HVAC Advanced Products Division

Mitsubishi Electric & Electronics USA, Inc.

3400 Lawrenceville Suwanee Rd.

Suwanee, GA 30024

Tele: 678-376-2900 • Fax: 800-889-9904

Toll Free: 800-433-4822 (#4)

www.mehvac.com

Specications are subject to change without notice.

C SD - PUHY-P168TSHMU-A - 1 - 200809 © MITSUBISHI ELECTRIC / HVAC 2008

Certificate Number FM33568

Certificate Number EC97J1227

Mitsubishi Electric Air Conditioning & Refrigeration Systems Works acquired ISO

9001 certification under Series 9000 of the International Standard Organization (ISO)

based on a review of quality warranties for the production of refrigeration and air

conditioning equipment.

ISO Authorization System

The ISO 9000 series is a plant authorization system relating to quality warranties as

stipulated by the ISO. ISO 9001 certifies quality warranties based on the "design,

development, production, installation and auxiliary services" for products built at

an authorized plant.

Mitsubishi Electric Air Conditioning & Refrigeration Systems Works acquired environmental

management system standard ISO 14001 certification.

The ISO 14000 series is a set of standards applying to environmental protection set by the

International Standard Organization (ISO).

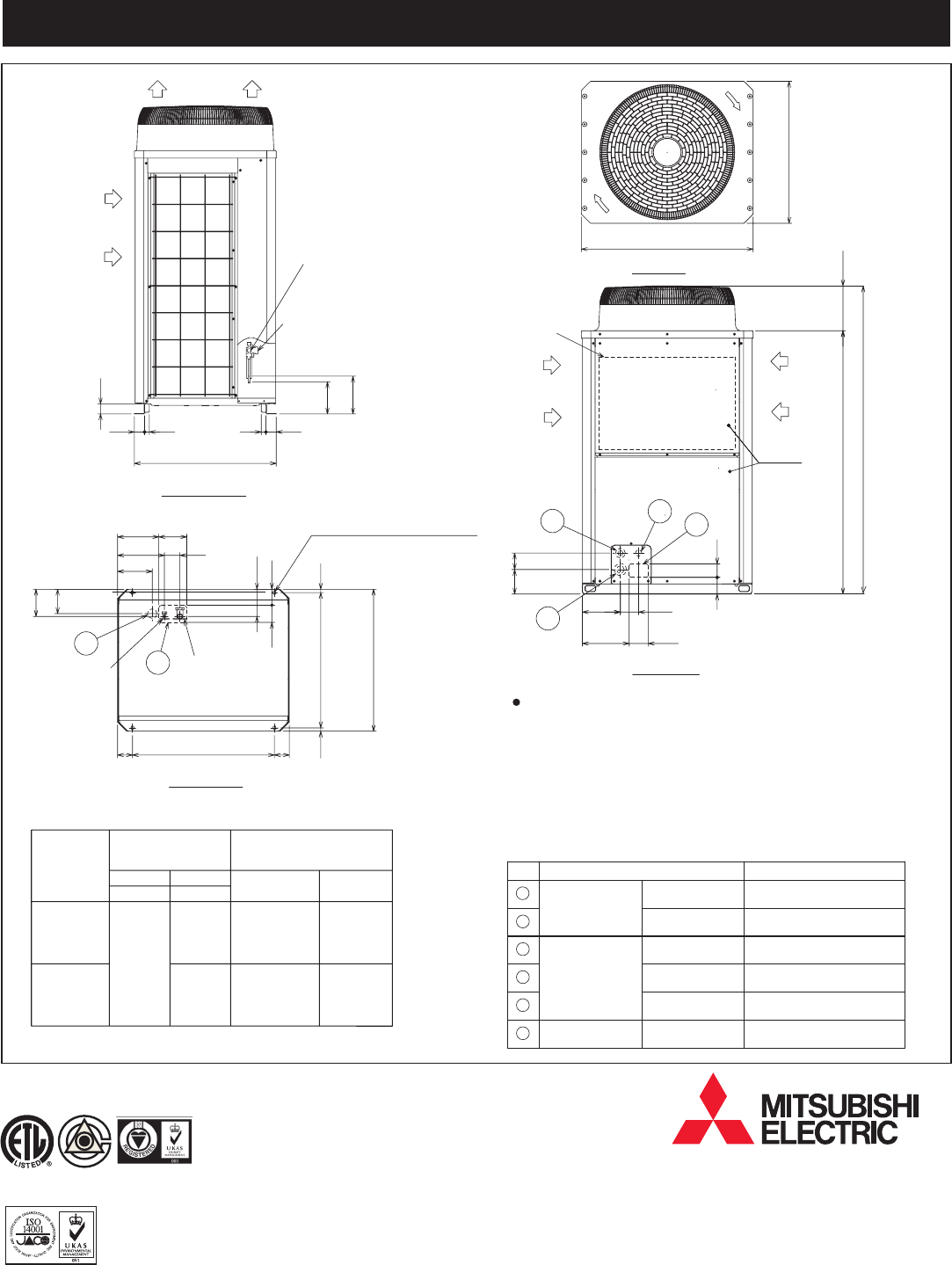

Modules 1 and 2: PUHY-P96THMU-A and PUHY-P72THMU-A – DIMENSIONS

Refrigerant service

valve <gas>

Refrigerant service

valve <liquid>

Accessories

Connecting pipe

Gas · Elbow (IDø25.4 [1] X ODø25.4 [1])·············P72, P96 1 pc.

· Pipe (IDø25.4 [1] X ODø19.05 [3/4])········P72 1 pc.

· Pipe (IDø25.4 [1] X ODø22.2 [7/8])··········P96 1 pc.

Liquid ·

Pipe (IDø9.52 [3/8] X ODø9.52 [3/8])·······P72, P96 1 pc.

Front access hole

Bottom access hole

Front access hole

Front access hole

Specifications

Usage

NO.

Front access hole

102 X 72 Knockout hole

150 X 92 Knockout hole

Bottom access hole

ø62.7 or ø34.5 Knockout hole

For pipes

For wires

ø43.7 or ø22.2 Knockout hole

ø52 Knockout hole

For transmission cables

ø34 Knockout hole

(29-15/16)

(2-3/16) (1) (1)(2-3/16)

(2-5/32)

(5-7/32) (3-15/32)

(9-29/32)

(8-1/16)

(4-1/32)

(3-7/8)

(3-9/16)

(2-27/32)

(55-17/32)

(64-31/32)

(9-15/32)

(36-1/4)

(29-15/16)

760

5555

A

B

72

Control box

132

6

4

3

1

25

Intake

air

90

204

102251

240

Intake

air

Service

panel

1410

1650

760

920

88

25

54

Intake

air

Discharge air

98

(7/8)

(1-11/32)

(2-1/16)

(1-3/4)

(1-3/8)

(2-15/32)

(3-5/8)(5-29/32)

(2-27/32)(4-1/32)

Front view

Left side view

Top view

(Mounting pitch)

(Mounting pitch)

Refrigerant service

valve <gas>

Refrigerant service

valve <liquid>

(28-17/32)

(5-23/32)

(3-5/8)

(3-13/32)

(3-9/32)

(5-29/32)

(7-11/32)

(8-23/32)

(9-29/32)

(5-3/16)

(5-23/32)

(3-5/32)

(29-15/16)

(3-5/32)

(23/32)

(28-13/32 ~ 28-5/8)

(29-15/16)

(23/32)

2 X 2-14(9/16) X 20(13/16) Oval hole

221 150

145

83

(760)

80

760

80

18

724(721

~ 727)

18

92

86

131

251

186

5

2

145

Bottom view

Note 1. Refer to the Engineering or Installation manual for information regarding

necessary clearance around the unit, and installation site requirements.

2. When brazing the pipes, protect the refrigerant service valve by wrapping

it with a wet cloth to keep its temperature under 120°C (248°F).

1

2

4

3

5

6

(ø12.7 Brazed)*2

ø9.52 Brazed

ø9.52 Brazed

PUHY-P96THMU

(-BS)

PUHY-P72THMU

(-BS)

ø22.2 Brazed

B

A

ø19.05 Brazed

Gas

Liquid

Gas

Liquid

Connection specifications for

the refrigerant service valve

Position dimensions

for the refrigerant

service valve

Model

Connecting pipe specifications

*1 Use the connecting pipes (for bottom and front pipes) that are supplied.

*2 Total length 90m (295')

*1

(1/2)

(3/8)

(3/8)

142

(5-19/32)

172

(6-25/32)

(3/4)

(7/8)

170

(6-23/32)

>

=

Unit : mm(in)