10

ENGLISH

A

Caution!

Do not lift pump at the cable or

discharge hose; both are not desig-

ned for the tensile load by the weight

of the pump.

1. Submerge pump at an angle to

avoid an air cushion at the under-

side, which would prevent priming.

Once the pump is submerged, it can

be set into an upright position.

2. Lower pump to the bottom of the

fluid container. Use a strong rope,

fastened to the cable eye, to lower

the pump.

The pump can also be operated

when suspended by a rope.

6.1 Switching ON and OFF

After connection to the mains, the sub-

mersible pump is automatically switched

ON and OFF by the float switch:

x It starts pumping when the fluid has

lifted the float switch fully (12).

x The pump switches OFF when the

float switch has fallen down (13).

The cable for the float switch can be

moved in the cable holder (14) to adjust

the distance between the switching ON

and OFF positions:

x Float switch on a "short cable": the

On and OFF positions are close

together.

x Float switch on a "long cable": the

On and OFF positions are wide

apart.

A

Caution!

The float switch must be able

to move in such way that the pump

can not run dry.

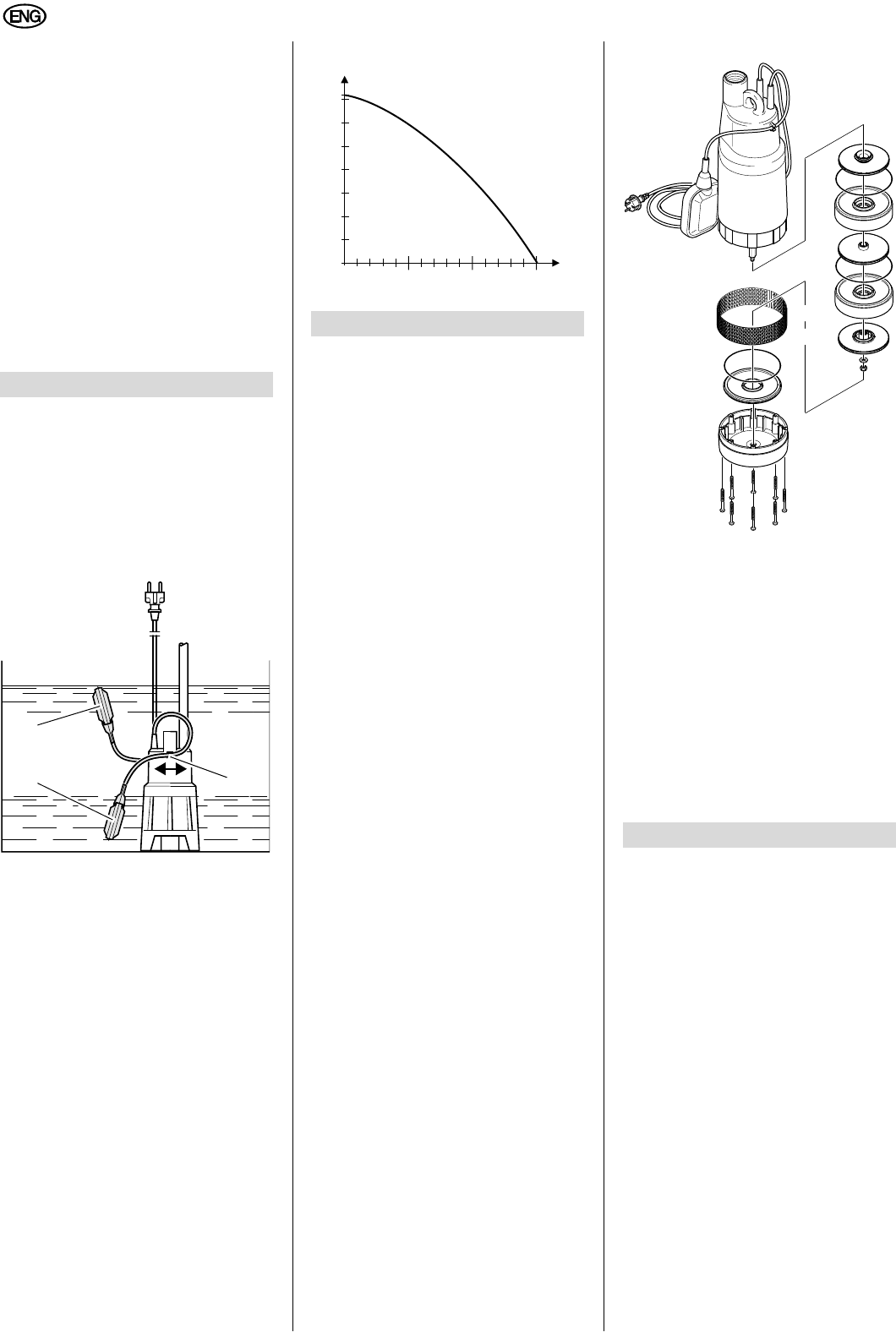

6.2 Pump characteristic

curve

The pump characteristic curve shows

which pump capacity is possible in

dependance on the delivery head.

A

Danger!

Prior to all servicing:

Switch Off.

Unplug.

Service and repair work other than

described here must be left to quali-

fied specialists.

7.1 Periodic maintenance

For the pump to function perfectly at any

time periodic maintenance is required.

This also applies if the pump is used

under heavy conditions, but does not run

for extended periods of time (e.g. when

used in well drains):

Yearly service

1. Check pump casing, cables and

float switch for damage.

2. Rinse pump with clear water.

Remove persistant soiling, e.g.

algae desposits, with brush and

dishwashing liquid.

3. To flush the inside of the pump,

place it into a container filled with

clear water and switch ON briefly.

Cleaning the impellers

A

Caution!

The impellers of a submersible pres-

sure pump are a complex component.

Some technical skill is therefore

required for cleaning. If you perform

the cleaning yourself, when disas-

sembling you must take note of the

assembly sequence and position of

the individual parts!

1. Remove strainer base.

2. Remove the impellers as illustrated.

3. Clean all component parts. Remove

persistant soiling with brush and

dishwashing liquid.

4. Reassemble pump.

7.2 Pump storage

A

Caution!

Frost damages the pump and

accessories, as both always contain

water!

x When there is danger of freezing

remove pump and accessories and

store at a frost-proof location.

A

Danger!

Prior to all servicing:

Switch Off.

Unplug.

8.1 Fault finding

Pump does not run:

x No mains voltage.

Check cables, plug, outlet and

mains fuse.

x Mains voltage too low.

Use only extension cables with

sufficient lead cross section (see

"Technical Specifications").

x Motor overheated, motor protection

relay tripped.

Remove cause for overheating

(fluid pumped too hot? Pump

blocked by foreign objects?)

After cooling off the pump will

switch ON again.

x Float switch does not switch the

pump ON.

6. Operation

14

12

13

7. Care and Maintenance

7500

l

/h

m

0

0

36

30

20

10

2500 5000

8. Trouble Shooting