© COPYRIGHT 2005, MULTIQUIP INC.

Montreal, Canada • Manchester, UK

Rio De Janeiro, Brazil • Cipsa, Mexico

MULTIQUIP INC.

POST OFFICE BOX 6254 • CARSON, CA 90749

310-537-3700 • 800-421-1244 • FAX: 310-537-3927

E-MAIL: mq@multiquip.com • WWW: multiquip.com

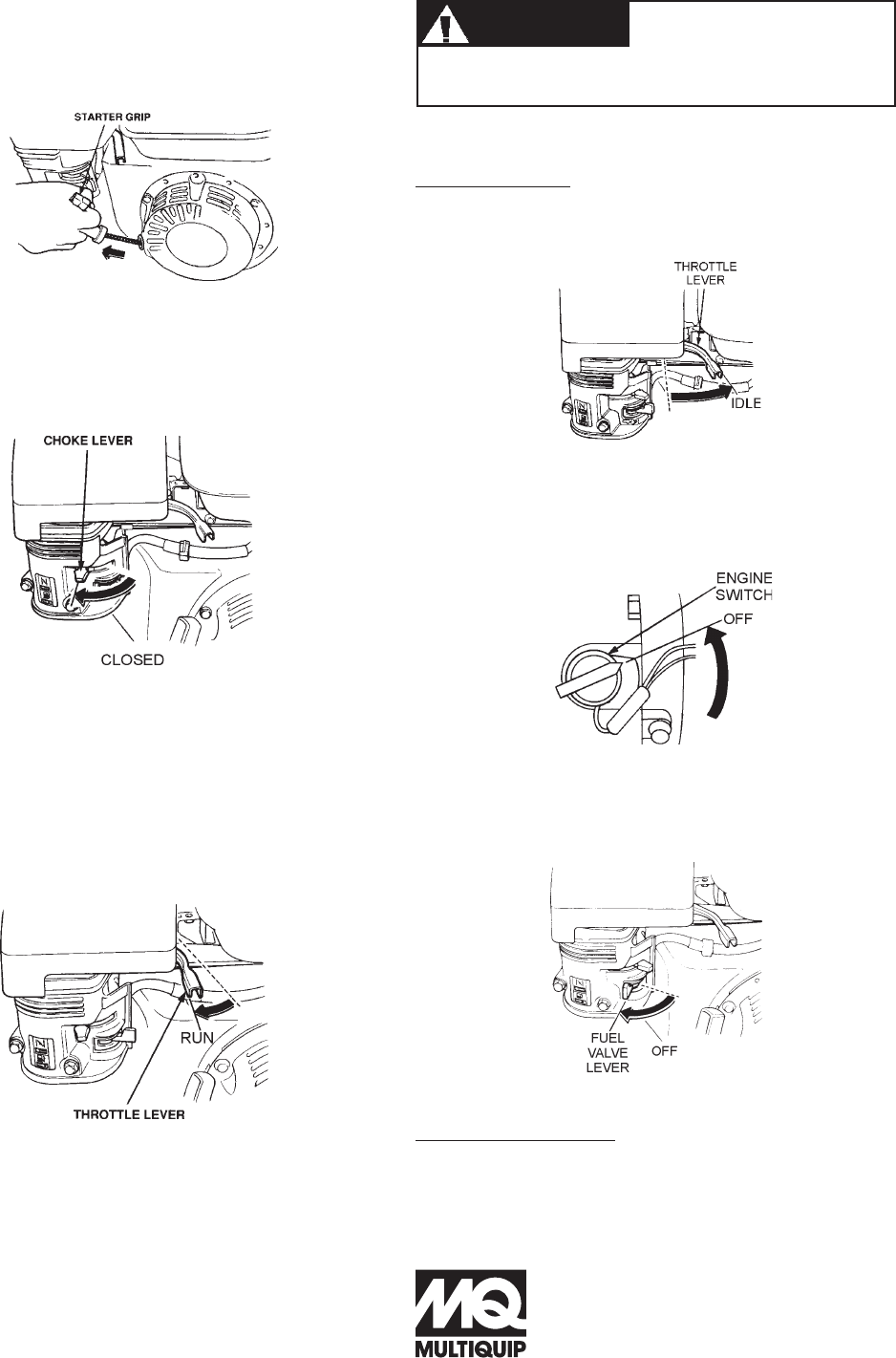

6. Grasp the starter grip (Figure 6) and slowly pull it out. The

resistance becomes the hardest at a certain position, corre-

sponding to the compression point. Pull the starter grip

briskly and smoothly for starting.

7. If the engine has started, slowly return the choke lever

(Figure 7) to the

CLOSED

position. If the engine has not

started repeat steps 1 through 6.

Figure 6. Starter Grip

8. Before the pump is placed into operation, run the engine for

several minutes. Check for fuel leaks, and noises that would

associate with a lose component.

9. To begin pumping, place the throttle lever (Figure 8) in the

"

RUN

"position.

Figure 7. Choke Lever (Closed)

Figure 8. Throttle Lever (Run)

Stopping The Engine

Normal Shutdown

1. Move the throttle lever to the IDLE position (Figure 9) and

run the engine for three minutes at low speed.

Figure 9. Throttle Lever (Idle)

2. After the engine

cools

, turn the engine ON/OFF switch to the

“OFF” position (Figure 10).

3. Place the

fuel shut-off lever

(Figure 11) in the OFF

position.

Figure 10. Engine ON/OFF Switch (OFF)

Figure 11. Fuel Valve Lever (OFF)

Emergency Showdown

1. Move the throttle lever quickly to the

IDLE

position, and place

the engine ON/OFF switch in the

OFF

position.

ALWAYS run engine at

full speed

while pumping.

CAUTIONCAUTION

CAUTIONCAUTION

CAUTION