1

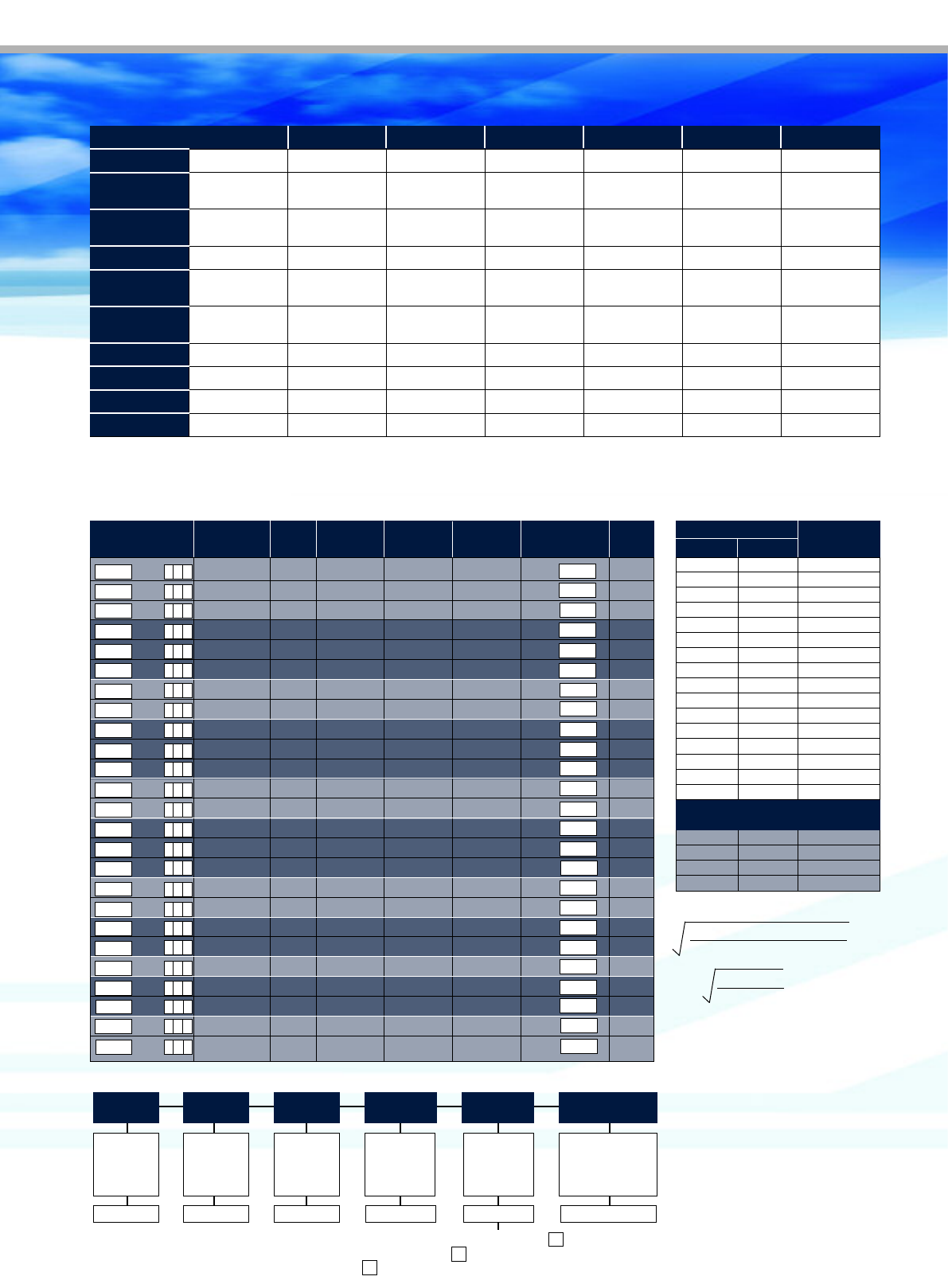

15 0.38

2 29 0.53

3 44 0.65

4 58 0.76

5 73 0.85

6 87 0.93

7 100 1.00

8 116 1.07

9 131 1.13

10 145 1.19

11 160 1.25

12 174 1.31

13 189 1.36

14 203 1.41

15

218 1.46

16 232 1.51

17

247 1.56

18 261 1.60

19 275 1.65

20 290 1.70

L/s

Product selection

psi g

Model Pipe Size m

3

/min m

3

/hr cfm

Replacement

Element Kit

No.

bar g

Line Pressure

Correction

Factor

Stated flows are for operation at 7 bar (g) (102 psi g) with reference to 20°C, 1 bar (a), 0% relative

water vapour pressure. For flows at other pressures apply the correction factors shown.

System Operating Pressure

Nominal pressure

8.5 bar g

7 bar g

T

o f

ind the Corr

ection factor for 8.5 bar g (122psi g) =

=

= 1.10

W

hen ordering an AO/AA filter for pressures above 16 bar g (232 psi g), use

manual drain. Replace F with M in product code. e.g. 015BBFX now 15BBMX

GRADE

MODEL PIPE

SIZE

CONNECTION

TYPE

DRAIN OPTION

INCIDENT MONITOR

OPTION

A

O / AA grade filters for use up to 16 bar g (232 psi g) are supplied with a float drain as standard.

For pressures of 16 to 20 bar g (232 to 290 psi g) a manual drain must be used. ACS / AR / AAR

grade filters are supplied with a manual drain as standard.

AO

AA

AR

AAR

A

CS

3 digit

c

ode

shown

above

Letter

denotes

pipe size

B = BSPT

N = NPT

F = Fl

oat

M = Manual

X = None

I = Incident Monit

or

AA

010 A B F X

F

M

M

Note:

Not available

on models 005 & 0010

Filt

er sel

ection e

xampl

e

Selecting a filter model to match a system flow rate and pressure.

Ex

ample:

Sy

stem f

lo

w 1050 m

3

/hr at a pr

essur

e of 8.5 bar g

1. Obtain pressure correction factor from table or calculate factor

using method shown. Correction factor for 8.5 bar g = 1.10

2. Divide system flow by correction factor to give equivalent flow rate

at 7 bar g 1050m

3

/hr ÷ 1.10 = 955 m

3

/hr (at 7 bar g)

3. Select a filter model from the above table with a flow rate above

or equal to 955 m

3

/hr

. Filter model selected : 045

4.

Select f

iltration grade General purpose filter required,

gr

ade A

O selected : Model A

O045

5. Select pipe connection & Thread type

System uses 2" piping and BSP threads : Model AO045HB

6. Select drain type and other options.

Automatic float drain required, differential pressure monitor not

r

equir

ed. Model A

O045HBFX Final Filter Model Selected - A

O045HBFX

Correction factors

Filtration grades

WS AO AA ACS OVR AR AAR

Filter Type Bulk Liquid Removal Coalescing Coalescing Oil Vapour Removal Oil Vapour Removal Dry Particulate Dry Particulate

Particle removal

(inc water & oil aerosols)

N

/A

D

own to 1 micron

D

own to 0.01 micron

N

/A

N

/A

D

own to 1 micron

D

own to 0.01 micron

M

ax Remaining Oil

Content at 21°C (70°F)

N

/A

0

.6 mg/m

3

0.5 ppm(w)

0

.01 mg/m

3

0.01 ppm(w)

0

.003 mg/m

3

0.003 ppm(w)

0

.003 mg/m

3

0.003 ppm(w)

N

/A

N

/A

Filtration Efficiency >92% 99.925% 99.9999% N/A N/A 99.925% 99.9999%

Test Methods Used ISO 8573.9

I

SO 8573.2

ISO 8573.4

I

SO 12500-1

I

SO 8573.2

ISO 8573.4

I

SO 12500-1

ISO 8573.5 ISO 8573.5 ISO 8573.4 ISO 8573.4

ISO 12500-1 Inlet

Challenge Concentration

N

/A

4

0mg/m

3

1

0mg/m

3

N

/A

N

/A

N

/A

N

/A

I

nitial dry

differential pressure

N/A <70 mbar (1.5psi) <140 mbar (2psi) <140 mbar (2psi) 350 mbar (5psi) <70 mbar (1.5psi) <140 mbar (2psi)

Initial saturated

differential pressure

N

/A

<

140 mbar (2psi)

<

200mbar (3psi)

N

/A

N

/A

N

/A

N

/A

C

hange Element Every

N

/A

1

2 months

1

2 months

W

hen oil vapour is detected

6

000 Hrs

1

2 months

1

2 months

Precede with filtration grade

- W

S (for bulk liquid)

A

O

A

A

A

A

- A

R

Filt

er c

oding e

xampl

e

X

X

X

X

X

X

1

/

4" 6 0.4 22 13 010 grade 1

3

/

8" 6 0.4 22 13 010 grade 1

1

/

2" 6 0.4 22 13 010 grade 1

1

/

4" 10 0.6 36 21 010 grade 1

3

/

8" 10 0.6 36 21 010 grade 1

1

/

2" 10 0.6 36 21 010 grade 1

3

/

8" 20 1.2 72 42 015 grade 1

1

/

2" 20 1.2 72 42 015 grade 1

1

/

2" 30 1.8 108 64 020 grade 1

3

/

4" 30 1.8 108 64 020 grade 1

1" 30 1.8 108 64 020 grade 1

3

/

4" 60

3.6

216

127

025 grade 1

1" 60 3.6 216 127 025 grade 1

1" 110 6.6 396 233 030 grade 1

1

1

/

4" 110

6.6 396 233 030 grade 1

1

1

/

2" 110 6.6 396 233 030 grade 1

1

1

/

4" 160 9.6 576 339 035 grade 1

1

1

/

2" 160 9.6 576 339 035 grade 1

1

1

/

2" 220

13.2

792 466 040 grade 1

2" 220 13.2 792 466 040 grade 1

2" 330 19.8 1188 699 045 grade 1

2

1

/

2" 430

25.9

1548

911

050 gr

ade 1

3" 430 25.9 1548 911 050 grade 1

2

1

/

2" 620 37.3 2232 1314 055 grade 1

3"

620

37.3

2232

1314

055 gr

ade

1

grade 005A

grade 005B

grade 005C

grade 010A

grade 010B

grade 010C

grade 015B

grade 015C

grade 020C

grade 020D

grade 020E

gr

ade 025D

grade 025E

grade 030E

gr

ade 030F

grade 030G

grade 035F

grade 035G

gr

ade 040G

grade 040H

grade 045H

gr

ade 050I

grade 050J

grade 055I

gr

ade 055J

9