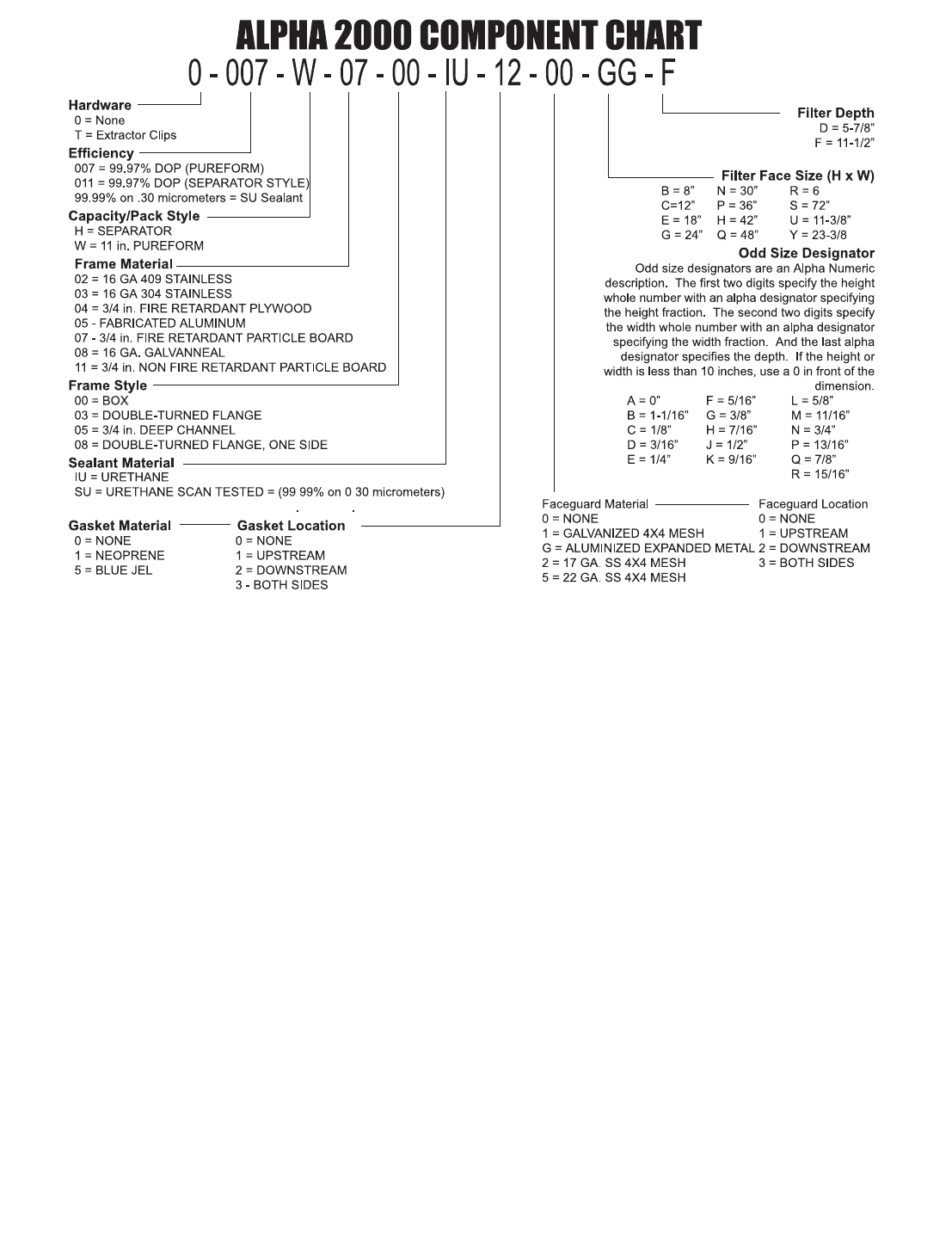

Frame Materials: Alpha 2000 Filters are available in a variety of wood and metal frame materials such as parti-

cle board, plywood, galvanized steel and stainless steel.

Gasket and Fluid Seal: The standard gasket seal is 0.75” x 0.25” neoprene for installation on either the

upstream, downstream or both sides of the filter. The standard Fluid Seal is Flanders Blu-Jel® Seal which is a

two - part silicone material suitable for temperatures up to 390°F.

Faceguards (Optional): Faceguards are used to protect the filter media from mechanical damage. The typical

faceguard material is expanded aluminized steel. Galvanized 4 x 4 mesh welded wire and Type 304 stain-

less steel are also available.

Underwriters Laboratories Qualification: Alpha 2000 Filters are either UL900 Class 1 or Class 2 listed depending

on materials of construction.

UL 900 Class 1 — Flanders HEPA Filters are UL 900 Class 1 rated except those filters manufactured with non-

fire-retardant wood frames. Upon request, the filter will have a stamp indicating compliance with UL 900 Class

1.

UL 586 — UL 586 is typically required for Nuclear Grade HEPA Filters. Many of the Flanders non-Nuclear HEPA

Filters meet the requirements of UL 586. To be listed under UL 586, filters must be submitted to Underwriters

Laboratories for extensive testing including spot flame and environmental exposure to heated air. Upon request,

a numbered UL 586 label certifying that the filter meets Standard 586 can be applied to the filter (maximum size

is 24” x 30”).

Banks: Alpha Frames are designed for Alpha 2000 filters in built-up filter banks. Each filter is secured in the

frame with four bolt-type fasteners that either compress the gasket or press the knife edge into the gel in the fil-

ter channel to maintain a leak-tight seal.

Surelock HEPA Filter Housings are recommended for side-access applications. The filters are sealed in place

with either spring-loaded swing arm assemblies or a locking mechanism. The swing arm assemblies or locking

mechanism either compress the gasket or press the knife edge into the gel in the filter channel to maintain a

leak-tight seal.

3