PV500-17 05-2000 Section 17

3

MAXIM

MAINTENANCE AND SAFETY INSPECTIONS

1. Establish a preventive maintenance program to

assure a longer water heater life.

2. The tank should be flushed at two- or three-

month intervals depending on water conditions

in your location. To flush, turn off electrical

disconnect switch to prevent the burner from

operating. Open the drain valve and allow

water to flow through the tank until it runs clear.

Close the drain valve and turn the electrical

switch back on. Draining two or three gallons

from the bottom of the tank on a weekly basis

will also help prevent the accumulation of

sediment. Water impurities consist of fine

particles of soil or sand which will settle out

and form a layer of sediment on the bottom of

the tank.

3. A scale of lime will normally form during

operation and will accumulate on the bottom of

the tank. Lime is formed from the natural

chemicals in the water which precipitate out

during heating cycles. Some water supplies

contain more of these chemicals than others

and scale buildup will occur more rapidly.

Other factors affecting scale buildup are the

amount of hot water used and temperature of

the water. The more hot water used, the

more fresh water containing scale-forming

chemicals is brought into the tank. As the

temperature of water increases, the rate of

scale deposition will be increased.

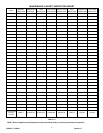

4. The tank will have a handhole for inspection

and cleaning. (See Figure 17-1, page 1.) To

inspect tank for scale buildup, remove the

handhole cover. If scale is present, it can be

loosened with a high pressure stream of

water. The smaller pieces can be flushed

through the drain and the larger pieces

removed by hand through the handhole. The

frequency of inspections will be determined

by the rate of scale buildup. Intervals of 30-

60 days is recommended.

5. If a firetube leaks for any reason, consult

factory for instructions.

NOTE: Condensate coming from the tubes on

a cold start is normal and does not

indicate a leaking tube.

6. Regularly inspect the bottom tubesheet.

Inspect the SCALEGUARD

tubesheet

insulator for holes or areas that may have

pulled away from tubesheet. Repair or

replace as required.

CARBON MONOXIDE WARNING:

CAUTION: IMPROPER COMBUSTION MAY CAUSE SERIOUS INJURY.

PVI recommends a seasonal or annual combustion check-out be performed by a

qualified service agency to ensure safe and efficient operation.

Periodic Inspection of Operational Components

Periodic inspection and check-out of the burner ignition, control system, and fuel valve operation

(for tight close-off) should be made. Refer to the burner installation instruction for

recommendations.

1. Examine the venting system at least once each

year for proper connections, alignment and

corrosion. The blower inlet will collect dust

from the air during operation. Disconnect the

power to the heater and clean the blower

wheel when necessary.

Inspect all parts and make replacements when

necessary. Check wiring for loose connections

and burned wires.