Please also take into account any fitting that could restrict flow such as water meters, softeners etc.

Connection to the unit – Use 22mm compression for all connections. Use gunmetal, DZR or brass fittings,

noting local water conditions.

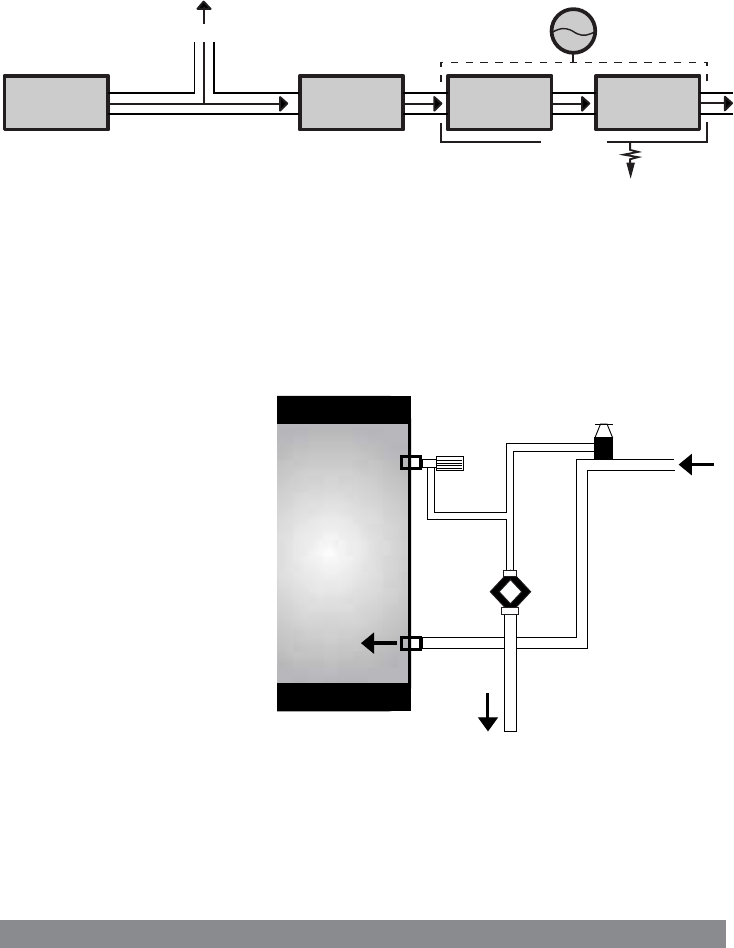

COLD MAINS COMPONENT LAYOUT

No valve is to be fitted between the expansion valve and the cylinder, except a drain point.

It is recommended that a stop cock is fitted to the above to facilitate servicing. Install before the

pressure reducing valve. Always fit a drain tap in an appropriate position for drain down as low as

possible.

DON’T USE MONOBLOC MIXERS IF THE COLD SERVICE IS UNEQUALISED AS IT WILL BACK – PRESSURISE

THE UNIT AND RESULT IN DISCHARGE.

PRESSURE REDUCING

VALVE/FILTER

NON RETURN VALVE PRESSURE GAUGE

EXPANSION VESSEL

(OPTIONAL)

DRAIN POINT

EXPANSION VALVE

COLD TAPS

COLD FEED

22mm

EXPANSION

VALVE

22mm

TUNDISH

15mm

15mm

PRESSURE AND

TEMPERATURE

RELIEF VALVE

2

DISCHARGE

Both the pressure and temperature

relief valve fitted to the unit and

the expansion valve supplied loose

must be arranged to comply with

G3 regulations and each discharge

into an open (visible) tundish.

A 300mm vertical drop of 22mm

diameter pipe must be fitted to the

tundish.

NB: THE TUNDISH AND DRAIN

MUST BE POSITIONED AWAY FROM

ELECTRICAL DEVICES.

ALWAYS CONSULT THE REGULATIONS!

IMPORTANT: Discharge arrangements are the responsibility of the installer and reference to current

building regulations should always be made. Applied Energy Products Ltd. offers the foregoing as

guidelines only.

The main purpose of discharge pipework is to allow full flow from relief valves to be accumulated and

safely routed to a point outside the building at low level.

New Stainless imp_alt 2/15/05 12:15 PM Page 3