-NLC-

ENGLISH

To obtain full benefit from the WA 41 A and

trouble free operation, read the following in-

structions and information carefully.

DESCRIPTION AND FUNCTION

* The control panel incorporates a

switch, a locking device for the fuel and a

pilot light.

* The electric pump motor drives the fuel

pump, which is positioned in the tank.

* The fuel pump delivers fuel to the com-

bustion dish and is controlled by means of

the button above the control panel,

At position low, the consumption is approx.

2,5 l/h. At position high, the consumption

is approx. 4,3 l/h.

One and another depends on viscosity.

* The main fan is controlled by a thermostat.

As soon as the combustion chamber has warmed

up sufficiently, the fan starts to operate.

* The burner is equipped with an air intake

fan to supply air for combustion. This air

combustion fan stops when the flame has

extinguished. Pipes φ 200 mm can be

connected to this fan so that the combustion

air can be sucked from outside the area to

be heated.

* Most types of waste oil can be used, such as

gearbox oil, gas oil, diesel oil, hydraulic

oil, HBO 1, 2 and 3, but not those with a

high viscosity, such as SAE90.

DO NOT USE TRANSFORMER OIL WHICH MIGHT

CONTAIN SUBSTANCES DETRIMENTAL TO THE

PERFORMANCE OF THE BURNER (PCB)

* When the pump motor stops, the flame will

extinguish once the fuel in the burner dish

is exhausted.

WARNINGS

1 There could be a possible danger of

explosion if the burner is reignited while

it is still warm.

2 There must be sufficient air for combustion;

make sure that the combustion air intake fan

is never blocked.

3 Modifications made to the burner by dealer

or end user, invalidate the manufacturer's

warranty.

INSTALLATION

* For installation, consult the local

prescriptions.

* The burner must be installed on a completely

level, concrete floor.

* Check that the chose position presents no

problem for:

- electrical supply 230V/2Amp.;

- flue pipe installation;

- combustion air supply.

* Open the top cover of the burner and remove

the cover of the combsution

chamber.

* The following items are packed within the

combustion chamber:

1x T-piece with built-in draught stabiliser

for flue pipe connection

1x cleaning shovel

1x scraping tool to remove residue from

combustion dish

1x combustion dish

2x burner ring

1x spare card to seal the bottom of com-

bustion chamber

2x handle with bolts

1x pedal

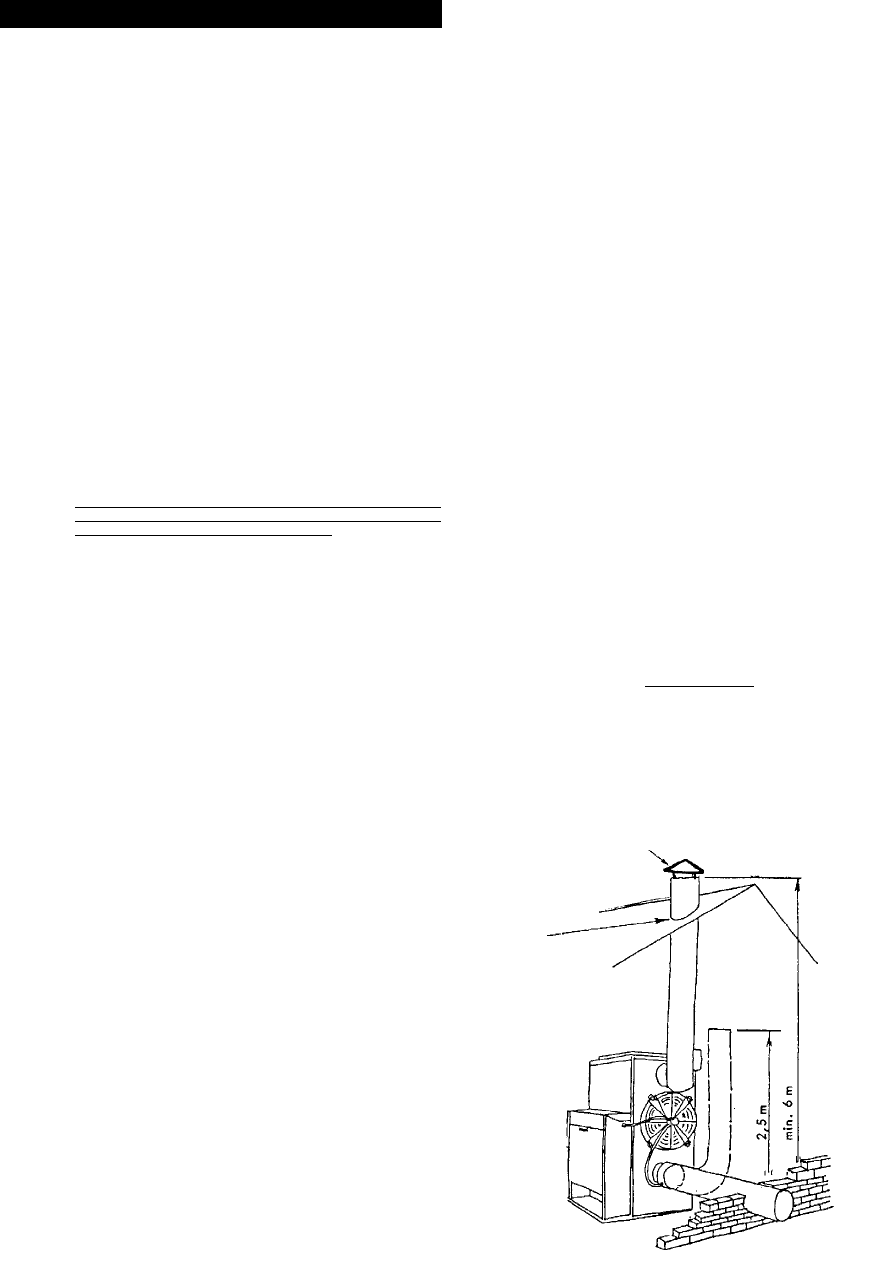

FLUE PIPE

For clean and trouble free combustion, it is

essential that the flue pipe is installed correctly.

a. minimum diameter of flue pipe: 150mm

b. check that flue connections are well sea-

led

c. minimum flue height: 5 m

d. the wind must be able to reach the top of

the flue from all directions (e.g.: it may

be necessary to extend flue above roof

apex)

e. all pipes should be vertical if possible,

keep horizontal pipes to the absolute

minimum

f. avoid bends in the flue installation if

possible but if unavoidable e.g. if flue

has two bends because of installation

through a wall or window, then:

1. the pipe should be as high as

possible within the building

2. flue pipe outside the building

should be insulated (double

walled)

3. the minimum height of the flue

has to be increased to 7.5 m to

compensate.

use a raincap