30

10.0 Installation

© Baxi Heating UK Ltd 2012

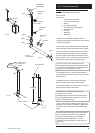

Fig. 44

Pressure Relief Valve

Fig. 43

Wall Plate

Suggested Lifting Points

shown as shaded area

10.3 Fitting The Boiler

1. Remove the sealing caps from the boiler connections.

NOTE: A small amount of water may drain from the

boiler once the caps are removed.

2. Lift the boiler as indicated by the shaded areas. The boiler

should be lifted by TWO PEOPLE. Engage the slots at the

top rear of the boiler on the wall plate (Fig. 43) (see Safe

Manual Handling page 5).

3. Insert the sealing washers between the valves and pipes

on the wall plate and the boiler connections. The rubber

washers must be used on the gas connections.

4. Tighten all the connections and fit the filling loop.

10.4 Fitting the Safety Pressure Relief

Discharge Pipe (Fig. 44)

1. Remove the discharge pipe from the kit.

2. Determine the routing of the discharge pipe in the vicinity

of the boiler. Make up as much of the pipework as is

practical, including the discharge pipe supplied.

3. The pipework must be at least 15mm diameter and run

continuously downwards to a discharge point outside the

building. See section 6.7 for further details.

4. Utilising one of the sealing washers, connect the discharge

pipe to the adaptor and tighten the nut.

5. Complete the discharge pipework and route it to the

outside discharge point.

IMPORTANT: Make all soldered joints before connecting

to the pressure relief valve.

10.5 Condensate Drain (see section 7.7)

1. Connect the condensate drain to the trap outlet pipe.

Ensure the discharge of condensate complies with any

national or local regulations in force (see British Gas

“Guidance Notes for the Installation of Domestic Gas

Condensing Boilers”.

2. The connection will accept 21.5mm (

3

/

4

in) plastic overflow

pipe which should generally discharge internally into the

household drainage system. If this is not possible, discharge

into an outside drain is acceptable.

Safety Pressure

Relief

Remove Sealing Caps from

under the Boiler after lifting

into position

Sealing

Washers