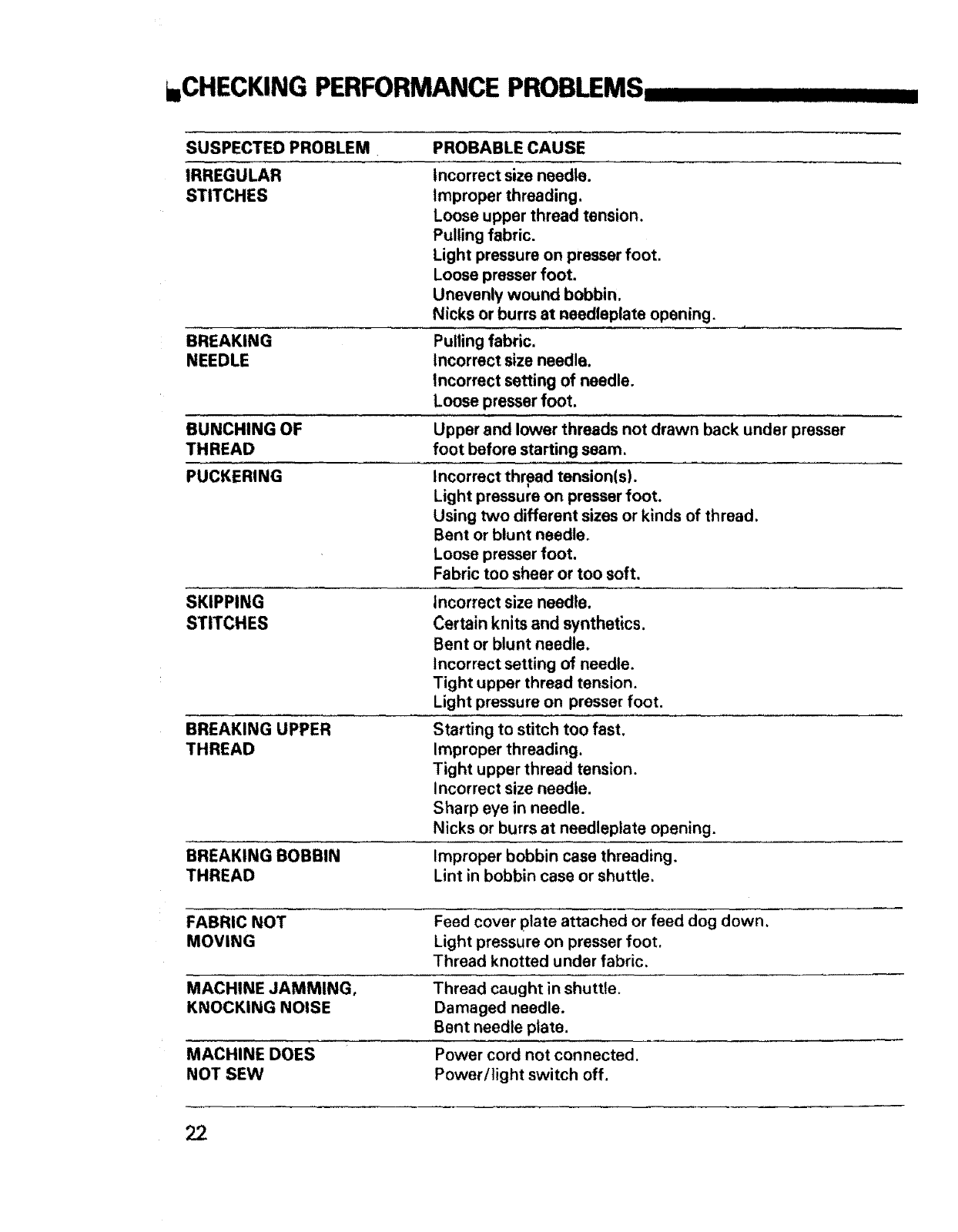

iCHECKING PERFORMANCE PROBLEMS I II

SUSPECTED PROBLEM

IRREGULAR

STITCHES

BREAKING

NEEDLE

PROBABLE CAUSE

Incorrect size needle.

Improper threading.

Loose upper thread tension.

Pulling fabric.

Light pressure on presser foot,

Loose presser foot.

Unevenly wound bobbin.

Nicks or burrs at needleplate opening.

Pulling fabric.

Incorrect size needle.

Incorrect setting of needle.

Loose presser foot.

BUNCHING OF Upper and lower threads not drawn back under presser

THREAD foot before starting seam.

PUCKERING Incorrect thread tension(s).

Light pressure on presser foot.

Using two different sizes or kinds of thread,

Bent or blunt needler

Loose presser foot.

Fabric too sheer or too soft.

SKIPPING

STITCHES

BREAKING UPPER

THREAD

BREAKING BOBBIN

THREAD

Incorrect size needle,

Certain knits and synthetics.

Bent or blunt needle.

Incorrect setting of needle.

Tight upper thread tension.

Light pressure on presser foot.

Starting to stitch too fast.

Improper threading,

Tight upper thread tension.

Incorrect size needle.

Sharp eye in needle.

Nicks or burrs at needleptate opening.

Improper bobbin case threading.

Lint in bobbin case or shuttle.

FABRIC NOT

MOVING

MACHINE JAMMING,

KNOCKING NOISE

MACHINE DOES

NOT SEW

Feed cover plate attached or feed dog down.

Light pressure on presser foot.

Thread knotted under fabric.

Thread caught in shuttle.

Damaged needle.

Bent needle plate.

Power cord not connected,

Power/light switch off.

22