JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 11

JIMMY SERIES HYDRAULIC REBAR BENDERS — GENERAL INFORMATION

GENERAL INFORMATION

The

MQ Jimmy Series Hydraulic Rebar Benders

are designed

to be used as

portable

on-site rebar benders, capable of bending

in-place rebar to approved American Concrete Institute (ACI) radius.

Labor time and injuries are greatly reduced from manually bending

rebar. Bends of 90°, 135° or 180° can now be completed in seconds

at the correct elevation after forms are stripped away.

With seven models to choose from, the Jimmy Series rebar benders

can accommodate a wide variety of rebar angles and sizes. Please

reference Tables 1 and 2 in this manual for the rebar bender that

best fits your application.

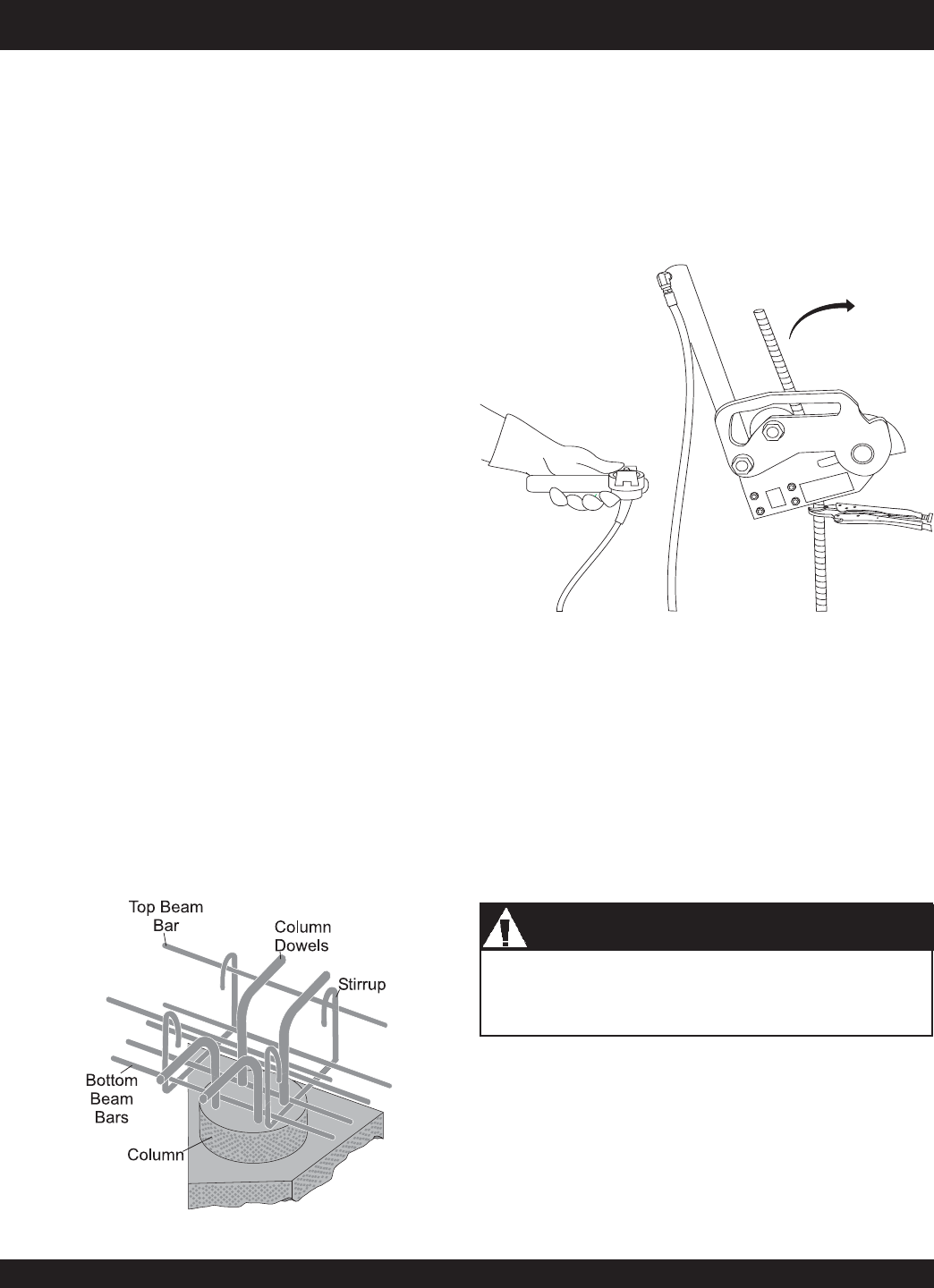

REBAR BENDING APPLICATIONS (Figures 1 thru 4)

■

Pilings

■

Caissons

■

Bridge and Decking

■

Retrofits

■

Columns

■

Straightening

■

Walls

Rebar Columns

■

90° rebar (Figure 1) at top of column can be bent after forms

have been removed

■

Bending after concrete is poured allows you to stock bottom

beam bars, eliminating the need to thread bottom beam bars.

■

Rebar at top of column can be bent at exactly the correct

elevation allowing top beam bars to placed on top of 90°

bend.

Figure 1. Columns

Rebar Straightening

■

Rebar can be straightened using JB5090, JB7090, JB8090,

JB9180 and JB11090.

■

NEVER straighten rebar that is bent greater than 30°. Check

with building codes before straightening rebar

Figure 2. Rebar Straightening

■

Before the rebar can be straightened by the JB5090, JB7090

or JB8090, it will be necessary to replace the main roller with

the straightening roller. The straightening roller is included

with each of the above models from the factory. To accomplish

this task remove the main shaft as outlined in Figure 14.

Some agencies may not permit the straightening of rebar

for existing bends of more than 30°. DO NOT attempt to

straighten rebar bends greater than 30°.

CAUTION

CAUTIONCAUTION

CAUTIONCAUTION

CAUTION