Specifications

Heater Voltage 240 / 208 VAC Amps

KW Rating: @240V 5.0 kW High 21

3.3 kW Low 14

@208V 3.7 kW High 18

2.5 kW Low 12

D

imensions: 16”H x 21”W x 8”D

Weight: 22 lbs

GENERAL

Location of Heater

This heater has user controls. It may be desirable to reach

these controls after installation.

T

he direction of air flow should not be restricted by columns,

machinery, etc., and the air flow should wipe exposed walls

rather than blowing directly at them. When more than one

heater is used in a area, the heaters should be arranged so that

the air discharge of each heater supports the air flow of the oth-

ers to provide best circulation of warm air.

Mounting Height

When air flow of the heater is directed vertically, the minimum

mounting height is 6 feet, and the maximum mounting height is

15 feet. When the air flow of the heater is directed horizontally,

the minimum recommended mounting height is 6 feet, and the

maximum recommended height is 8 feet.

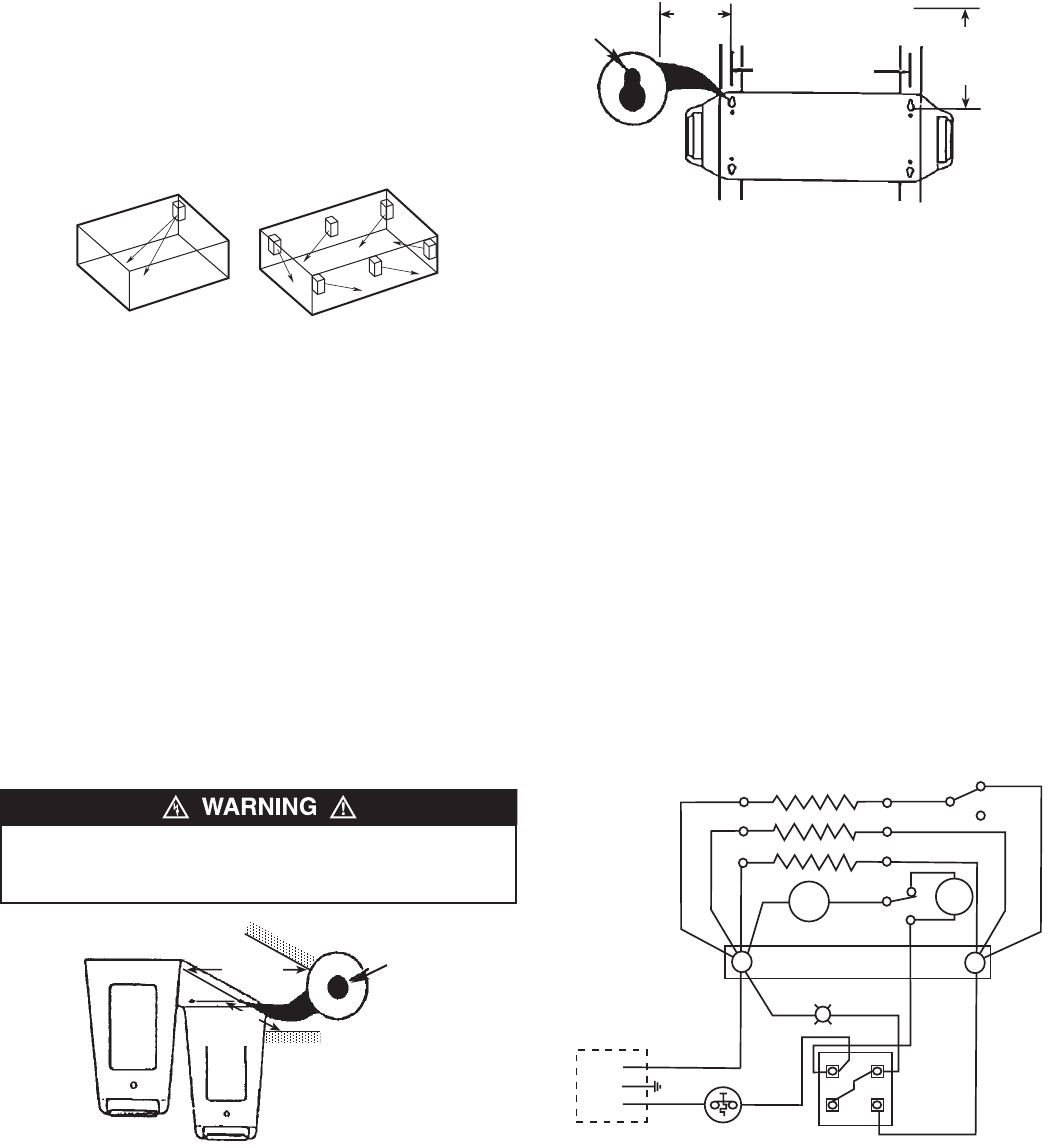

CEILING MOUNT

This heater may be mounted to any ceiling that will support the

weight of the heater.

First remove the mounting stand from the heater, then remove

four rubber grommets from stand. Secure stand to structural

members of ceiling with four 1/4” diameter bolts (not provided).

In wood joist use 1-1/2” long lag bolts. In steel beams use

machine bolts secured with nuts and lockwashers. Never use

bolts smaller than 1/4” diameter.

Replace the heater in the stand and tighten knobs to lock in

place. Two large rubberwashers go between heater and stand,

one on either side.

WALL MOUNT

SEE WARNING NO. 15.

This heater may be mounted on any wall that will support the

weight of the heater. First remove the mounting stand from the

heater, then remove four rubber grommets from stand. Secure

stand to structural members of wall with four 1/4” dia. X 1-1/2”

long lag bolts (not provided). In masonry walls use metal

expansion shields or toggle bolts. Never use bolts smaller than

1/4” diameter.

Replace the heater in the stand and tighten knobs to lock in

place. Two large rubber washers go between heater and stand,

one on either side.

CONNECTING THE POWER

Hardware Needed

You also will need the following hardware which you can pur-

chase from your local hardware store or electrical supply house:

• Enough 10 gauge copper wire to run power from the service

box to the heating unit. Copper wire must have a minimum

temperature rating of 60 degrees C. DO NOT USE

ALUMINUM WIRE WITH THIS UNIT.

• Proper wire connectors for your application. (See illustration

that follows.)

For certain applications, conduit may be required. Check local

electrical codes. Also, if you run the wiring in conduit and wish

to be able to turn the heater, be sure to purchase enough flexi-

ble conduit to allow the heater to be turned.

Loosen the two screws that secure the wiring compartment

cover to the upper right hand area of the back of the heater and

remove the cover.

Attach the cable connector to the cover as shown above and

slide the 10 gauge wire through the cable connector. Pull

enough of the wire through the connector so you will have

enough wire to work with when you make the connections.

TO PREVENT HEATER FROM POSSIBLY FALLING, DO NOT

USE KEYHOLE SLOTS FOR CEILING MOUNT APPLICA-

TION. SEE ALSO WARNING NO. 15.

2

MIN

8" TO

CEILING

TO WALL

MIN 8"

MIN. 8"

TO WALL

MIN. 8"

TO WALL

ELEMENTS FRONT

MIDDLE

REAR

HEAT SW.

HI

LOW

1

2

3

2

3

1

AUTO

FAN SW.

ON

TERMINAL BLOCK

6

4

INDICATOR LIGHT

MANUAL RESET

THERMAL LIMIT

BLACK

GREEN

BLACK

SUPPLY LEADS

WIRING COMPARTMENT

FAN

DELAY

MOTOR

L1

OFF

CYL

L2

THERMOSTAT

KEYHOLE

SLOT

M

OUNTING

H

OLES

A

RE 16” O.C.

USE

K

EYHOLES

F

OR WALL

MOUNTING

CIRCULAR

HOLE

USE CIRCULAR

HOLES FOR

CEILING MOUNT-

ING. DO NOT

USE KEYHOLES.