3. Newlabelsforrightside-upapplicationonoutsideofblower

compartmentdoormaybepurchasedinakitfromyourdistrib-

utortocoverupside-downlabels.

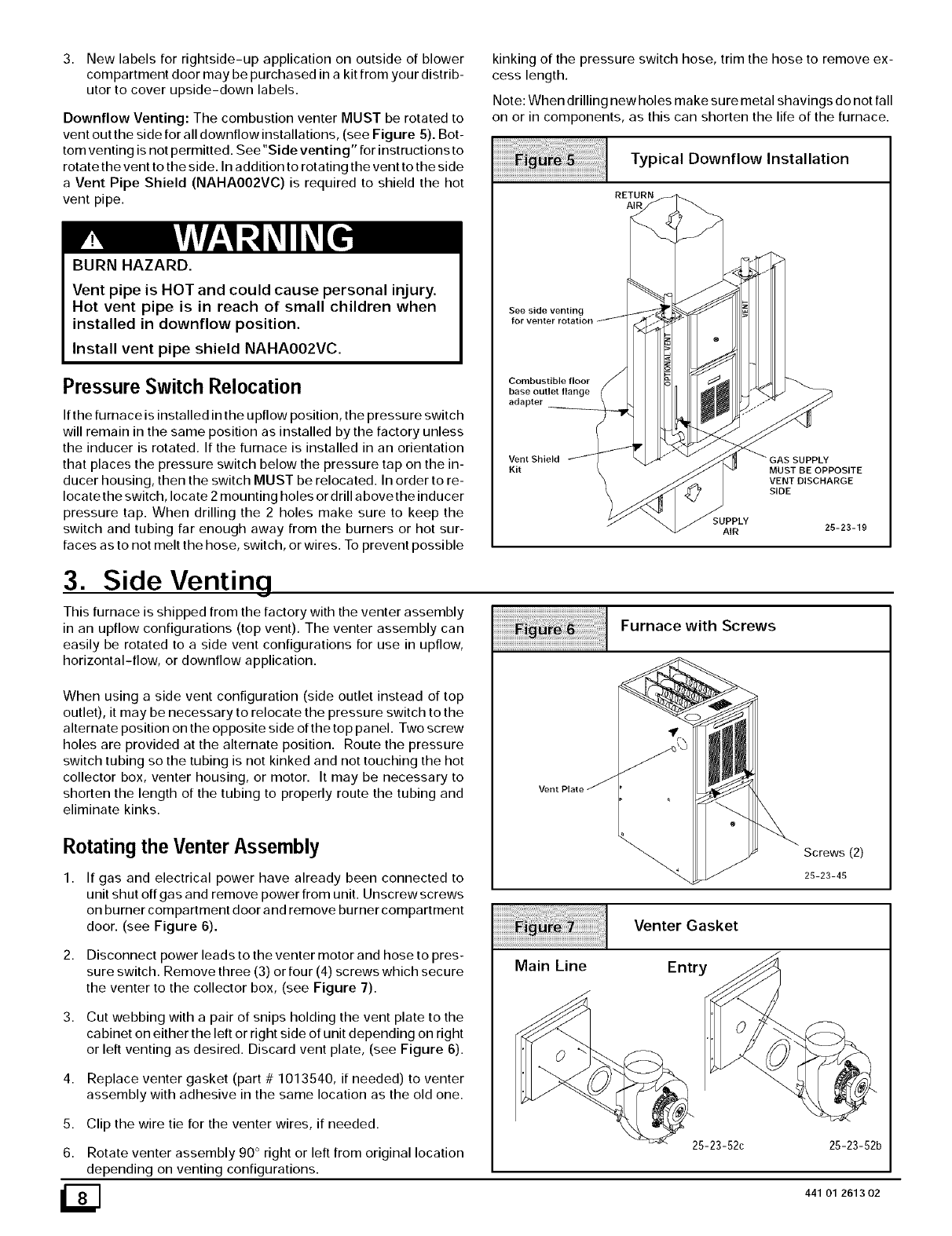

DownflowVenting:ThecombustionventerMUSTberotatedto

ventoutthesideforalldownflowinstallations,(seeFigure5).Bot-

tomventingisnotpermitted.See"Sideventing"forinstructionsto

rotatetheventtotheside.Inadditiontorotatingtheventtotheside

aVentPipeShield(NAHAOO2VC)isrequiredtoshieldthehot

ventpipe.

BURN HAZARD.

Vent pipe is HOT and could cause personal injury.

Hot vent pipe is in reach of small children when

installed in downflow position.

Install vent pipe shield NAHA002VC.

Pressure Switch Relocation

If the furnace is installed in the upflow position, the pressure switch

will remain in the same position as installed by the factory unless

the inducer is rotated. If the furnace is installed in an orientation

that places the pressure switch below the pressure tap on the in-

ducer housing, then the switch MUST be relocated. In order to re-

locate the switch, locate 2 mounting holes or drill above the inducer

pressure tap. When drilling the 2 holes make sure to keep the

switch and tubing far enough away from the burners or hot sur-

faces as to not melt the hose, switch, or wires. To prevent possible

3. Side Venting

This furnace is shipped from the factory with the venter assembly

in an upflow configurations (top vent). The venter assembly can

easily be rotated to a side vent configurations for use in upflow,

horizontal-flow, or downflow application.

When using a side vent configuration (side outlet instead of top

outlet), it may be necessary to relocate the pressure switch to the

alternate position on the opposite side of the top panel. Two screw

holes are provided at the alternate position. Route the pressure

switch tubing so the tubing is not kinked and not touching the hot

collector box, venter housing, or motor. It may be necessary to

shorten the length of the tubing to properly route the tubing and

eliminate kinks.

Rotating the Venter Assembly

1,

2,

3,

4,

5.

6.

If gas and electrical power have already been connected to

unit shut off gas and remove power from unit. Unscrew screws

on burner compartment door and remove burner compartment

door. (see Figure 6).

Disconnect power leads to the venter motor and hose to pres-

sure switch. Remove three (3) or four (4) screws which secure

the venter to the collector box, (see Figure 7).

Cut webbing with a pair of snips holding the vent plate to the

cabinet on either the left or right side of unit depending on right

or left venting as desired. Discard vent plate, (see Figure 6).

Replace venter gasket (part # 1013540, if needed) to venter

assembly with adhesive in the same location as the old one.

Clip the wire tie for the venter wires, if needed.

Rotate venter assembly 90 ° right or left from original location

depending on venting configurations.

kinking of the pressure switch hose, trim the hose to remove ex-

cess length.

Note: When drilling new holes make sure metal shavings do not fall

on or in components, as this can shorten the life of the furnace.

Typical Downflow Installation

RETURN

AIR

See side venting

Combustible floor

base outlet flange

adapter

Vent Shield

Kit MUST BE OPPOSITE

VENT DISCHARGE

SIDE

SUPPLY

AIR 25-23-19

Furnace with Screws

Venter Gasket

Main Line Entry

Screws (2)

25-23-45

25-23-52c 25-23-52b

441 01 2613 02