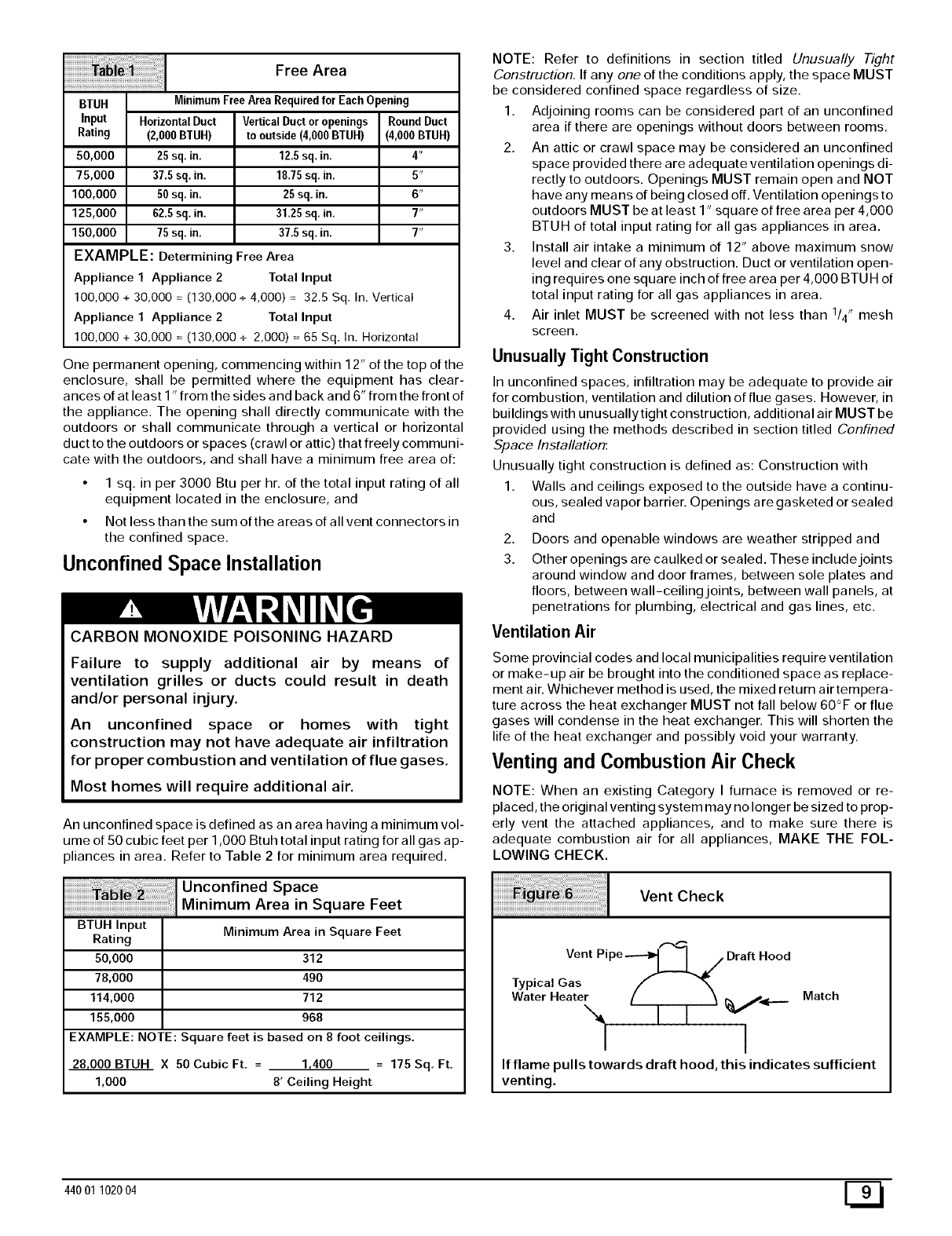

Free Area

BTUH MinimumFreeAreaRequiredforEach Opening

Input HorizontalDuct VerticalDuctoropenings RoundDuct

Rating (2,000BTUH) to outside(4,000BTUH) (4,000BTUH)

50,000 25 sq. in. 12.5sq.in. 4"

75,000 37.5sq.in. 1825 sq. in. 5"

100,000 50sq.in. 25sq. in. 6"

125,000 62.5sq.in. 3125 sq. in. 7"

150,000 75 sq. in. 37.5sq.in. 7"

EXAMPLE: Determining Free Area

Appliance 1 Appliance 2 Total Input

100,000 + 30,000 = (130,000 + 4,000) = 32.5 Sq. In. Vertical

Appliance 1 Appliance 2 Total Input

100,000 + 30,000 = (130,000 + 2,000) = 65 Sq. In. Horizontal

One permanent opening, commencing within 12" of the top of the

enclosure, shall be permitted where the equipment has clear-

ances of at least 1" from the sides and back and 6" from the front of

the appliance. The opening shall directly communicate with the

outdoors or shall communicate through a vertical or horizontal

duct to the outdoors or spaces (crawl or attic) that freely communi-

cate with the outdoors, and shall have a minimum free area of:

• 1 sq. in per 3000 Btu per hr. of the total input rating of all

equipment located in the enclosure, and

• Not less than the sum ofthe areas of all vent connectors in

the confined space.

Unconfined Space Installation

CARBON MONOXIDE POISONING HAZARD

Failure to supply additional air by means of

ventilation grilles or ducts could result in death

and/or personal injury.

An unconfined space or homes with tight

construction may not have adequate air infiltration

for proper combustion and ventilation of flue gases.

Most homes will require additional air.

BTUH Input

Rating

50,000

78,000

114,000

155,000

An unconfined space is defined as an area having a minimum vol-

ume of 50 cubic feet per 1,000 Btuh total input rating for all gas ap-

pliances in area. Refer to Table 2 for minimum area required.

I Unconfined Space

Minimum Area in Square Feet

Minimum Area in Square Feet

312

49O

712

968

EXAMPLE: NOTE: Square feet is based on 8 foot ceilings.

28,000 BTUH X 50 Cubic Ft. = 1,400 = 175 Sq. Ft.

1,000 8' Ceiling Height

NOTE: Refer to definitions in section titled Unusually Tight

Construction, If any one of the conditions apply, the space MUST

be considered confined space regardless of size.

1. Adjoining rooms can be considered part of an unconfined

area if there are openings without doors between rooms.

2. An attic or crawl space may be considered an unconfined

space provided there are adequate ventilation openings di-

rectly to outdoors. Openings MUST remain open and NOT

have any means of being closed off. Ventilation openings to

outdoors MUST be at least 1" square of free area per 4,000

BTUH of total input rating for all gas appliances in area.

3. Install air intake a minimum of 12" above maximum snow

level and clear of any obstruction. Duct or ventilation open-

ing requires one square inch of free area per 4,000 BTU H of

total input rating for all gas appliances in area.

4. Air inlet MUST be screened with not less than 1/4" mesh

screen.

Unusually Tight Construction

In unconfined spaces, infiltration may be adequate to provide air

for combustion, ventilation and dilution of flue gases. However, in

buildings with unusually tight construction, additional air MUST be

provided using the methods described in section titled Confined

Space Installation:

Unusually tight construction is defined as: Construction with

1. Walls and ceilings exposed to the outside have a continu-

ous, sealed vapor barrier. Openings are gasketed or sealed

and

2,

3.

Doors and openable windows are weather stripped and

Other openings are caulked or sealed. These includejoints

around window and door frames, between sole plates and

floors, between wall-ceiling joints, between wall panels, at

penetrations for plumbing, electrical and gas lines, etc.

Ventilation Air

Some provincial codes and local municipalities require ventilation

or make-up air be brought into the conditioned space as replace-

ment air. Whichever method is used, the mixed return air tempera-

ture across the heat exchanger MUST not fall below 60°F or flue

gases will condense in the heat exchanger. This will shorten the

life of the heat exchanger and possibly void your warranty.

Venting and Combustion Air Check

NOTE: When an existing Category I furnace is removed or re-

placed, the original venting system may no longer be sized to prop-

erly vent the attached appliances, and to make sure there is

adequate combustion air for all appliances, MAKE THE FOL-

LOWING CHECK.

Vent Check

Vent Pipe----_,l I 7 Draft Hood

Typical Gas f _'_

WaterHeate / i i Match

I I

If flame pulls towards draft hood, this indicates sufficient

venting.

44001 102004 [_