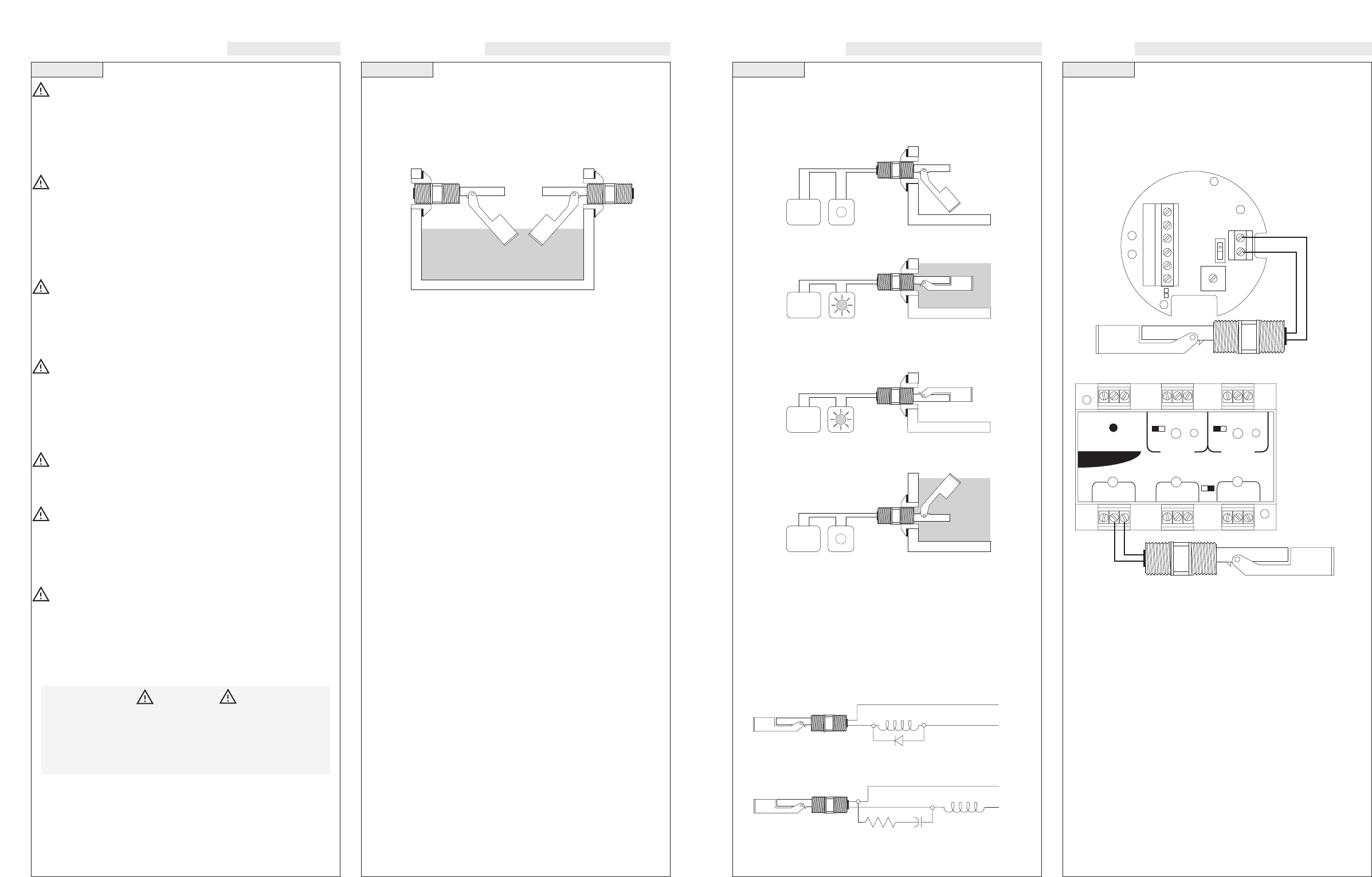

Step Two Step Three

SAFETY PRECAUTIONS INSTALLATION

About this Manual:

PLEASE READ THE ENTIRE MANUAL PRIOR TO

INSTALLING OR USING THIS PRODUCT. This manual

includes information on all models of horizontal mini-float level

switches from OMEGA ENGINEERING, LVH-200 series. Please

refer to the part number located on the switch label to verify the

exact model which you have purchased.

User’s Responsibility for Safety:

OMEGA ENGINEERING manufactures a wide range of liquid

level sensors and technologies. While each of these sensors is

designed to operate in a wide variety of applications, it is the user’s

responsibility to select a sensor model that is appropriate for the

application, install it properly, perform tests of the installed system,

and maintain all components. The failure to do so could result in

property damage or serious injury.

Proper Installation and Handling:

Because this is an electrically operated device, only properly

trained staff should install and/or repair this product. Use a proper

sealant with all installations. Never overtighten the sensor within

the fitting, beyond being hand tight. Always check for leaks prior to

system startup.

Material Compatibility:

The LVH-200 series switch is available in one wetted material.

Models LVH-200 series are made of Polypropylene (PP). Make

sure that the model you have selected is compatible with the appli-

cation liquid. To determine the chemical compatibility between the

sensor and its application liquids, refer to an industry reference

such as the Compass Corrosion Guide (available from Compass

Publications, phone 858-589-9636).

Temperature and Pressure:

The LVH-200 series switch is designed for use in application tem-

peratures up to 107.2 °C, and for use at pressures up to 100 psi.

Wiring and Electrical:

The supply voltage used for the LVH-200 series should never

exceed 120/240 volts AC / 30 volts DC @ 20 VA. CE mark ver-

sions should never exceed 30 Vrms and 42.2 Vpeak or 60 VDC.

Electrical wiring of the sensor should be performed in accordance

with all applicable national, state, and local codes.

Flammable, Explosive and Hazardous Applications:

The LVH-200 seriesshould not be used within flammable or explosive

applications. In hazardous applications, use redundant measurement

and control points, each having a different sensing technology. Refer to

the National Electric Code (NEC) for all applicable installation require-

ments in hazardous locations.

Through Wall Installation:

OMEGAENGINEERING’s LVH-200 series sensors may be installed

through the side wall of a tank. The LVH-200 series has dual male

1/2" NPT threads for installation from the outside of the tank in or the

inside of the tank out. If the LVH-200 series is installed in the

Outside-In method, then the outer threads may be used for connection

WARNING

Orientation of the switch is critical. Make sure the switch is

positioned correctly.

Avoid installing the LVH-200 series switch in ferromagnetic

tanks. Doing so will activate the internal reed switch.

to conduit.

Maintenance:

The LVH-200 series sensor itself requires no periodic maintenance

except cleaning as required. It is the responsibility of the user to deter-

mine the appropriate maintenance schedule, based on the specific

characteristics of the application liquids.

Cleaning Procedure:

1. Power: Make Sure that all power to the sensor, controller and/or

power supply is completely disconnected.

2. Sensor Removal: In all through-wall installations, make sure

that the tank is drained well below the sensor prior to removal.

Carefully, remove the sensor from the installation.

3. Cleaning the Sensor: Use a soft bristle brush and mild deter-

gent, carefully wash the LVH-200 series sensor. Do not use harsh

abrasives such as steel wool or sandpaper, which might damage

the surface sensor. Do not use incompatible solvents which may

damage the sensor's Polypropylene plastic body.

4. Sensor Installation: Follow the appropriate steps of installa-

tion as outlined in the installation section of this manual.

Step Four Step Five

ELECTRICAL WIRING

Signal Outputs (Reed Switch):

Normally Open Operation: Orientate the switch such that float swings

down when the switch is dry. In the dry state, the float rests in the

lowest position and the circuit is open.

As the switch becomes wet, the float becomes buoyant and circuit

closes.

Normally Closed Operation: Orientate the switch such that float rests

on top of the switch when the switch is dry. In the dry state, the float

rests on the switch and the circuit is closed.

As the switch becomes wet, the float becomes buoyant and circuit

opens.

Contact Protection (Reed Switch):

When current is interrupted, the inductance of the load generates a

high frequency voltage, which appears across the switch contacts. If

the voltage is large enough, it can cause arcing. Arcing can cause the

contacts to weld to each other resulting in unreliable switching per-

formance. It is essential to protect the circuit, by suppressing the volt-

age to prevent arcing.

This can be accomplished through the use of a diode for DC circuits

and a resistor-capacitor network for AC circuits.

DC Contact Protection:

AC Contact Protection:

Wiring to a OMEGA ENGINEERING Controller:

OMEGA ENGINEERING controllers have a built-in 13.5 VDC

power supply which provides power to all of OMEGA

ENGINEERING's level switches. Alternative controllers and power

supplies may also be used with the LVH-200 series switch.

LVCN-100 Series Controller

LVCN-120/-130/-140 Series Controller

Note: The above wiring is for NO operation. For NC operation, rotate

the switch 180 degrees.

Power

Supply

(+)

(-)

INVERT +/-

IN

P

U

T 1

DELAY

AC

AC

GND

NC

C

NO

R

P

115 VAC

220 VAC

+

RELAY 1 RELAY 2

POWER

INVERT INVERT DELAY

--

+

--

DELAY

INPUT1 INPUT2A INPUT2B

ONOFF

LA

TCH

Power

Supply

Inductive Load

1N4004

Pos

Neg

Inductive Load

100Ω

1/4 watt

.1 F

.600 V

HOT

NTRL

Power

Supply

Power

Supply