20

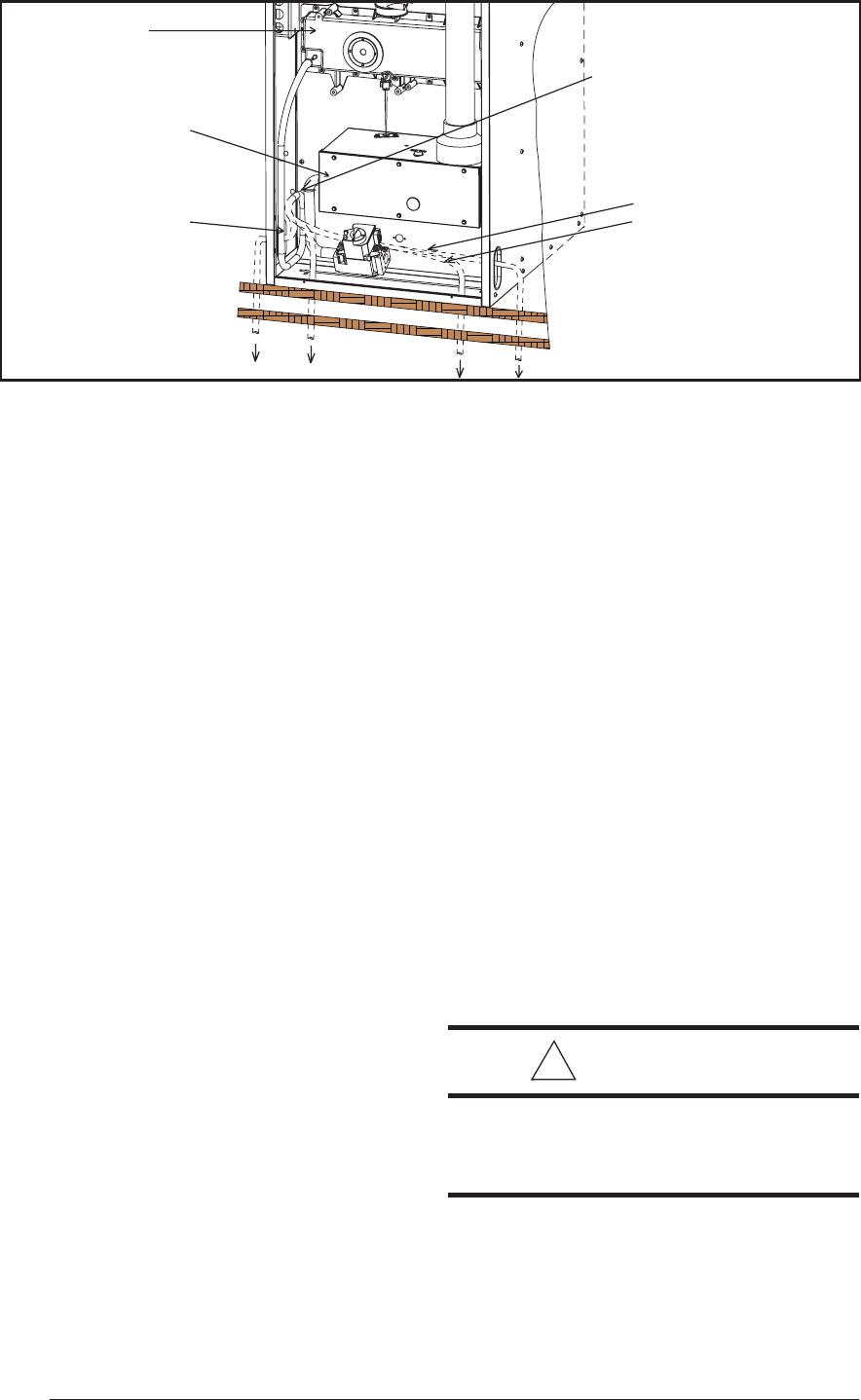

Figure 21. Furnace with Condensate Drain Trap Assembly

A

A

Clamp

Step 1: Loosen

Step 2: Rotate to drain direction

Step 3: Retighten

Keep

Downward

Slope

Alt. Drain

Alt. Drain

Alt. Drain

Alt. Drain

Floor Cavity

Floor

“Hard”

J Drain Tube

Burner

Box

Collector

Box

1. Remove the collector box soft tube at

location A in Figure 21 and insure the exit

from the collector box is clear of any

debris or obstructions.

2. Replace this tube and insure the fit to the

header spout is air tight. Air will be drawn into

the header if this connection is not tight.

3. Check other tube connections along the

drain system. Insure that all are air tight.

NOTE: Industry research studies indicate that

when condensate is routed to an active drain,

household detergents, etc., buffer its acidity. If

the drain is not actively used or if codes require,

obtain a neutralizer kit (See Table 12). Proper

drains and connections to the condensate tub-

ing are required as NORDYNE cannot be held

responsible for water leakage which occurs

due to loose hose connections or improperly

sealed drain line pipes.

GAS SUPPLY AND PIPING

General

This furnace is equipped for bottom, left, or

right side gas entry. Typical gas service hook-

ups are shown in Figure 22. When making the

gas connection provide clearance between the

gas supply line and the entry hole in the furnace

casing to avoid unwanted noise and/or damage

to the furnace.

All gas piping must be installed in compliance

with local codes and utility regulations. Some

local regulations require the installation of a manual

main shut-off valve and ground joint union exter-

nal to the furnace. The shut-off valve should be

readily accessible for service and/or emer-

gency use. Consult the local utility or gas

supplier for additional requirements regarding

placement of the manual main gas shut-off. In

the absence of local codes, the gas line instal-

lation must comply with the provisions stated in

the Federal Manufactured Home Standard

(H.U.D Title 24, part 280) and the National Fuel

Gas Code (ANSI Z223.1/NFPA-54) or (CAN/

CGA B149) installation codes.

A drip leg should be installed in the vertical pipe

run to the unit. Table 7 lists gas flow capacities

for standard pipe sizes as a function of length

in typical applications based on nominal pres-

sure drop in the line.

NOTE: Gas piping must not be run in or through

air ducts, gas vents, etc.

Compounds used on threaded joints of gas

piping must be resistant to the actions of lique-

fied petroleum gases.

!

CAUTION:

Do not use matches, lighters, candles,

or other sources of open flame to check

for gas leaks.

NOTE: When pressure testing gas supply

lines at pressures greater than 1/2 psig (14 in.

water column), the furnace must be discon-

nected from the gas supply piping system to

prevent damage to the gas control valve.