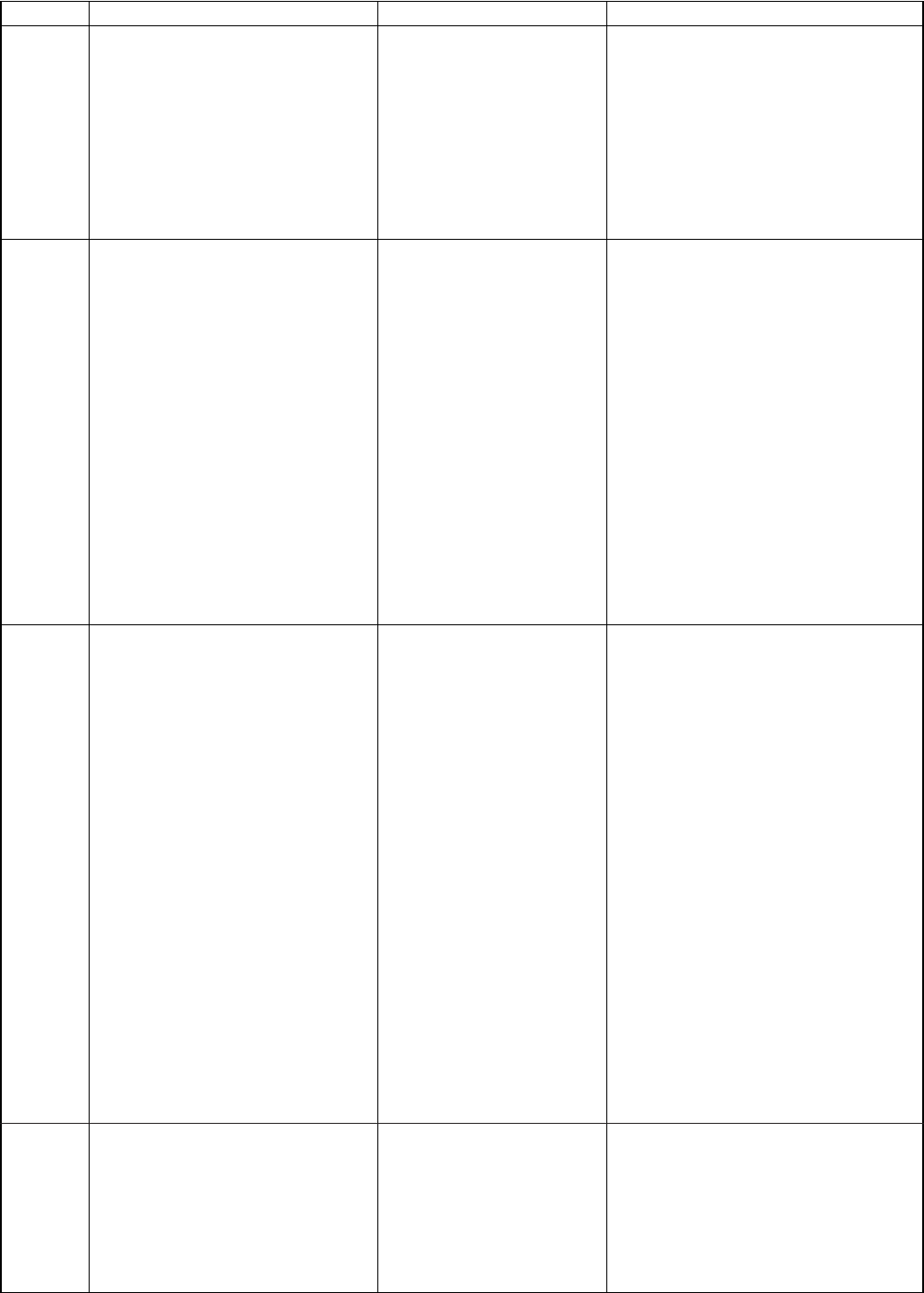

40

Error Code

Abnormal point and detection method

Judgment and action

UL

(1300)

Low pressure (63L worked)

Abnormal if 63L is worked (under-

0.03MPa) during compressor operation.

63L: Low-pressure switch

(A42N only)

1 Stop valve of outdoor unit is

closed during operation.

2 Disconnection or loose connection

of connector (63L) on outdoor

controller board

3 Disconnection or loose

connection of 63L

4 Defective outdoor controller board

5 Leakage or shortage of refrigerant

6 Malfunction of linear expansion

valve

1 Check stop valve.

2~4 Turn the power off and on again to check

if F3 is displayed on restarting.

If F3 is displayed, follow the F3 processing

direction.

5 Correct to proper amount of refrigerant.

6 Check linear expansion valve.

Refer to 10-6.

Case

UP

(4210)

Compressor overcurrent interruption

Abnormal if overcurrent DC bus or com-

pressor is detected after compressor starts

operating for 30 seconds.

1 Stop valve of outdoor unit is

closed.

2 Decrease of power supply volt-

age

3 Looseness, disconnection or

converse of compressor wiring

connection

4 Defective fan of indoor/outdoor

units

5 Short cycle of indoor/outdoor

units

6 Defective input circuit of out-

door controller board

7 Defective compressor

1 Open stop valve.

2 Check facility of power supply.

3 Correct the wiring (U·V·W phase) to

compressor. Refer to 10-9 (Outdoor power

circuit board).

4 Check indoor/outdoor fan.

5 Solve short cycle.

6 Replace outdoor controller circuit board.

7 Check compressor.

Refer to 10-6.

W Before the replacement of the outdoor

controller circuit board, disconnect the wiring

to compressor from the outdoor power circuit

board and check the output voltage among

phases, U, V, W, during test run. No defect

on board if voltage among phases (U-V, V-W

and W-U) is same. Make sure to perform the

voltage check with same performing frequency.

E0

or

E4

Remote controller transmission

error(E0)/signal receiving error(E4)

1 Abnormal if main or sub remote con-

troller cannot receive normally any trans-

mission from indoor unit of refrigerant

address “0” for 3 minutes.

(Error code : E0)

2 Abnormal if sub-remote controller could

not receive for any signal for 2 minutes.

(Error code: E0)

1 Abnormal if indoor controller board can

not receive any data normally from

remote controller board or from other

indoor controller board for 3 minutes.

(Error code: E4)

2 Indoor controller board cannot receive

any signal from remote controller for 2

minutes. (Error code: E4)

1 Check disconnection or looseness of indoor

unit or transmission wire of remote controller.

2 Set one of the remote controllers “main”.

If there is no problem with the action above.

3 Check wiring of remote controller.

• Total wiring length: max. 500m[1640ft]

(Do not use cable o 3 or more.)

• The number of connecting indoor units:

max. 16 units

• The number of connecting remote con-

troller: max. 2 units

When the above-mentioned problem of 1~3

are not applied

4 Diagnose remote controllers.

a) When “RC OK” is displayed,

remote controllers have no problem.

Turn the power off, and on again to

check. If abnormality generates again,

replace indoor controller board.

b) When “RC NG” is displayed,

replace remote controller.

c) When “RC E3” is displayed,

d) When “ERC 00-06” is displayed,

[ c),d)→Noise may be causing abnormality. ]

∗ If the unit is not normal after replacing

indoor controller board in group control,

indoor controller board of address “0”

may be abnormal.

1 Contact failure at transmission

wire of remote controller

2 All remote controllers are set

as “sub” remote controller. In

this case, E0 is displayed on

remote controller, and E4 is

displayed at LED (LED1, LED2)

on the outdoor controller circuit

board.

3 Miswiring of remote controller

4 Defective transmitting receiving

circuit of remote controller

5 Defective transmitting receiving

circuit of indoor controller board

of refrigerant address “0”.

6 Noise has entered into the

transmission wire of remote

controller.

E1

or

E2

Remote controller control board

1 Abnormal if data cannot be normally

read from the nonvolatile memory of the

remote controller control board.

(Error code: E1)

2 Abnormal if the clock function of remote

controller cannot be normally operated.

(Error code: E2)

1 Defective remote controller 1 Replace remote controller.

OCH429--2.qxp 07.11.20 9:18 AM Page 40