8

3. Except for carpeted flooring, boilers are certified

for installation on combustible floors.

4. For un-insulated hot water pipes, maintain a 2"

clearance, or consult local authority having juris-

diction.

Combustion/Ventilation Air

1. The boiler must be provided with adequate supply

of air for proper combustion and ventilation in

accordance with the latest edition of the National

Fuel Gas Code, ANSI Z223.1, or applicable provi-

sions of the local building codes.

2. Models 0042 and 0066 only: When the boiler is

installed in a confined space such as a utility room

or closet where all air is supplied from inside the

building, the boiler room must be provided with

two openings, each one having a minimum net

free area, in square inches as shown in Table C.

WARNING: Air supply to the boiler room must not

be affected by mechanical exhaust vents located in

other parts of the house, such as kitchen or

bathroom fans, or attic blowers. Mechanical exhaust

vents may create a negative pressure condition in

the boiler room that can become a hazard of

asphyxiation, explosion or fire.

CAUTION: Combustion air must not be

contaminated by corrosive chemical fumes which

can damage the boiler. Measures must be taken to

prevent the entry of corrosive chemical fumes to the

combustion and ventilation air supply. Such

chemicals include, but are not limited to, chlorinated

and/or fluorinated hydrocarbons such as found in

refrigerants, aerosol propellants, drycleaning fluids,

degreasers, and paint removers. Other harmful

elements may come from bleaches, air fresheners,

or mastics. Vapors from these types of products can

form corrosive acid compounds when burned in a

gas flame. The resulting acid condensate can

damage or substantially reduce the life of the heater.

It may be necessary to provide outside air directly to

the heater in order to avoid this problem.

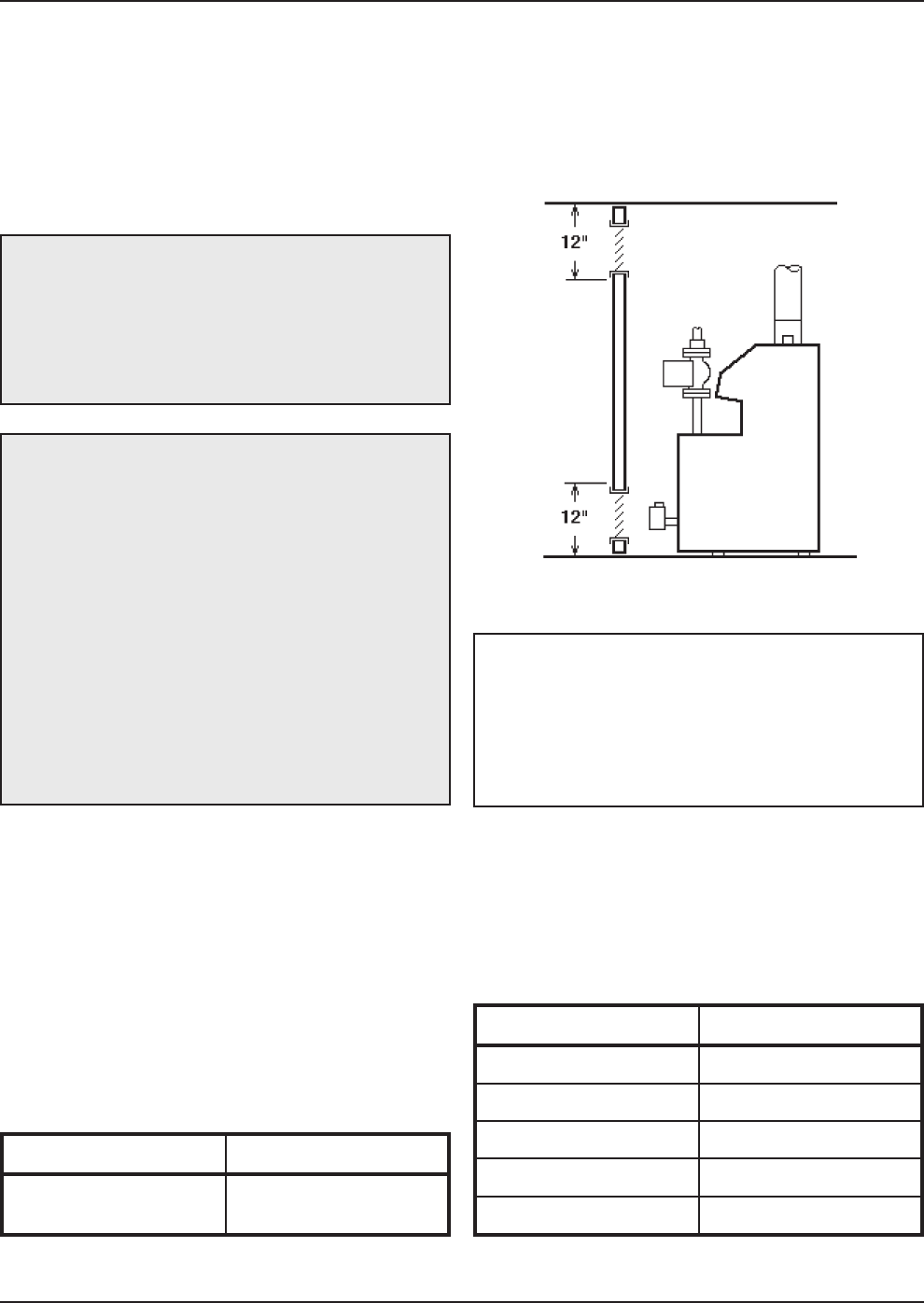

One opening shall be within 12" of the top, and the

other opening within 12" of the floor. If additional gas

appliances are installed in the same space, the total

input of all gas appliances installed in the same space,

must be considered in the calculation. Refer to the lat-

est edition of the National Fuel Gas Code for additional

r

equirements.

3. If the boiler room is located against an outside wall

and air openings can communicate directly with the

outdoors, the two openings on the outside wall must

each have a net free area as shown in Table D.

Model No. Sq. in. of Free Area

0042

0066

70

Table C: Minimum Net Free Area

NOTE: If louvers, grills or screens are used on the

openings, obtain the net free area requirements from

their supplier or manufacturer. If the design free area

of a louver is not known nor available, it shall be

assumed that wood louvers will have 20-25 percent

free area and metal louvers will have 60-75 percent

free area as specified in the National Fuel Gas Code.

Model No. Sq. in. of Free Area

0042 12

0066 18

0090 24

0135 35

0180 45

Table D: Minimum Net Free Area

Fig. 3: Location of Openings for

Combustion/Ventilation Air