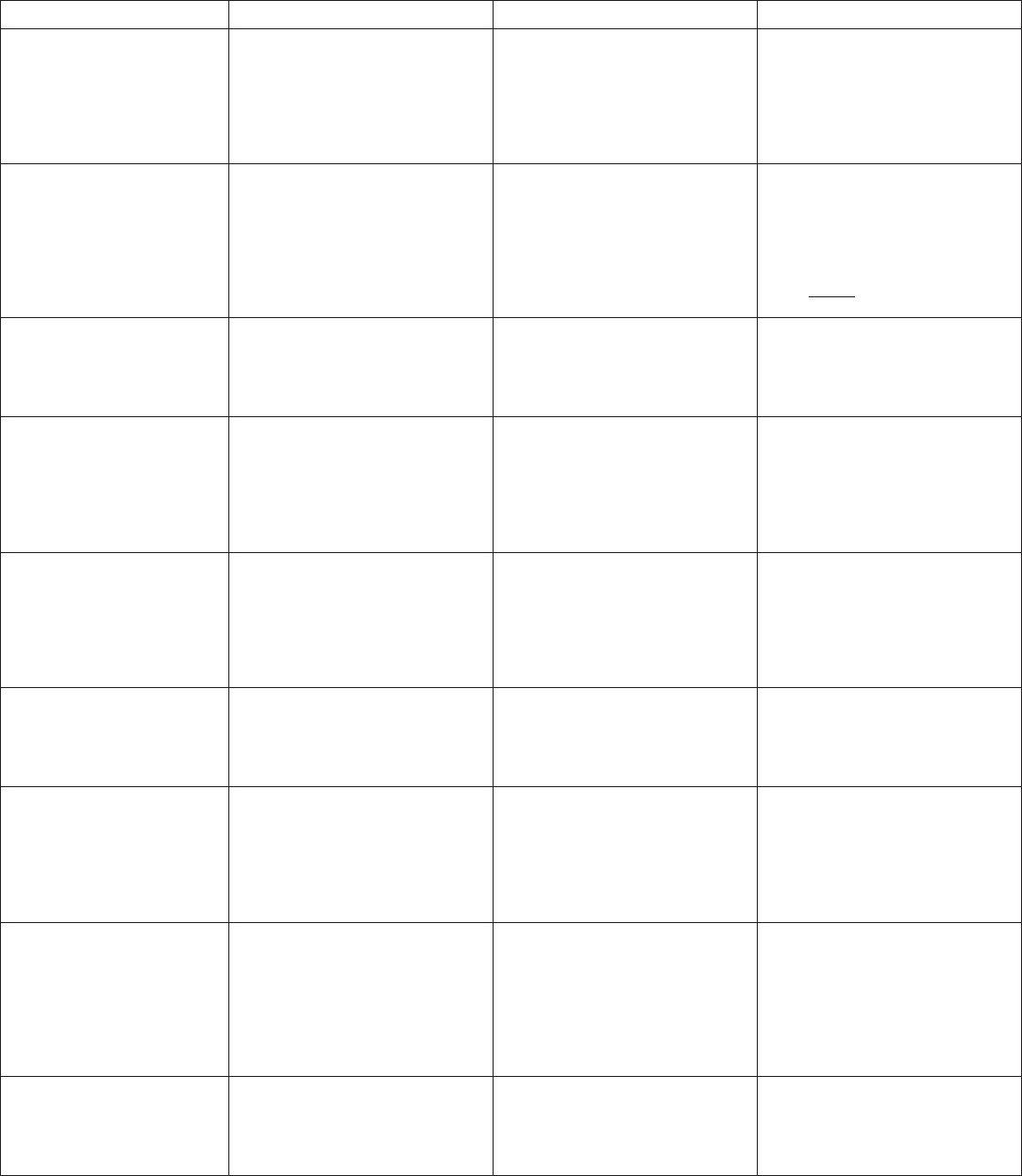

3200 & 4200 Series -- 62 –

MEYER FRONT & REAR FORAGE BOXES

“TROUBLE SHOOTING”

SYMPTOM PROBLEM SOLUTION

AUGERS

Augers shake or chatter.

Under load, augers do not start in 1st or

2nd notch

Stiff roller chains - dry.

Loose roller chains.

Worn sprockets/chains.

Bad roller bearings.

Variable speed not adjusted.

Lubricate roller chains.

Tighten roller chains.

Replace sprockets/chains.

Replace roller bearings.

Adjust variable speed.

BELT DRIVE

“VARIABLE SPEED”

Belt slippage.

Belt wear/breakage.

Sheave pin breakage.

Sheaves greasy or wet.

Use of “HI” Range w/full load.

Variable speed not adjusted.

PTO starting w/belt engaged.

Incorrect operating procedures.

PTO starting w/belt engaged.

Clean sheaves.

Use “LO” Range w/full loads.

Adjust variable speed.

Start PTO w/belt in “Neutral.”

Follow correct

operating procedures.

Start PTO w/belt in “Neutral.”

CROSS APRON

Material build-up under chain.

Bent apron slats.

Broken pintle chain.

Loose cross apron.

Dirtycrossapron, toomuchcarryback.

Build-up in clean-out panel.

Tighten cross apron.

Clean apron and return area.

Clean out “Clean-Out” panel.

GEAR BOXES

Clunking sounds.

Excessive gear wear.

Broken gears.

Gears/bearings wearing — low oil

Full load “HI” Range unloading.

Wrong gear lube oil.

High speed start-up/no oil.

Worn out gears.

Replace gears/bearings — fill with oil

Start full loads in “LO” Range.

Use #80-90 wt. gear lube oil.

Slow start-up/fill with oil.

Replace gears.

“HI-LO” RANGE

Hard to shift lever.

“HI-LO” is not engaging.

Slipping out of range.

Unit not running.

Worn brass shifting collar.

Excessive clutch wear.

Run unit with variable speed lever

engaged.

Replace brass shifting collar.

Adjust range control linkage.

Flip over or replace clutches.

MAIN APRON

Jumping links.

Bent apron slats.

Broken pintle chain.

Loose main apron.

Worn/broken chain.

Front unit sagging.

Tighten main apron.

Clean/tighten/replace apron.

Liftunitand replacefrontcrosschannel.

PTO SHAFT

Whips/shakes.

Vibrates up and down.

Worn universal joints.

Over extended or bent PTO.

Forage box center shaft bent.

Lack of lubrication/used

Shorten wagon gear hitch length.

Straighten/replace PTO.

Replace center shaft.

Lubricate joints daily/replace

ROLLER CHAINS

AND SPROCKETS

Excessive chain wear.

Roller chain breakage.

Sprocket teeth tipped over.

Lack of lubrication.

Out of alignment/loose.

Loose roller chain.

Worn sprockets.

Worn roller chain.

Bad roller bearings.

Lubricate/align/tighten.

Tighten roller chains.

Replace sprockets.

Replace roller chain.

Replace bearings.

SAFETY CLUTCH

Does not trip. Bad or damaged clutch.

Safety cable disconnected.

Safety cable broken.

Replace safety clutch.

Re-fasten safety cable.

Replace safety cable.