and outside of wall

to restrain vent pipe

Min.

Max.

same

osphericzone

* Increase minimum from 8" to 18" for cold climates (sustained temperatures

below O°F). 25-23-33a

CARBON MONOXIDE POISONING HAZARD.

Failure to follow safety warnings exactly could

result in serious injury, death, or property damage.

Do NOT operate furnace in a corrosive atmosphere

containing chlorine, fluorine or any other damaging

chemicals, which could shorten furnace life.

Refer to 3. Combustion & Ventilation Air section,

Contaminated Combustion Air for combustion air

evaluation and remedy.

Installation Requirements

1. Install furnace level.

2. This furnace is NOT to be used for temporary heat of buildings

or structures under construction.

3. Install the vent pipes as short as practical. (See Gas Vent

Installation section).

4. Do NOT install furnace directly on carpeting, tile or other com-

bustible material other than wood flooring.

5. Maintain clearance for fire safety and servicing. A front clear-

ance of 30" is minimum for access to the burner, controls and

filter. See clearance requirements in Figure 3 or.

6. Use a raised base if the floor is damp or wet at times.

7. Residential garage installations require:

• Burners and ignition sources installed at least 18" (457 ram)

above the floor.

8.

Furnace must be located or physically protected from pos-

sible damage by a vehicle.

If the furnace is to be suspended from the floorjoists in a base-

ment or a crawl space or the rafters in an attic, it is necessary

to use steel pipe straps or an angle iron frame to attach the

furnace. These straps should be attached to the furnace with

sheet metal screws and to the rafters or joists with bolts. The

preferred method is to use an angle iron frame bolted to the

rafters or joists.

I his furnace may be used for construction heat provided that all

the following conditions are met:

The furnace is permanently installed with all electrical wir-

ing, piping, venting and ducting installed according to these

installation instructions. A return air duct is provided, sealed

to the furnace casing, and terminated outside the space

containing the furnace. This prevents a negative pressure

condition as created by the circulating air blower, causing a

flame rollout and/or drawing combustion products into the

structure.

• The furnace is controlled by a thermostat. It may not be "hot

wired" to provide heat continuously to the structure without

thermostatic control.

Clean outside air is provided for combustion. This is to mini-

mize the corrosive effects of adhesives, sealers and other

construction materials. It also prevents the entrainment of

drywall dust into combustion air, which can cause fouling

and plugging of furnace components.

The temperature of the return air to the furnace is no less

than 55 ° F,with no evening setback or shutdown. The use of

the furnace while the structure is under construction is

deemed to be intermittent operation per our installation in-

structions.

• The air temperature rise iswithin the rated rise range on the

furnace rating plate, and the firing rate has been set to the

rating plate value.

• The filters used to clean the circulating air during the

construction process must be either changed or thoroughly

cleaned prior to occupancy.

• The furnace, ductwork and filters are cleaned as necessary

to remove drywall dust and construction debris from all

HVAC system components after construction is completed.

44001 102004 [_