PAGE 14 — QP402H CENTRIFUGAL PUMP • OPERATION AND PARTS MANUAL — REV. #2 (01/29/14)

PUMP COMPONENTS

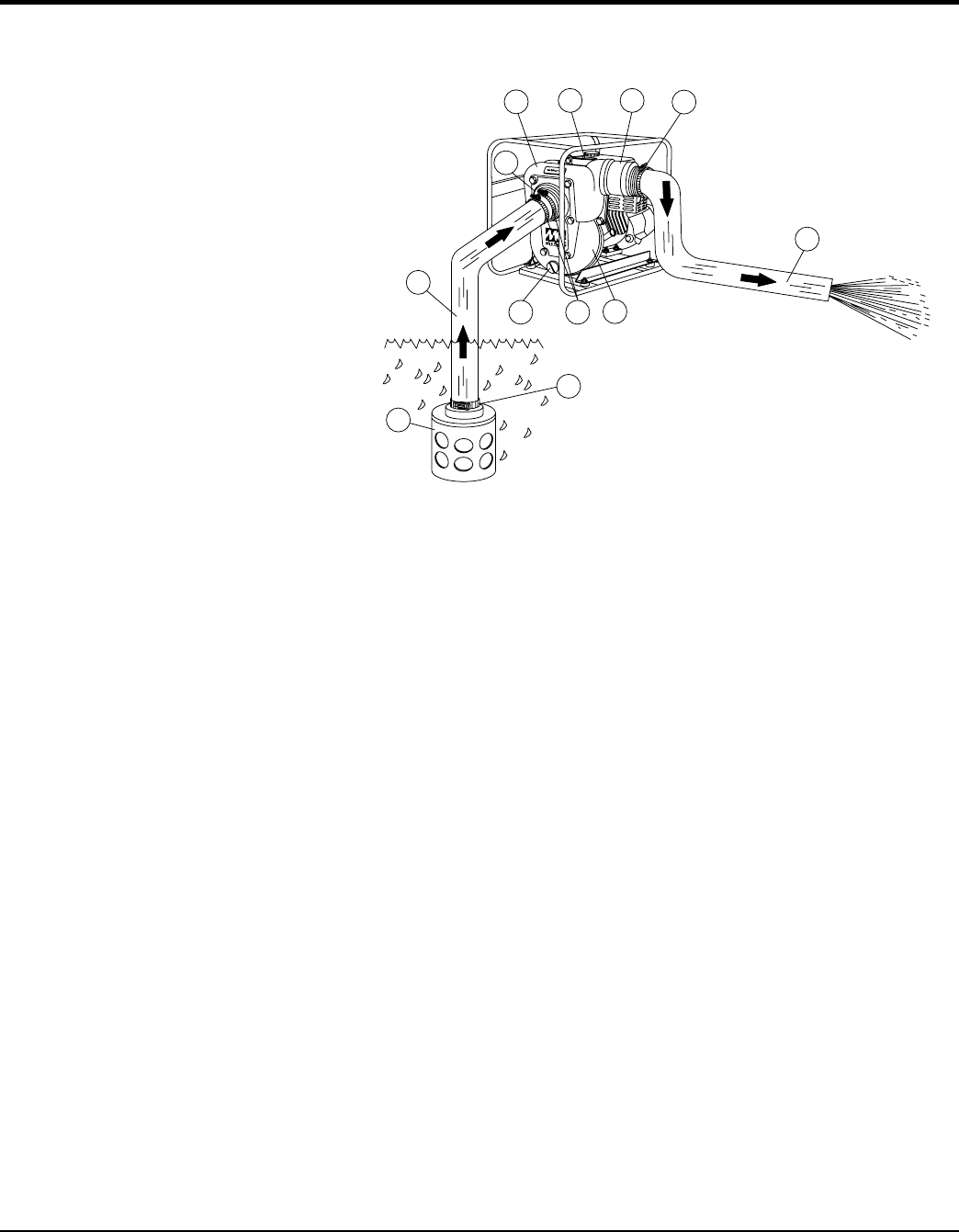

Figure 3 shows a typical application using the QP402H centrifugal pump. Please note that this pump is intended for the

removal of clean water. .

7

4

9

5

8

2

4

1

3

6

6

4

Figure 3. QP402H Pump Application

1. Pump — The QP402H is a 4-inch centrifugal pump

used in general de-watering applications.

2. Fill Cap — Prior to operation, the pump casing should

be filled with water. Remove this cap to add water to

the pump. After the initial prime, a sufficient amount of

water will be retained in the casing so that the operator

will not need to re-prime later.

If the casing is dry or has insufficient water, the pump

will have difficulty in priming which could lead to

premature mechanical seal wear thus causing damage

to the pump.

3. Discharge Port — Connect a 4-inch discharge hose

to this port.

4. Worm Clamp — Used to secure the hose to the inlet

and outlet ports on the pump. Use two clamps to secure

the hose on the inlet side of the pump.

5. Discharge Hose — Connect this flexible rubber

hose to the discharge port on the pump. Make sure

that the hose lays flat and is not kinked. Use only

recommended type discharge hose. Contact Multiquip

parts department for ordering information.

6. Suction Port — Connect a 4-inch inlet hose to this

port. Use two worm clamps to secure the hose.

7. Suction Hose — Connect this flexible rubber hose to

the suction port on the pump. Make sure that the hose

lays flat and is not kinked. Use only recommended type

suction hose. Contact Multiquip parts department for

ordering information.

8. Drain Plug — Remove this plug to drain water from

the pump.

9. Strainer — Always attach a strainer to bottom side of

the suction hose to prevent large objects and debris

from entering the pump. Strainer should be positioned

so that it will remain completely under water. Running

the pump with the strainer above water for long periods

can damage pump.