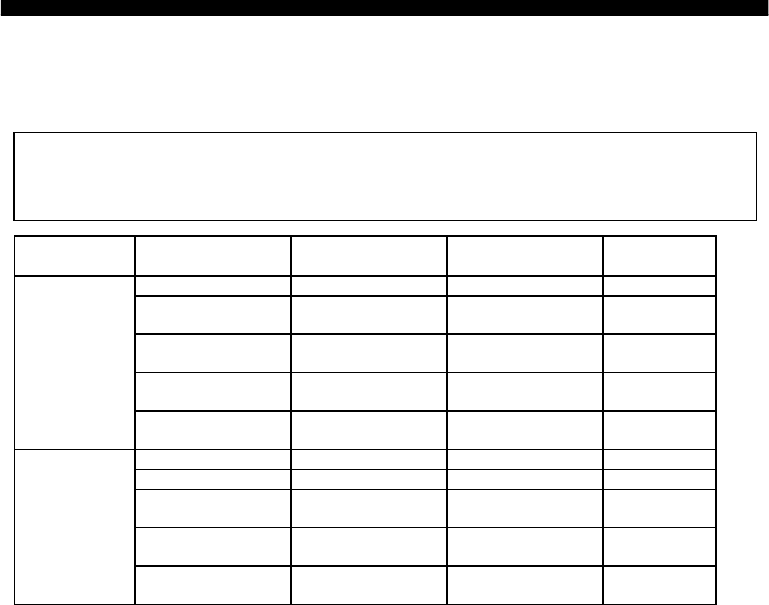

4 Maintenance and inspection schedule

If the boat does not accumulate the hours indicated below within 3 months, the frequency

is every 3:rd month.

Warning !

Failure to rectify any faulty conditions discovered as a result of the inspection could cause

sudden loss of Autopilot control, with consequential danger. It is recommended that all

items referenced in the following table be inspected before commencing any cruise.

Type Equipment: Check for: Remedy: Inspection

Frequency:

Hydraulic Oil reservoir level Correct Fill 200 hrs

Oil condition Discoloration

Contamination

Flush system and

replace the oil

1000 hrs

1000 hrs

Hydraulic hoses Damage

Leaks & Corrosion

Replace 1000 hrs

Hydraulic fittings Damage

Leaks & Loosening

Replace

Tighten

500 hrs

Piston rod seals

on pumpset

Leaking Replace 1000 hrs

Mechanical Linear drive Corrosion Replace or Repair 2000 hrs

Tiller arm Corrosion Replace 2000 hrs

Tiller bolts Corrosion

Loosening

Replace

Tighten

2000 hrs

500 hrs

Rod end bolt

on linear drive

Corrosion

Loosening

Replace

Tighten

2000 hrs

500 hrs

Trunnion bolts

on linear drive

Corrosion

Loosening

Replace

Tighten

2000 hrs

500 hrs

5 Specifications

Type of Pumpset: Reversible axial piston pump, 5-cylinder

Dimensions: Length 230 x width 105 x height 100 mm (91 x 41 x 40”)

Weight PF-0,3 (without oil): 3 kg (6.60 lb)

Weight PF-0,3S (without oil): 3,3 kg (7.27 lb)

Enclosure: Splash proof

Temperature range: -5° to +50° C (+40° to 122° F)

Power supply: Both Pumpsets available in 12 or 24 V DC

Peak pressure: 70 bar (1000PSI)

Ram capacity min - max: 100 - 400 cc (6 - 24 in3) (no load)

Peak flow rate: 1150 cc/min (70 in3/min) (no load)

Average power consumption: 2 - 4 A ca 36 Watts (at 12V)

Piping pressure: 1000 PSI (70bar)

Piping size: Min. 8 mm (0.32”) inner diameter

Port dimensions: ¼" NPT

Hydraulic oil viscosity: ISO 20

Warranty period: 2 years, see separate conditions

CE approval: The product conforms to the EMC requirements for immunity and emission

according to EN 5008-1 and EN 55022

INSTALLATION