32 VA Series Indoor LS Manual

Air Intake Assembly

The air intake system consists of a field supplied 4

inch diameter stainless steel, Schedule 40 PVC, ABS

or CPVC pipe. A maximum 6 feet of semi-rigid

flexible aluminum ducting can also be used. Foil

wrapped dryer vent and cell core products are not

authorized.

The air intake has a zero clearance to combustibles.

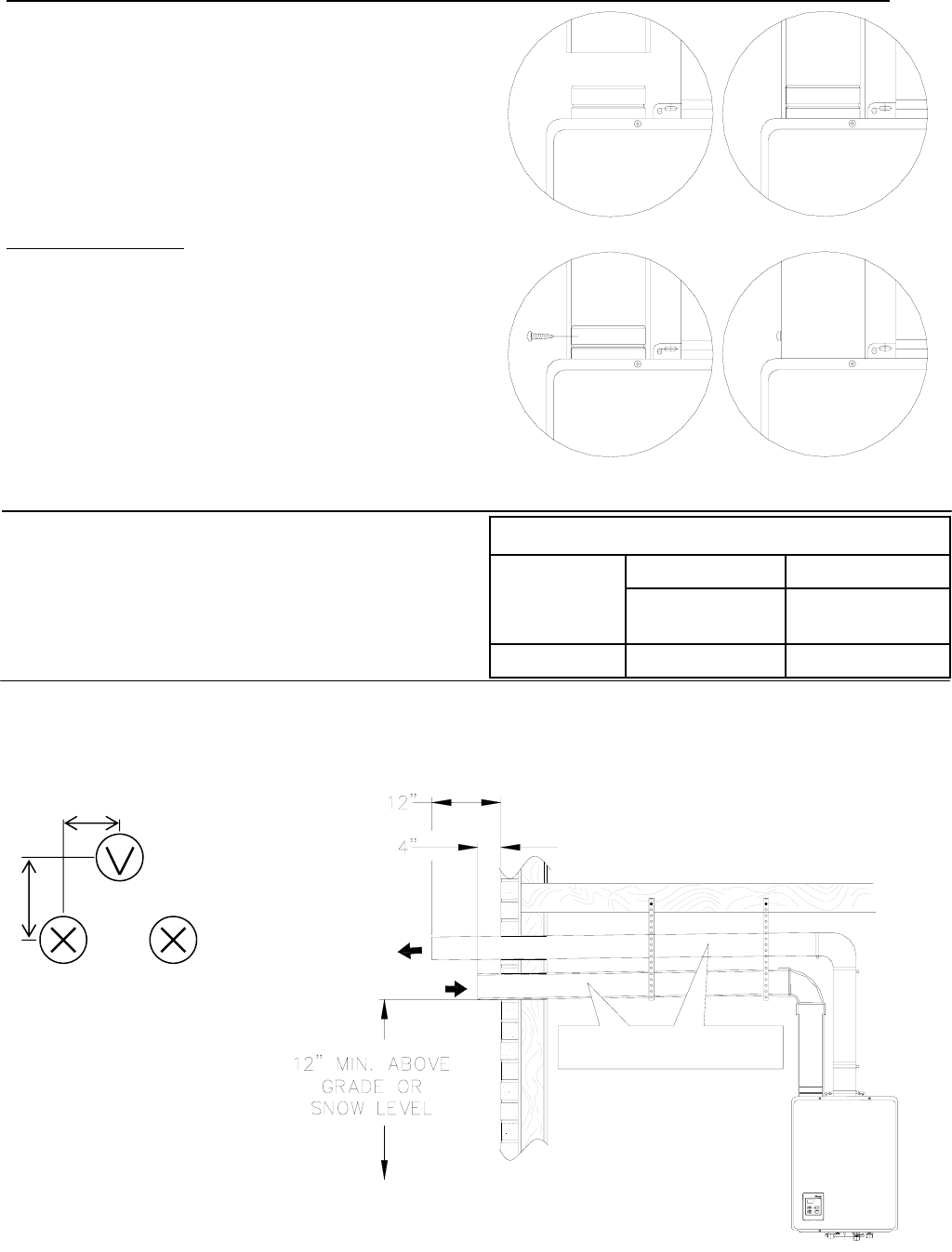

Air Intake Connection

1. Drill 2 small holes at the end of the air intake

pipe.

2. Slide the pipe over the air intake terminal.

3. Using a level, ensure the pipe is straight up and

down.

4. With self tapping screws, attach the pipe to the air

intake terminal.

5. Apply a bead of silicone around the pipe and air

intake terminal, ensuring an air tight connection.

Exhaust Pipe Assembly

Refer to the manufacturer’s installation instructions for

the specific exhaust vent system.

Venting Clearances to Combustibles

Vent Size

Enclosed Unenclosed

Horizontal &

Vertical

Horizontal &

Vertical

4" (102 mm) 4" (102 mm) 1" (26 mm)

4

3

1

2

COMBUSTION AIR /

INTAKE

EXHAUST

SLOPE INTAKE AND EXHAUST

TOWARD OUTSIDE TERMINATION

MINIMUM 1/4" PER FOOT

Horizontal Terminations

The air intake must be located in relation to the exhaust as shown below. The air intake must angle 1/4 inch per

foot to the termination to prevent entry of rain.

Flue Installation (R98LSi, R98LSi-ASME)

8”

6”

Intake

Optional

Intake

Vent

The vent termination and air

intake must be in the same

pressure zone and face the

same direction.