14 PFAFF

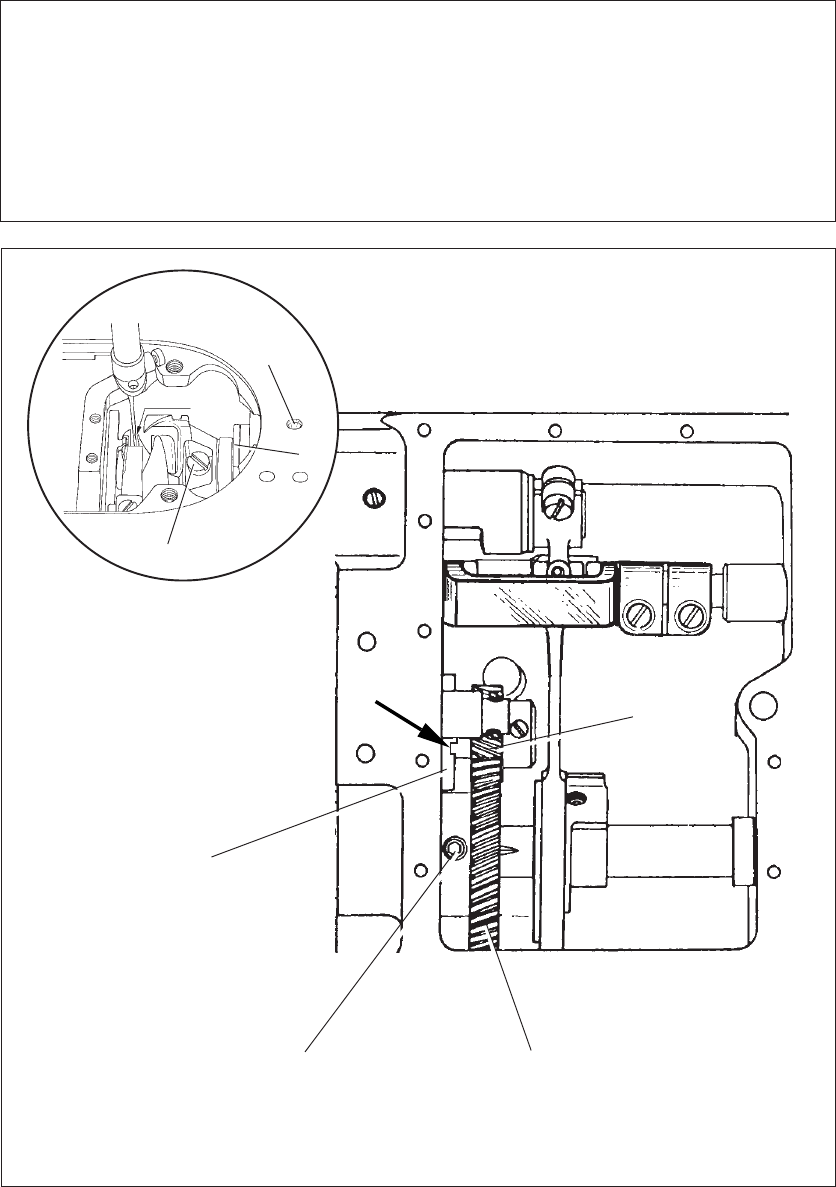

9 Eccentric hook shaft bearing and hook-to-needle clearance

● Loosen screws 1 and 2.

● Turn bearing 3 according to requirement 1.

● Set the hook lightly against spin disc 4, shift bearing 3 - without turning it - according to

requirement 2 and tighten screws 1 and 2.

● Position gear 5 (screws 6) according to requirement 3.

3

6

5

7

1

4

2

0,1 mm

Requirement

1. The notch in bearing 3 (see arrow) must be visible from below.

There must be a slight but still noticeable play between gears 5 and 7.

2. With the hook set lightly against spin disc 4 and the hook point opposite the center line

of the needle, there must be clearance of less than 0.1 mm between the hook point

and the clearance cut of the needle.

3. Gear 5 must be flush with gear 7.