HAZARDLINE ENCLOSED INDUSTRIAL HSCXT SERIES

Page 2 of 4 CLASS I, DIVISION 2 LOCATIONS, GROUPS A,B,C,D; CLASS II, DIVISION I AND 2

GROUPS F AND G; CLASS III, DIVISION I, DIVISION 2 LOCATIONS, WET LOCATIONS

Lightolier a Genlyte Thomas Company www.lightolier.com

Technical Information: (978) 657-7600 • Fax (978) 658-0595

631 Airport Road, Fall River, MA 02720 • (508) 679-8131 • Fax (508) 674-4710

We reserve the right to change details of design, materials and finish.

© 2002 Genlyte Thomas Group LLC (Lightolier Division)

A0902 Section 7/Folio Q10-33

Job Information Type:

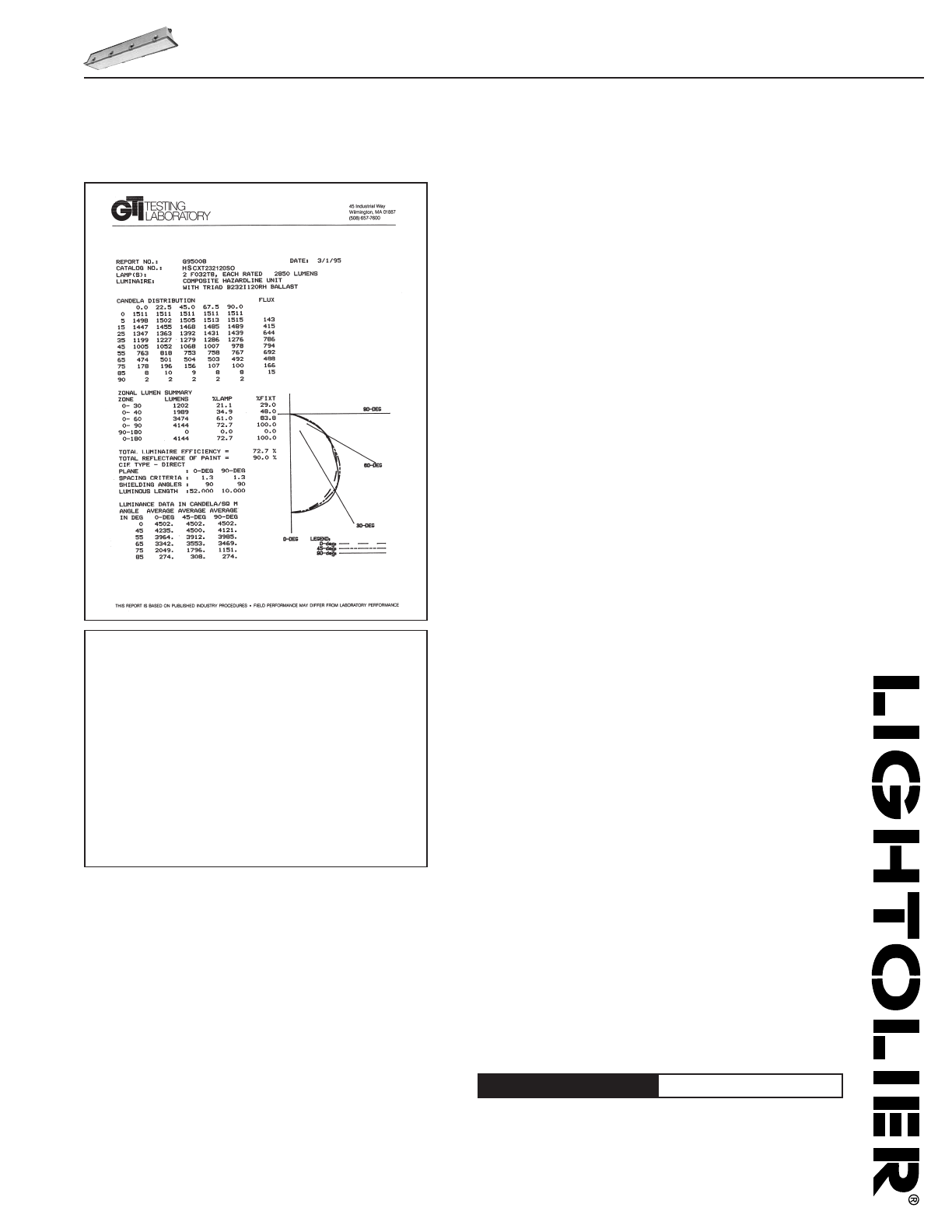

PHOTOMETRY

MODEL NO. HSCXT232

TYPICAL CLASS II LOCATIONS

• Grain elevators, flour and feed mills.

• Plants that have chemical or metallurgical processes...producers of plastics,

medicines and fireworks, etc.

• Producers of starch or candies.

• Spice-grinding plants, sugar plants and cocoa plants.

• Coal preparation plants and other carbon-handling or processing areas.

TYPICAL CLASS III LOCATIONS

• Textile mills, cotton gins, cotton seed mills and flax processing plants.

• Any plant that shapes, pulverizes or cuts wood and creates sawdust or

flyings.

Note: fibers and flyings are not likely to be suspended in the air, but can collect

around machinery or on lighting fixtures and where heat, a spark or hot metal

can ignite them.

CLASS I, DIVISION 2 LOCATIONS

A Class I, Division 2 location is a location: (1) in which volatile flammable liquids

or flammable gases are handled, processed, or used, but in which the liquids,

vapors, or gases will normally be confined within closed containers or closed

systems from which they can escape only in case of accidental rupture or break-

down of such containers or systems, or in case of abnormal operation of equip-

ment, or (2) in which concentrations of ignitible gases or vapors are normally

prevented by positive mechanical ventilation, but which might become haz-

ardous through failure or abnormal operation of the ventilating equipment; or (3)

that is adjacent to a Class I, Division 1 location, and to which concentrations of

ignitible gases or vapors might occasionally be communicated unless such com-

munication is prevented by adequate positive-pressure ventilation from a source

of clean air, and effective safeguards against ventilation failure are provided.

This classification usually includes locations where volatile flammable liquids or

flammable gases or vapors are used, but which, in the judgment of the authority

having jurisdiction, would become hazardous only in case of an accident or of

some unusual operating condition, The quantity of hazardous material that

might escape in case of accident, the adequacy of ventilating equipment, the

total area involved, and the record of the industry or business with respect to

explosions or fires are all factors that merit consideration in determining the

classification and extent of each location.

Piping without valves, checks, meters, and similar devices would not ordinarily

introduce a hazardous

condition even though used for flammable liquids or gases. Locations used for

the storage of flammable

liquids or of liquefied or compressed gases in sealed containers would not nor-

mally be considered hazardous unless subject to other hazardous conditions

also.

Electrical conduits and their associated enclosures separated from process flu-

ids by a single seal or barrier shall be classed as a Division 2 location if the out-

side of the conduit and enclosures is an unclassified location.

Typical Class I Locations:

• Petroleum refineries, and gasoline storage and dispensing areas.

• Industrial firms that use flammable liquids in dip tanks for parts

cleaning or other operations.

• Petrochemical companies that manufacture chemicals from gas

and oil.

• Dry cleaning plants where vapors from cleaning fluids can be

present.

• Companies that have spraying areas where they coat products

with liquid paint or plastics.

• Aircraft hangers and fuel servicing areas.

• Utility gas plants and operations involving storage and handling of

liquefied petroleum gas or natural gas.