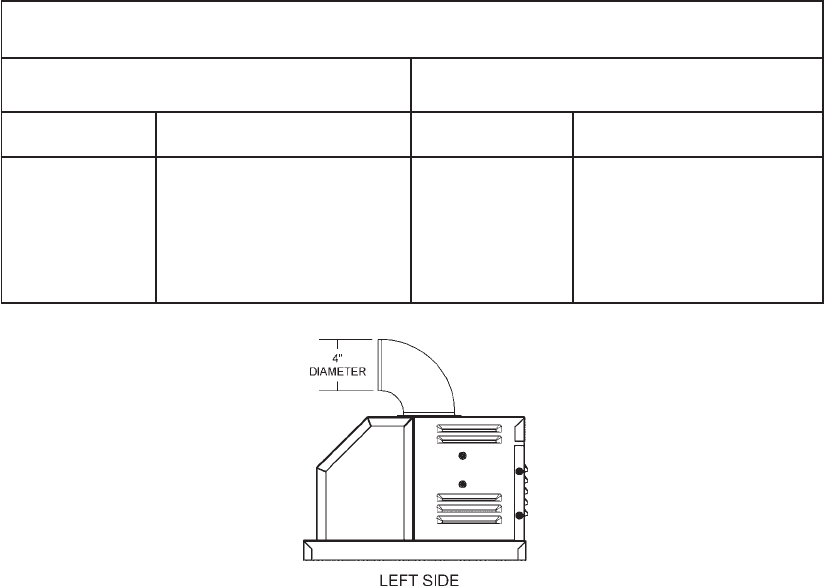

VENTING

The vent pipe must be the same size or larger than what is indicated. The D-2 Power Vent are

capable of 360-degree discharge rotation and operate with a positive vent static pressure and

with a vent gas temperature less than 400°F. The total length of horizontal run shall not

exceed an equivalent of 40 feet including termination cap. For all cases, each 90-degree

elbow reduces the maximum horizontal vent run by 10 feet and each 45-degree elbow in the

vent run reduces the maximum vent run by 5 feet. See the table for maximum vent lengths

using 90-degree and 45-degree elbows. The D-2 Power Vent uses positive pressure to push

flue gases through the vent pipe to the outside. The vent must be installed to prevent the flue

gas leakage. Care must be taken during assembly to insure that all joints are sealed properly

and are airtight.

The vent must be installed to prevent the potential accumulation of condensate in the vent

pipes. It is recommened that:

a) The vent be installed with a slight downward slope of not more than 1/4” per foot of

horizontal run to the vent terminal.

b) The vent be insulated through the length of horizontal run.

For appliances installed in extreme cold climate, it is recommended that:

a) The vent be installed with a slight upward slope of not more than 1/4” per foot of

horizontal run to the vent terminal. In this case, an approved condensate trap must

be installed per applicable codes.

b) The vent be insulated through the length of the horizontal run.

Reduced Maximum Equivalent Vent Run (feet)

90 degree elbows 45 degree elbows

Quantity Maximum Length Quantity Maximum Length

130 135

220 230

310 325

5

Fig #9357