DRY PRIME PUMP — OPERATION AND PARTS MANUAL — REV. #3 (10/06/08) — PAGE 31

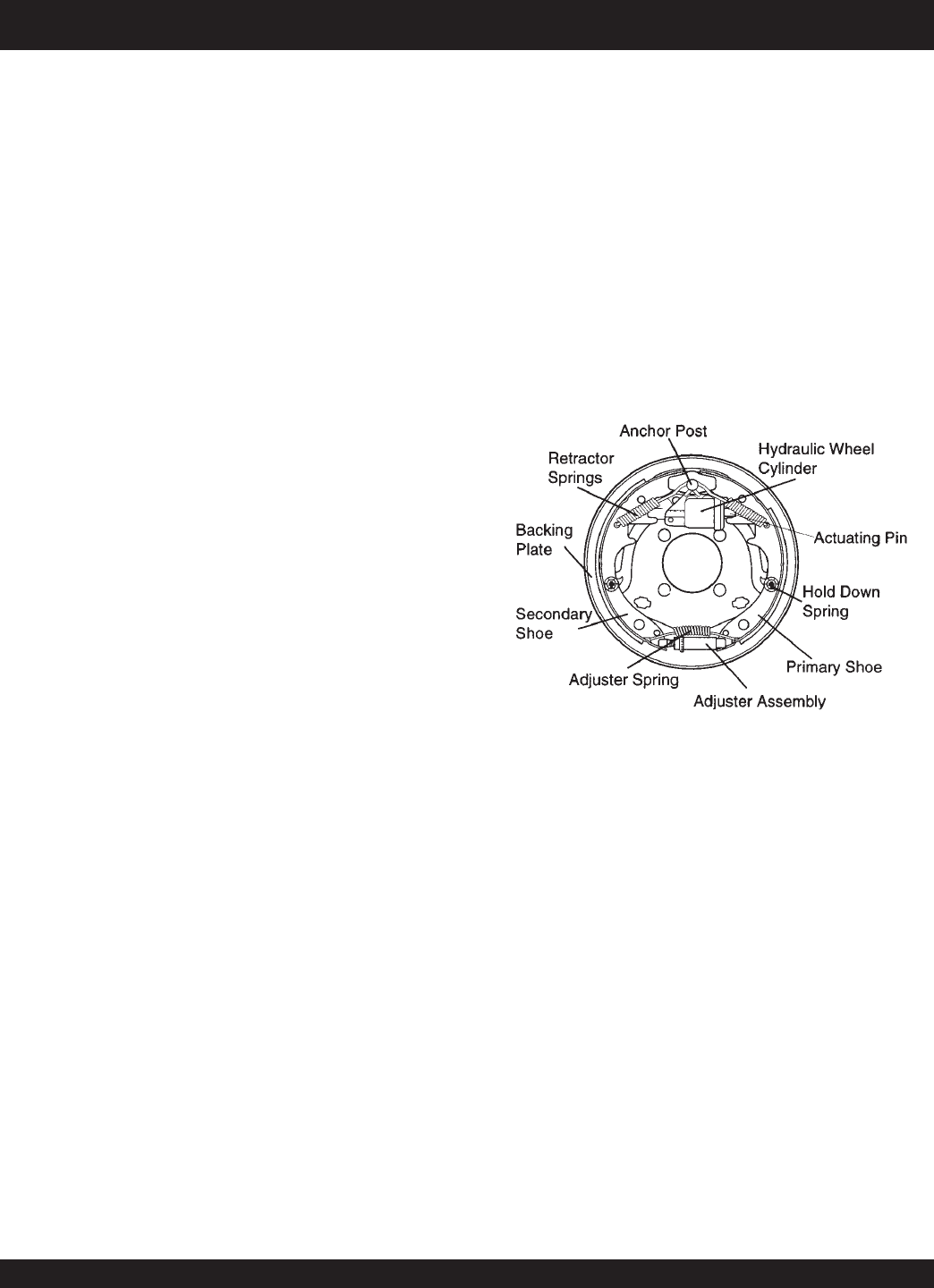

Figure 19. Surge Brake Components

You must check the fluid level in the master cylinder

reservoir at least every three months. If you tow your trailer

an average of 1,000 miles per month in a hot and dry

environment, you must check the brake fluid level once a

month. The brake fluid reservoir is located on the tongue of

the trailer. Always fill with clean, uncontaminated DOT 4

brake fluid.

Figure 19 below displays the major air/surge brake compo-

nents that will require inspection and maintenance. Please

inspect these components as required using steps 1 through

6 as referenced in the “Manually Adjusting The Brakes” sec-

tion on this page. See Table 11 Surge Brake Troubleshoot-

ing.

Electric Brakes

Electrically actuated brakes (Figure 20) are similar to

surge brakes. The basic difference is that surge brakes are

actuated by an electromagnet. Listed below are some of

the advantages that electric brakes have over

surge brakes:

Brake system can be manually adjusted to provide the

corrected braking capability for varying road and load

conditions.

Brake system can be modulated to provide more or

less braking force, thus easing the brake load on the

towing vehicle.

Brake system has very little lag time between the time

the vehicle’s brakes are actuated and the trailer’s brakes

are actuated.

Brake system can provide an independent emergency

brake system.

Trailer Brakes

Properly functioning brake shoes and drums are essential to

ensure safety. The brakes should be inspected the first 200

miles of operation. This will allow the brake shoes and drums

to seat properly. After the first 200 mile interval, inspect the

brakes every 3,000 miles. If driving over rough terrain, in-

spect the brakes more frequently.

Surge Brakes

If your trailer has surge-operated brakes, they

function the same way the surge brakes do on your tow

vehicle. The surge braking system must be inspected at

least as often as the brakes on the tow vehicle, but no less

than once per year. This inspection includes an

assessment of the condition and proper operation of the wheel

cylinders, brake shoes, brake drums and hubs.

Manually Adjusting the Brakes

Most axles are fitted with a brake mechanism that will

adjust the brakes during a hard stop. However, some

braking systems are not automatically adjusted by hard

stopping. These brakes require manual adjustment. The

following steps apply to adjust most manually adjustable

brakes.

1. Jack up the trailer and secure it on adequate capacity

jack stands.

2. Be sure the wheel and brake drum rotate freely.

3. Remove the adjusting-hole cover from the adjusting slot

on the bottom of the brake backing plate.

4. With a screwdriver or standard adjusting tool, rotate the

starwheel of the adjuster assembly to expand the brake

shoes. Adjust the brake shoes out until the pressure of

the linings against the drum makes the wheel very

difficult to turn. Note: Your trailer maybe equipped with

drop spindle axles. See axle manual for your axle type.

You will need a modified adjusting tool for adjusting the

brakes in these axles. With drop spindle axles, a

modified adjusting tool with about an 80 degree angle

should be used.

5. Rotate the starwheel in the opposite direction until the

wheel turns freely with a slight drag.

6. Replace the adjusting-hole cover.

7. Repeat the above procedure on all brakes.

8. Lower the trailer to the ground.

MAINTENANCE (TRAILER)

The following trailer maintenance guidelines are intended to

assist the operator in preventative maintenance.