9

III.) Getting Started

IMPORTANT: Proper initial installation of equipment

will assure more satisfactory performance, longer

service life, and lower maintenance cost.

Make sure the water heater is on a level surface and in a

protected area where it is not readily influenced by

outside forces such as freezing temperatures, strong

winds, rain, etc. Locate the water heater for easy access

to fill fluids and make adjustments. It is recommended

that a partition is made between the wash area and the

water heater to prevent direct nozzle spray from coming

in contact with the water heater. Excessive moisture will

reduce the water heater’s service life.

TM

IV.) Venting

DANGER: Do not run machine indoors or in an

enclosed area without adequate ventilation, or in

areas where flammable vapors, (gasoline, solvents,

etc.) may be present. Do not vent exhaust gases into

a wall, a ceiling, or a concealed space.

CAUTION: All venting must be in accordance with

applicable federal and state laws, and local

ordinances. Consult local heating contractors.

If the water heater is to be used in an enclosed area, a

flue must be installed to vent burner exhaust to the

outside atmosphere. Be sure the flue is the same size

as the burner exhaust vent on the water heater lid. Poor

draft will cause the water heater to soot and not operate

properly. When selecting the location for installation,

beware of poorly ventilated locations or areas where

exhaust fans may cause an insufficient supply of

oxygen. Proper combustion can only be obtained when

there is a sufficient supply of oxygen available for the

amount of fuel being burned. If it is necessary to install

a unit in a poorly ventilated area, outside fresh air may

have to be piped to the burner and a fan installed to

bring sufficient air into the unit. Locate the water heater

in such a manner that the flue will be as straight as

possible and protrude through the roof at a proper height

and location to provide adequate draft. This oil fired unit

must have a draft controller installed in the flue (Part

#18007 call 1-800-270-0810 to order). A draft controller

will permit proper upward airflow of exhaust flue gases.

V.) Oil Burner

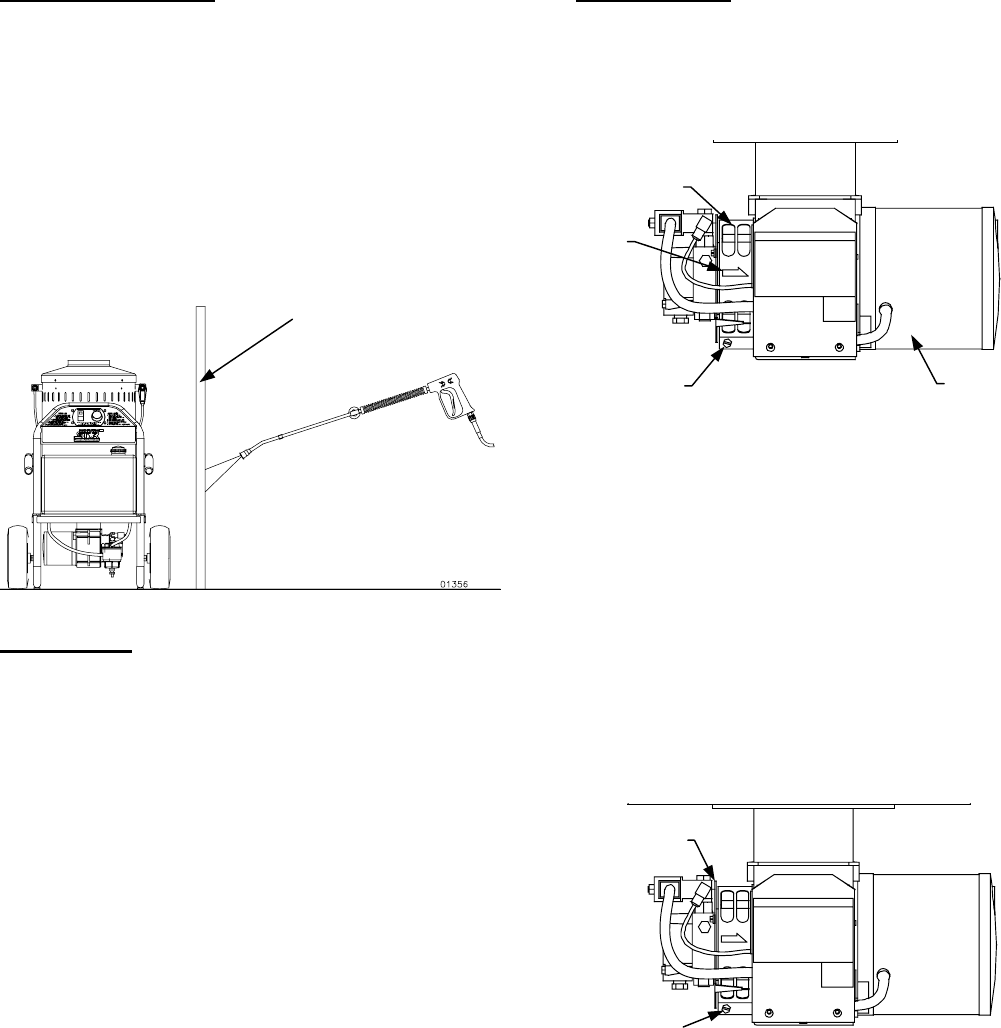

Burner Air Adjustment: The oil burner is preset and

performance tested at the factory (elevation 1100 feet).

A one-time initial correction of the burner for your

location will pay off in economy, performance, and

extended service life.

1.) Turn the pump and heat switches on (Refer to

“Operation” for details). Have someone operate the

spray gun so the burner fires.

2.) Loosen the locking screw and close the air band

until black smoke appears from the burner exhaust

vent. Note the position of the white arrow on the air

band.

3.) Slowly open the air band until white smoke just

starts to appear.

4.) Turn the air band half way back to the black smoke

position previously noted. Tighten the locking

screw.

5.) Fine tune the burner air by loosening the shutter lock

screw and turning the shutter until the exhaust is

cleanest. Tighten the shutter lock screw.

CAUTION: If white smoke appears from the burner

exhaust vent during start-up or operation,

discontinue use and readjust air bands.

NOTE: If a flue is installed, have a professional

serviceman adjust your burner for a #1 or #2 smoke

spot on the Bacharach scale.

Locking

Screw

A

ir Band

Burner

White

Arrow

Shutte

r

Lock Screw

Shutte

r

Partition