B-1

OPERATION

MINIFLEX

B-1

Read and understand this entire section before

operating your Miniflex.

SAFETY PRECAUTIONS

Always operate this equipment with the filters

installed and covers in place as these provide

maximum protection from moving parts and

insure proper vacuum operation and cooling air

flow.

-----------------------------------------------------------------------

RECOMMENDED USES

The Miniflex is a small, portable filtration unit designed

for light to medium duty weld applications and is used

for extracting and/or filtering fumes that are released

during the following welding processes:

• MIG/MAG solid wire (GMAW)

• MIG/MAG flux cored wire (FCAW)*

• Stick welding (SMAW)

• TIG (GTAW) welding

*For light flux-cored applications only.

Use of the product for extracting and/or filtering

fumes and/or gases that are released from the fol-

lowing processes is not recommended:

• Welding applications with intensive use of Tip Dip

(anti-spatter).

• Autogenic or plasma cutting spray/molten metal.

• Arc-air gouging.

• Welding that produces the release of a dense oil

mist.

• Paint spraying.

• Extraction of hot gases (more than 104° F, 40° C.)

• Extraction of aggressive fumes (such as acids).

• Grinding aluminum and magnesium.

• Flame spraying.

• Extraction of cement, saw dust, wood dust, etc.

• Extracting cigarettes, cigars, tissues and other

burning particles, objects and acids.

• Any dangerous situations where there is a risk of

an explosion or fire.

Note: The Miniflex does not filter any shielding

gases. Gases pass through the filter. Miniflex

used with optional carbon filter may reduce

vapors and gases.

OPERATING INSTRUCTIONS

The Miniflex provides enough suction for one fume

gun or small suction nozzle. Do not attach more than

one fume gun or suction nozzle to the Miniflex unit.

1. Connect the extraction hose at one side to the air

inlet of the machine (Figure B.1, Item A) and at the

other side to the welding torch or small suction noz-

zle.

2. Lay the work cable of the welding machine into the

slot on top of the machine (Figure B.2, Item A)

(when using Automatic Start/Stop mode).

3. Start up the machine by pressing the switch, locat-

ed on the side of the machine.

4. At the top of the unit, there is a High/Low button

and an Automatic Start/Stop Button (see Page B-2

for further instructions).

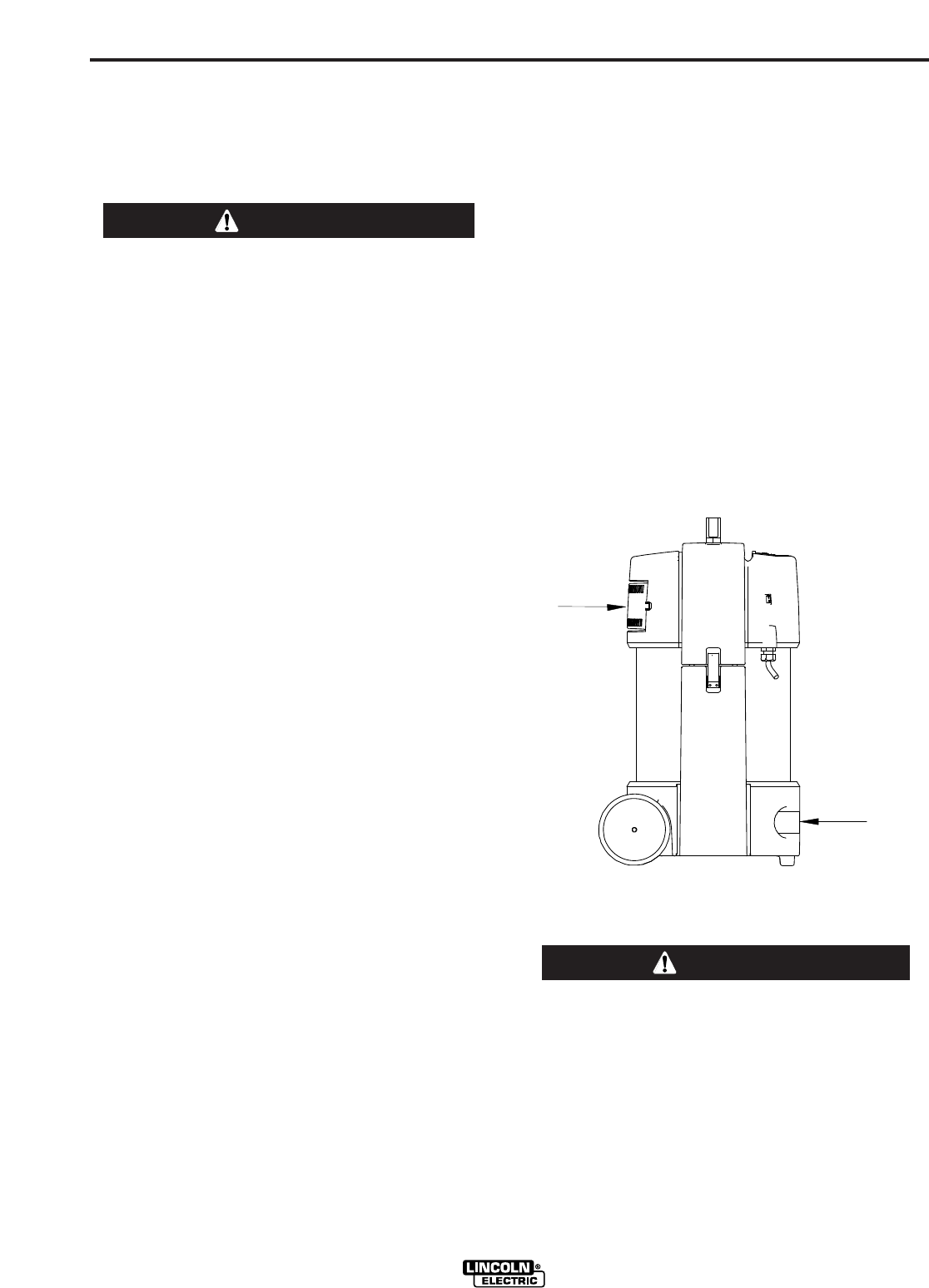

FIGURE B.1

Recommended Positioning: Upright

For optimal performance, unit is designed to operate

in upright position.

If unit is operated in an upright or horizontal posi-

tion, air inlet and outlet (Figure B.1, Items A and B)

must be free from obstruction.

WARNING

A

B

CAUTION