Step Four Step Five

WIRING INSTALLATION

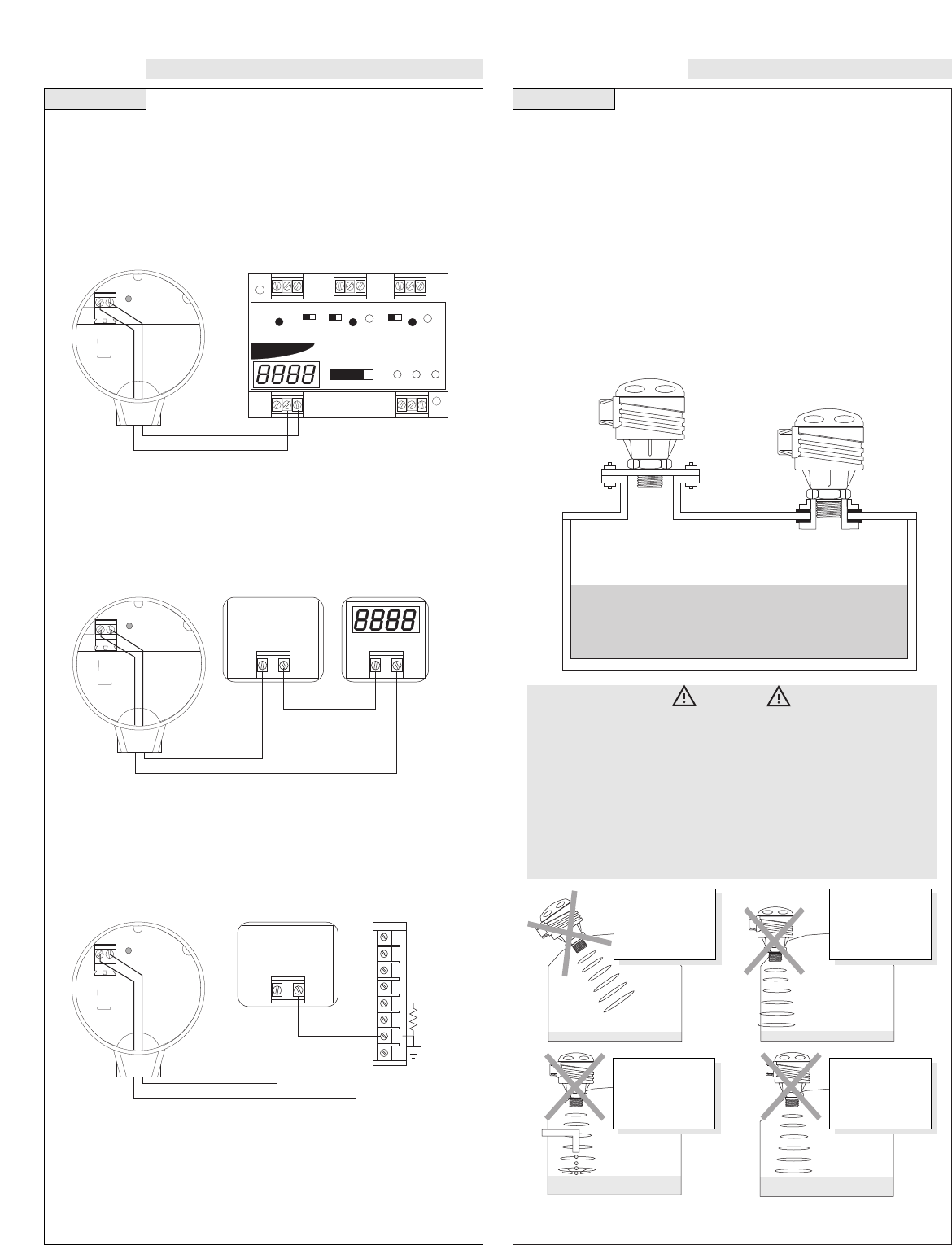

The LVCN-90 transmitter may be installed through the top wall of a

tank. Installation requires a 3/4" NPT fitting or blind flange.

1. Install the appropriate 3/4" fitting in the top wall of the tank. Prior

to installation, make sure that the fitting has been installed prop-

erly and checked for leaks. Use a proper sealant at the time of

installation to ensure a liquid-tight seal. Secondly, make sure that

the fitting’s threads are not damaged or worn.

2. Insert the Transmitter into the fitting and tighten to hand tight.

3. Always check for leaks prior to system start-up. To ensure proper

installation, a complete leak test and simulation of actual process

conditions should be preformed.

Flange Fitting

Installation Installation

Warning

Do not install the LVCN-90 in pressurized applications above 30

psi.

Always install the 3/4" Viton gasket with the LVCN-92. The

LVCN-92 G threaded version will not seal unless the gasket is

installed properly.erly and checked for leaks.

Use a proper sealant at the time of installation to ensure a liquid-

tight seal. Secondly, make sure that the fitting’s threads are not

damaged or worn.

Follow the instructions in Step 3 for wiring to the LVU-90.

1. Wiring to an OMEGA Continuous Controller (LVCN-51):

Connect the (+) terminal to the positive 24 VDC, 25 mA terminal

on the controller. Connect the (-) terminal to the GND terminal on

the continuous controller (See illustration below). Check LVCN-

51 instruction manual for setting the LVCN-51 for loop powered

operation.

2. Wiring to a Two-Wire Loop Powered Indicator:

The LVCN-90 requires 12-36 VDC power and an indicator which

receives a 4-20 mA current input. Connect the (+) terminal of the

LVCN-90 transmitter to the positive VDC terminal on the power

supply. Connect the (-) terminal on the LVCN-90 to the (+) ter-

minal on the loop indicator. Connect the (-) of the loop indicator

to the (-) of the power supply (See illustration below).

3. Wiring to a Typical PLC:

The LVCN-90 requires a PLC which provides a 12-36 VDC exci-

tation and receives a 4-20 mA current input. Connect the (+) ter-

minal of the LVCN-90 transmitter to the positive VDC power ter-

minal. Connect the (-) terminal on the LVCN-90 to the (+) chan-

nel on the PLC. Connect the (-) of the PLC to the (-) of the power

terminal (See illustration below).

* 250 Ω resistor typically internal to PLC

LATCH

ON OFF

PWR

RELAY 1

INVERT

DELAY

RELAY 2

INVERT

DELAY

4 20 OP

EASY CAL

UP DOWN SET

INPUT

0% 100%

OFF SET

SPAN

RLY1

RLY2A

RLY2B

POWER

4-20 mA

(-) (+)

GND

12-36 VDC

- +

- ++ -

DC Power

Supply

12-36 VDC

POWER

4-20 mA

(-) (+)

GND

12-36 VDC

- +

+ -

DC Power

Supply

12-36 VDC

Typical PLC

6

5

4

3

2

1

0

A

250Ω

POWER

4-20 mA

(-) (+)

GND

12-36 VDC

- +

VACUUM

Avoid

Interference from

side of tank

Do not

install at

an angle

Avoid

Interference from

obstructions in

tank

LVCN-90 will

not operate in

vacuum