16

shipped loose. The full open position is appropriate for

most systems, and ensures adequate flow through the

boiler.

If system flow is inadequate, (indicated by excessive

temperature drop through the system) the bypass

valve can be throttled slightly. Care must be taken

against over-throttling which may lead to inadequate

flow through the boiler and boiler harmonics (a hum-

ming sound from the heat exchanger).

If adequate system flow cannot be obtained without

causing harmonics, an additional pump is required.

The factory-mounted circulator will provide adequate

water flow for systems designed at a 20°F temperature

drop, and system pressure drop or head not exceed-

ing that which is shown in Table J.

When the total system head exceeds the available

head pressures, a primary/secondary pumping system

is recommended.

The minimum boiler operating temperature should be

105°F. When operating at low temperature applica-

tions, ∆T (temperature rise) must be 20°F or less.

Propylene glycol solution is commonly used in the

heating system when freeze protection is required.

This will affect the system design and pump perform-

ance. As a rule of thumb, 50% solution of propylene

glycol will require the system flow (gpm) to increase by

14%, and the system head (ft/WC) by 23% in order to

maintain the same heat transfer load.

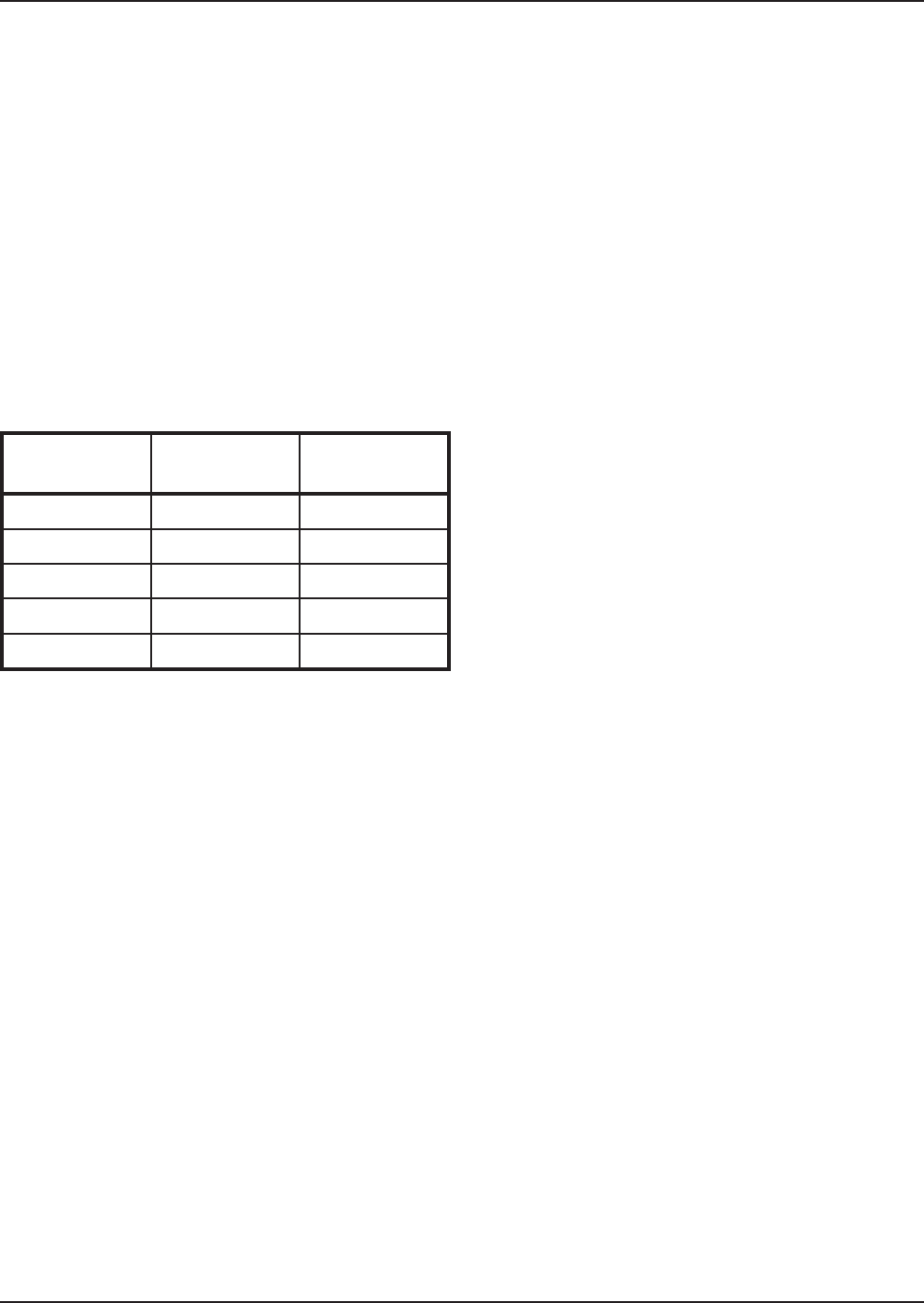

Model No.

System Flow

(gpm)

Max. System

Head (ft/WC)

H-0042 3.5 8.0

H-0066 5.3 8.5

H-0090 7.3 6.5

H-0135 11.0 10.0

H-0180 14.6 7.0

Table J: System Pressure Drop

Systems with multiple zones may require an addition-

al circulator. Consult manufacturer's data for valve

pressure drops. When an indirect water heating sys-

tem is used, it is recommended that a separate

circulator be installed to meet the required flow and

pressure drop conditions of the indirect water heater.

We recommend that the make-up water from the cold

water line have a check valve, gate valve, and feedwa-

ter regulator set at 12 psi. Install unions and gate or

ball valves at inlet and outlet connections at the boiler

to facilitate servicing.

The pressure relief valve is mounted on the boiler and

must be piped to a drain. We recommend that all high

points be vented and that purge valves be installed. A

boiler installed above radiation level must be provided

with a low water cut-off device. See page 27 for wiring

hook-up.

The boiler, when used in connection with a refrigera-

tion system, must be installed so that the chilled

medium is piped in parallel with the boiler with appro-

priate valves to prevent the chilled medium from

entering the boiler.

The boiler piping system of a hot water heating boiler,

that is connected to heating coils located in air han-

dling units where they may be exposed to refrigerated

air circulation, must be equipped with flow control

valves or other automatic means to prevent gravity cir-

culation of the boiler water during the cooling cycle.

A diaphragm expansion tank should be installed in the

return line. A typical 8"-diameter expansion tank can

be used on models H-0042, and H-0066, and an 11"-

diameter expansion tank can be used on models

H-0090, H-0135 and H-0180. Consult tank manufac-

turer for correct sizing.