8

6. Electrical work

S1

S2

S3

L1

L2

GR

BLUE

BLUE

YELLOW

YELLOW

CND

CND

ORANGE

CND

ORANGE

S1

S2

S3

L1

L2

GR

YELLOW

BLUE

BLUE

YELLOW

CND

6.1.2. Separate indoor unit/outdoor unit power supplies (A-control application)

The following connection patterns are available.

The outdoor unit power supply patterns vary on models.

1:1 System

S1

S2

L1

L2

GR

GR

1

2

L1

L2

S1

S2

S3

S3

A

B

C

G

D

B

E

F

* Affix a label B that is included with the manuals near each wiring diagram for the indoor and outdoor units.

A Outdoor unit power supply

B Wiring circuit breaker or isolating switch

C Outdoor unit

D Indoor unit/outdoor unit connecting cords

E Remote controller (Only for PKA-A·FA)

F Indoor unit

G Indoor unit power supply

If the indoor and outdoor units have separate power supplies, refer to the table at the

below. Change the indoor unit electrical box wiring refering to the figure in the right

and the DIP switch settings of the outdoor unit control board.

ON

OFF 1 2

(SW8)

3

Indoor unit electrical box connector con-

nection change

Label affixed near each wiring diagram

for the indoor and outdoor units

Outdoor unit DIP switch settings (when

using separate indoor unit/outdoor unit

power supplies only)

Indoor unit specifications

Required

Required

*1. Max. 50 m, 165 ft

*2. The 10 m, 30 ft wire is attached in the remote controller accessory. Max. 500 m, 1500 ft

*3. The figures are NOT always against the ground.

Notes: 1. Wiring size must comply with the applicable local and national code.

2. Use copper supply wires.

3. Use wires rated 300V or more for the power supply cables.

4. Install an earth longer than other cables.

Indoor unit model

Indoor unit power supply

Minimum circuit ampacity

Maximum rating of overcurrent protective device

Indoor unit power supply

Indoor unit power supply earth

Indoor unit-Outdoor unit *1

Indoor unit earth

Remote controller-Indoor unit *2

Indoor unit L1-L2 *3

Indoor unit-Outdoor unit S1-S2 *3

Indoor unit-Outdoor unit S2-S3 *3

Remote controller-Indoor unit *3

PKA

Single 208/230 V, 60 Hz

1 A

15A

2 × Min. AWG16

1 × Min. AWG16

2 × AWG22 (polar)

–

2 × AWG22 (Non-polar)

AC 208/230 V

–

DC24 V

DC12 V

Circuit

rating

Wiring

Wire No. × size

Connectors (connections when shipped

from the factory are for indoor unit power

supplied from outdoor unit)

Indoor unit power supplied from outdoor unit

(when shipped from factory)

If the indoor and

outdoor units have

separate power

supplies, change the

connections of the

connectors as shown

in the following

figure.

Connectors

Indoor unit

control board

Separate indoor unit/outdoor unit power

supplies

Indoor unit

control board

* There are three types of labels (labels A, B, and C). Affix the appropriate labels to

the units according to the wiring method.

6. Electrical work

6.2. Remote controller

6.2.1. For wired remote controller

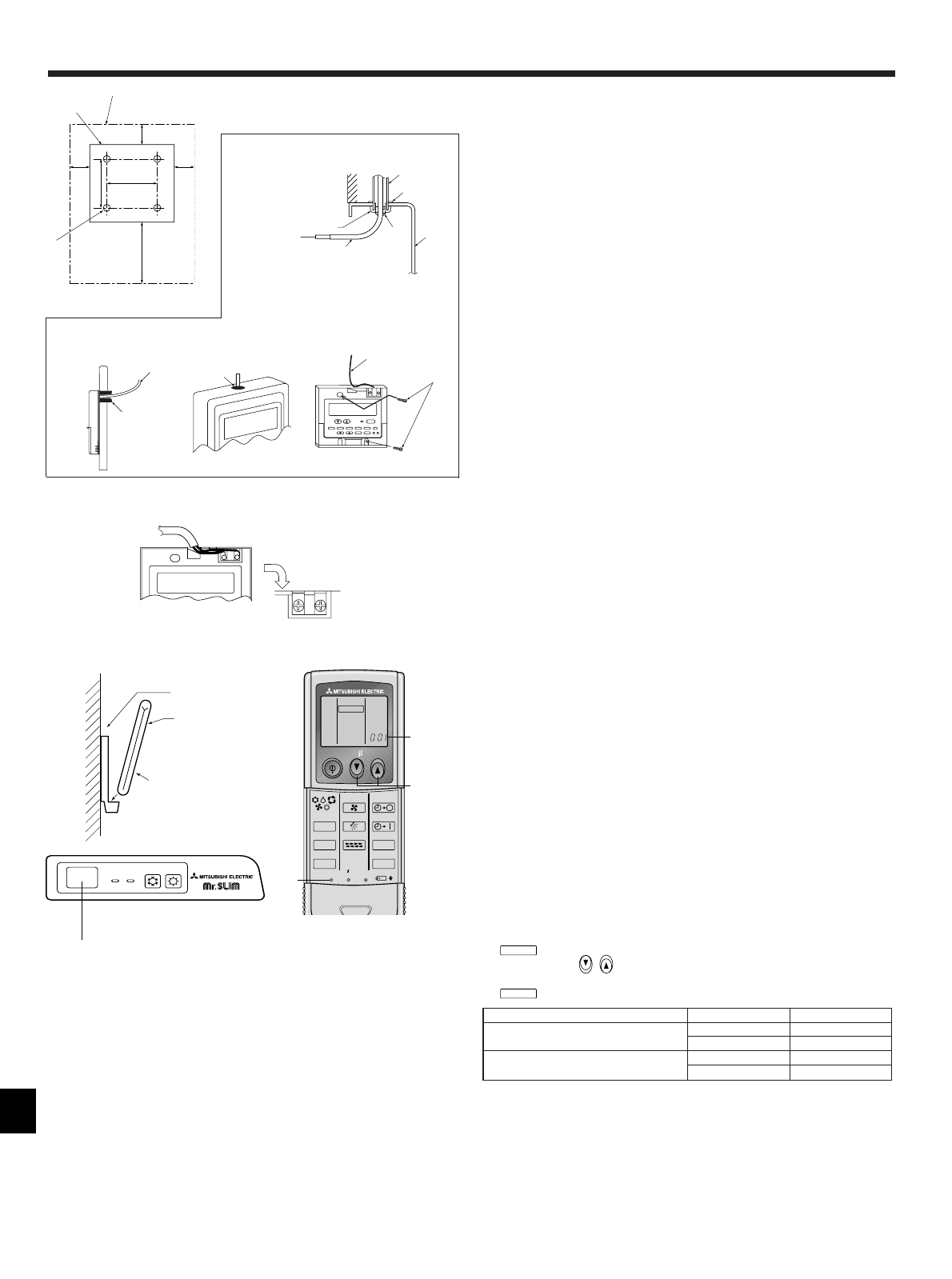

1) Installing procedures

(1) Select an installing position for the remote controller. (Fig. 6-2)

The temperature sensors are located on both remote controller and indoor unit.

s Procure the following parts locally:

Two piece switch box

Thin copper conduit tube

Lock nuts and bushings

A Remote controller profile

B Required clearances surrounding the remote controller

C Installation pitch

(2) Seal the service entrance for the remote controller cord with putty to prevent pos-

sible invasion of dew drops, water, cockroaches or worms. (Fig. 6-3)

A For installation in the switch box:

B For direct installation on the wall select one of the following:

• Prepare a hole through the wall to pass the remote controller cord (in order to run

the remote controller cord from the back), then seal the hole with putty.

• Run the remote controller cord through the cut-out upper case, then seal the cut-

out notch with putty similarly as above.

B-1. To lead the remote controller cord from the back of the controller:

B-2. To run the remote controller cord through the upper portion:

(3) For direct installation on the wall

C Wall

D Conduit

E Lock nut

F Bushing

G Switch box

H Remote controller cord

I Seal with putty

J Wood screw

2) Connecting procedures (Fig. 6-4)

1 Connect the remote controller cord to the terminal block.

A To TB5 on the indoor unit

B TB6 (No polarity)

3) Two remote controllers setting

If two remote controllers are connected, set one to “Main” and the other to “Sub”. For

setting procedures, refer to “Function selection of remote controller” in the operation

manual for the indoor unit.

6.2.2. For wireless remote controller

1) Installation area

• Area in which the remote controller is not exposed to direct sunshine.

• Area in which there is no nearby heating source.

• Area in which the remote controller is not exposed to cold (or hot) winds.

• Area in which the remote controller can be operated easily.

• Area in which the remote controller is beyond the reach of children.

2) Installation method (Fig. 6-5)

1 Attach the remote controller holder to the desired location using two tapping screws.

2 Place the lower end of the controller into the holder.

A Remote controller

B Wall

C Display panel

D Receiver

• The signal can travel up to approximately 7 meters, 23 ft (in a straight line) within 45

degrees to both right and left of the center line of the receiver.

3) Setting (Fig. 6-6)

1 Insert batteries.

2 Press the SET button with something sharp at the end.

MODEL SELECT

blinks and Model No. is lighted.

3 Press the temp

button to set the Model No.

4 Press the SET button with something sharp at the end.

MODEL SELECT

and Model No. are lighted for three seconds, then turned off.

B-1. B-2.

Fig. 6-3

Indoor Outdoor A Model No.

PLA, PCA, PKA (A12, A18)

heat pump models 001

cooling only models 033

PKA (A24, A30, A36)

heat pump models 003

cooling only models 035

Fig. 6-5

Fig. 6-6

Fig. 6-2

Fig. 6-4

ON

OFF

STAND

BY

COOL HEAT

D

B

1

C

A

2

1-3/16

1-37/64

1-3/16

1-3/16

4-23/32

3-9/32

A

B

C

F

A

H

C

D

E

G

I

I

I

H

B

A

AB TB6

B

ON/OFF TEMP

FAN

VANE

TEST RUN

AUTO STOP

AUTO START

h

min

LOUVER

MODE

CHECK

RESETSET CLOCK

MODEL SELECT

2,4

3

A

J

H