IINSTALLATION

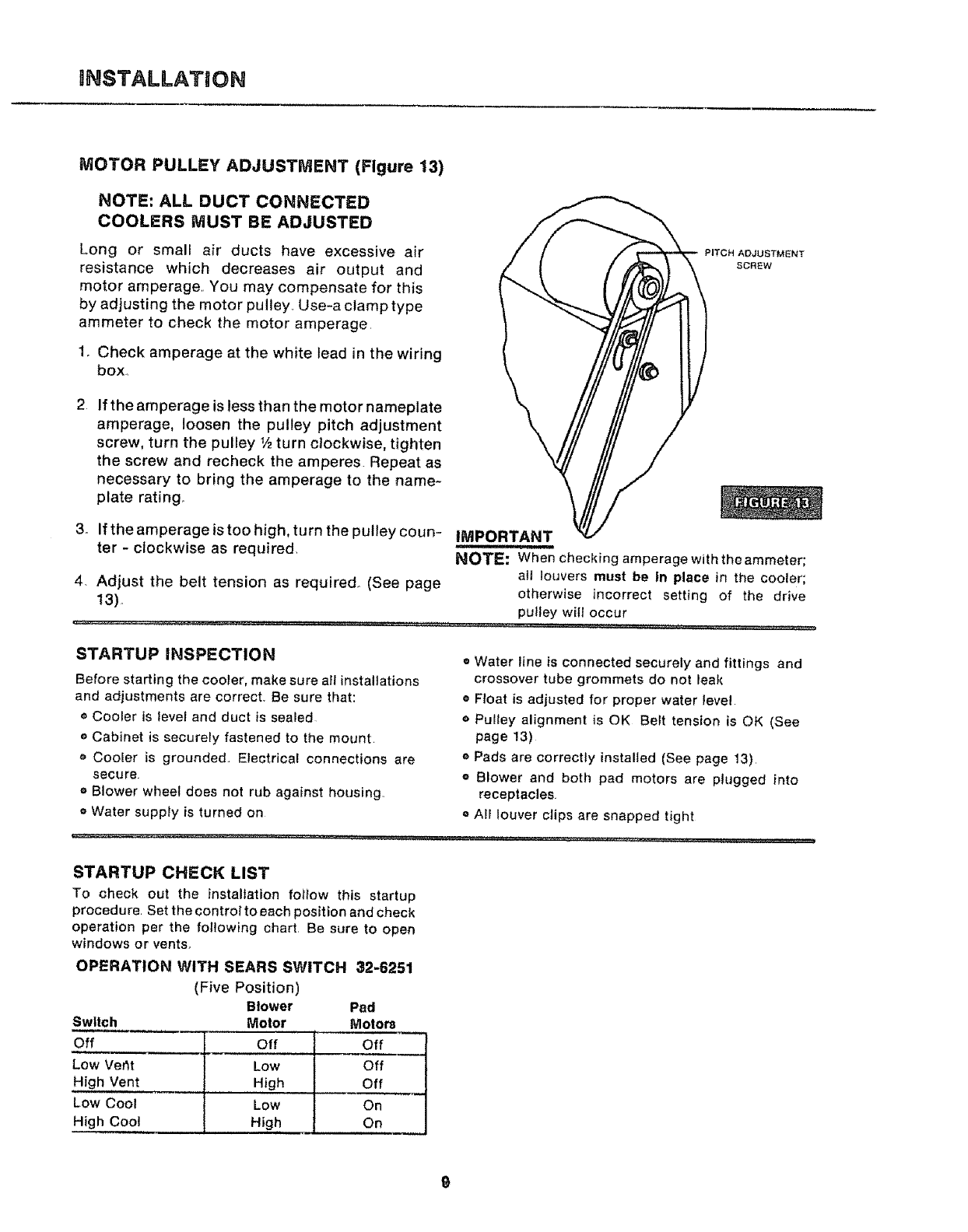

MOTOR PULLEY ADJUSTMENT (Figure 13)

NOTE: ALL DUCT CONNECTED

COOLERS MUST BE ADJUSTED

Long or small air ducts have excessive air

resistance which decreases air output and

motor amperage, You may compensate for this

by adjusting the motor pulley. Use-a clamptype

ammeter to check the motor amperage

1o Check amperage at the white lead in the wiring

box,,

PITCH ADJUSTMENT

SCREW

2 If the amperage is less than the motor nameplate

amperage, loosen the pulley pitch adjustment

screw, turn the pulley _ turn clockwise, tighten

the screw and recheck the amperes Repeat as

necessary to bring the amperage to the name-

plate rating°

3. If the amperage is too high, turn the pulley coun- IMPORTANT

ter - clockwise as required. NOTE: When checking amperage with theammeter;

all louvers must be tn place in the cooler;

4 Adjust the belt tension as required (See page

13). otherwise incorrect setting of the drive

pulley will occur

STARTUP INSPECTION

Before starting the cooler, make sure al! installations

and adjustments are correct. Be sure that:

Cooler is level and duct is sealed

e Cabinet is securely fastened to the mount

o Cooler is grounded Electrical connections are

secure

o Blower wheel does not rub against housing.

o Water supply is turned on

............................... . ,,,,,_,_,,

• Water line is connected securely and fittings and

crossover tube grommets do not leak

e Float is adjusted for proper water level

o Pulley alignment is OK Belt tension is OK (See

page 13)

o Pads are correctly installed (See page 13)

= Blower and both pad motors are plugged into

receptacles

o All louver clips are snapped tight

STARTUP CHECK LIST

To check out the installation follow this startup

procedure Set the control to each position and check

operation per the following chart, Be sure to open

windows or vents_,

OPERATION WITH SEARS SWITCH 32-6251

Switch

Off

Low Veftt

High Vent

Low Cool

High Cool

(Five Position)

Blower

Motor

Off

Low

High

Low

High

Pad

Motor_

Off

Off

Off

On

On