4

1. Burner Inspection.

Clean the main burners and air louvers of dust, lint

and debris. With burner in operation, make a visual

check of the burner flame and the pilot flame (when

equipped). Yellow flames indicate some restriction of

combustion air openings. A bright orange, luminous

flame is not normal and can cause sooting under

prolonged operation. Should this condition be ob-

served, contact immediately a qualified service agency

to correct the problem.

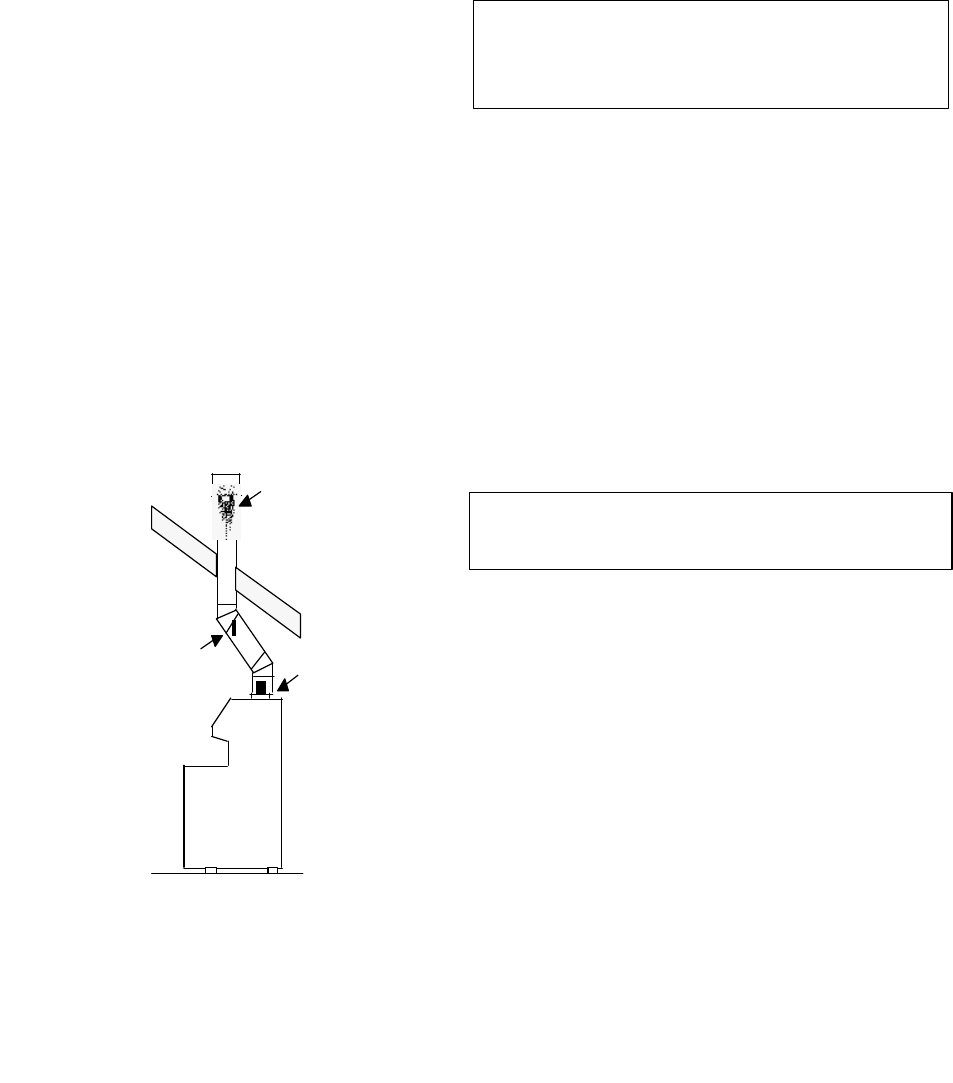

2. Venting System Inspection.

Visually inspect the venting system. Make sure the

vent connections are secure and have not become

disengaged. Look for any indication of corrosion, or

carbon (soot) streaks which could cause leakage of

products of combustion into the living space. Inspect

the vent terminal outside the building. Make sure it is

not damaged to cause blockage or restriction of the flue

gas. Observe for any indication of soot. The presence

of soot accumulation in the vent terminal would indicate

an abnormal operating condition. This should be

investigated and corrected by a qualified service

agency.

CORROSION

SOOT

DISENGAGED

Fig. #8204.0

3. Circulator (Water Pump) Inspection.

The circulator is permanently lubricated and thus,

will not require any lubrication. Inspect for evidence of

water leakage. This should be corrected to prevent any

possible damage to electrical components of the boiler.

CAUTION: In case of a prolonged power failure during

freezing weather conditions, boiler and piping system

must be drained completely to avoid possible damage

to the heating system.

To prevent the potential freezing damage to the

heating system, it is recommended that the following

system shut down procedure be performed.

SYSTEM SHUT DOWN PROCEDURE

1. Set the room thermostat to "OFF" or the lowest

setting.

2. Turn off all electric switches to the boiler.

3. Turn off all gas valves supplying gas to the boiler.

Refer to operating instruction label on the boiler.

4. Shut off the water supply to the boiler piping system

loop.

5. Open drain valve on the boiler to remove water

from the boiler and the piping circuits.

NOTE: It may be necessary to open the purge valves

and/or manual air vents to facilitate complete drainage

of water from the heating system.

4. Service Assistance.

If service is required on the boiler, contact your

local service agency or Raypak, Inc. can refer you to the

proper qualified service agency. It is important and very

often will save time if you state the model number, serial

number and type of gas used. This information will be

found on the nameplate of the boiler.

Raypak, Inc., 31111 Agoura Road, Westlake Village, CA 91361-4699 (818) 889-1500 FAX (818) 889-4522

Litho in U.S.A. www.raypak.com