R

ELIABILITY.

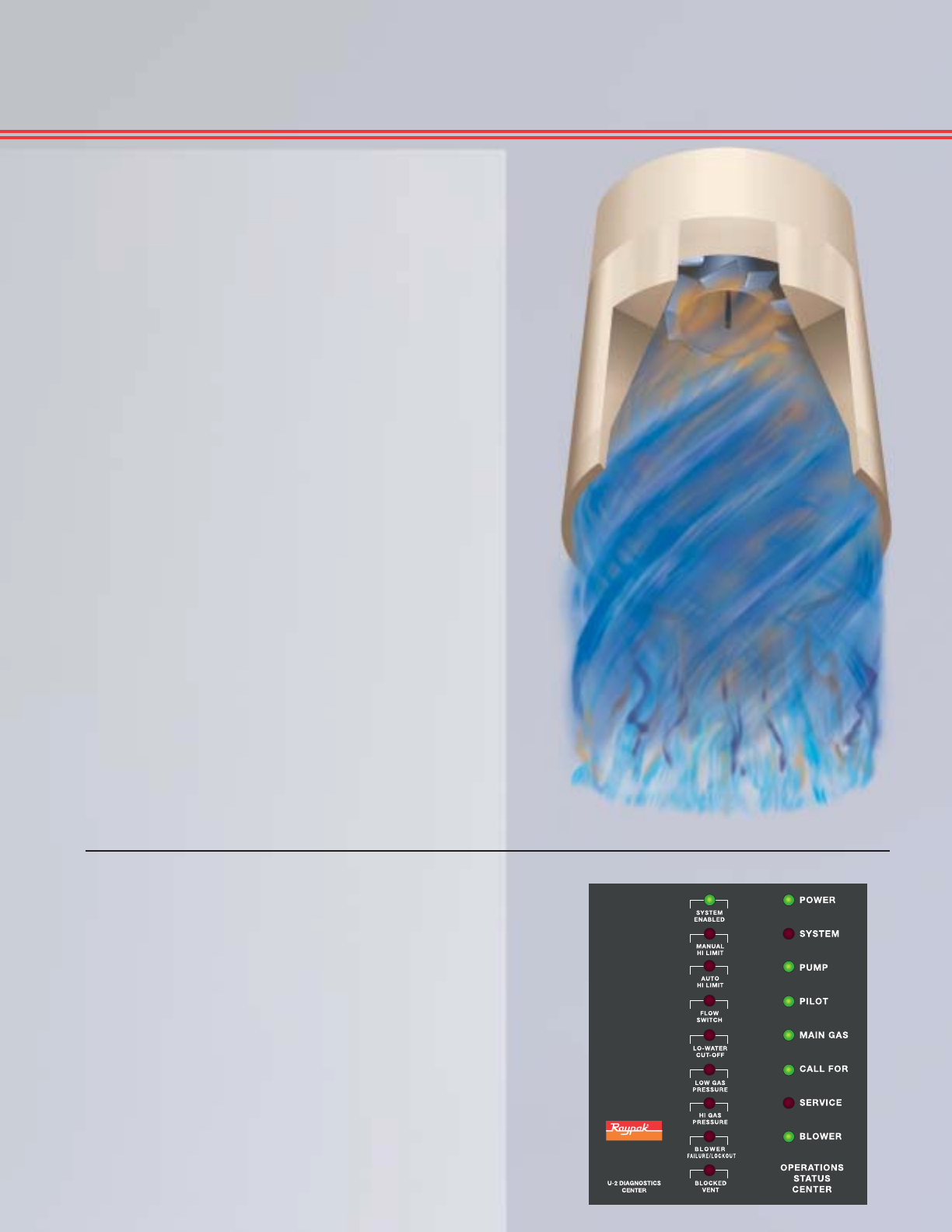

ADVANCED BURNER TECHNOLOGY

The heart of any boiler is the burner. It’s a critical

component that’s got to be designed right. That’s

why Raypak spent over four years perfecting the

ADB burner. The result is an industrial grade, fan-

assisted burner that provides superior perfor-

mance and is practically indestructible.

Standard high efficiency boilers use burners that

are either flimsy flame retention screens that burn

out, or radial perforated burners that eventually

clog and operate at reduced efficiencies. Unlike

these burner designs, the patented advanced

design burner will not clog or burn out. In fact,

Raypak is so confident, the new burner head is

backed with a T

EN YEAR UNCONDITIONAL WARRANTY.

The ADB’s burner utilizes a solid metal bluff-body

burner head to generate a high-intensity aerody-

namically stabilized flame. The burner’s turbulent

mixing action reduces residence time and increas-

es flue gas recirculation. The result is clean, effi-

cient combustion with NOx emissions well within

the limits of the most restrictive air quality require-

ments.*

This is one tough burner and the warranty proves it.

* NOx emissions:

0-30 ppm depending on combustion air quality and

gas composition.

ERROR

HEAT

CENTRAL POINT WIRING AND DIAGNOSTICS

Raypak boilers have a well earned reputation for

being easy to service. The ADB is no exception. In

fact, the ADB sets a whole new standard for ser-

viceability – because it’s the first commercial boiler

to incorporate central point wiring (CPW).

Unlike older control technologies, CPW individually

monitors each and every boiler control and safety

function. Using an intuitive LED display referred to

as the Operation Status Center, CPW gives split-

second feedback on boiler firing status. Should

service be required, the ADB will even indicate

which component requires attention by illuminat-

ing the appropriate fault LED located on the ADB’s

U-2 Diagnostics Panel.