Service Manual 57

Troubleshooting Guide

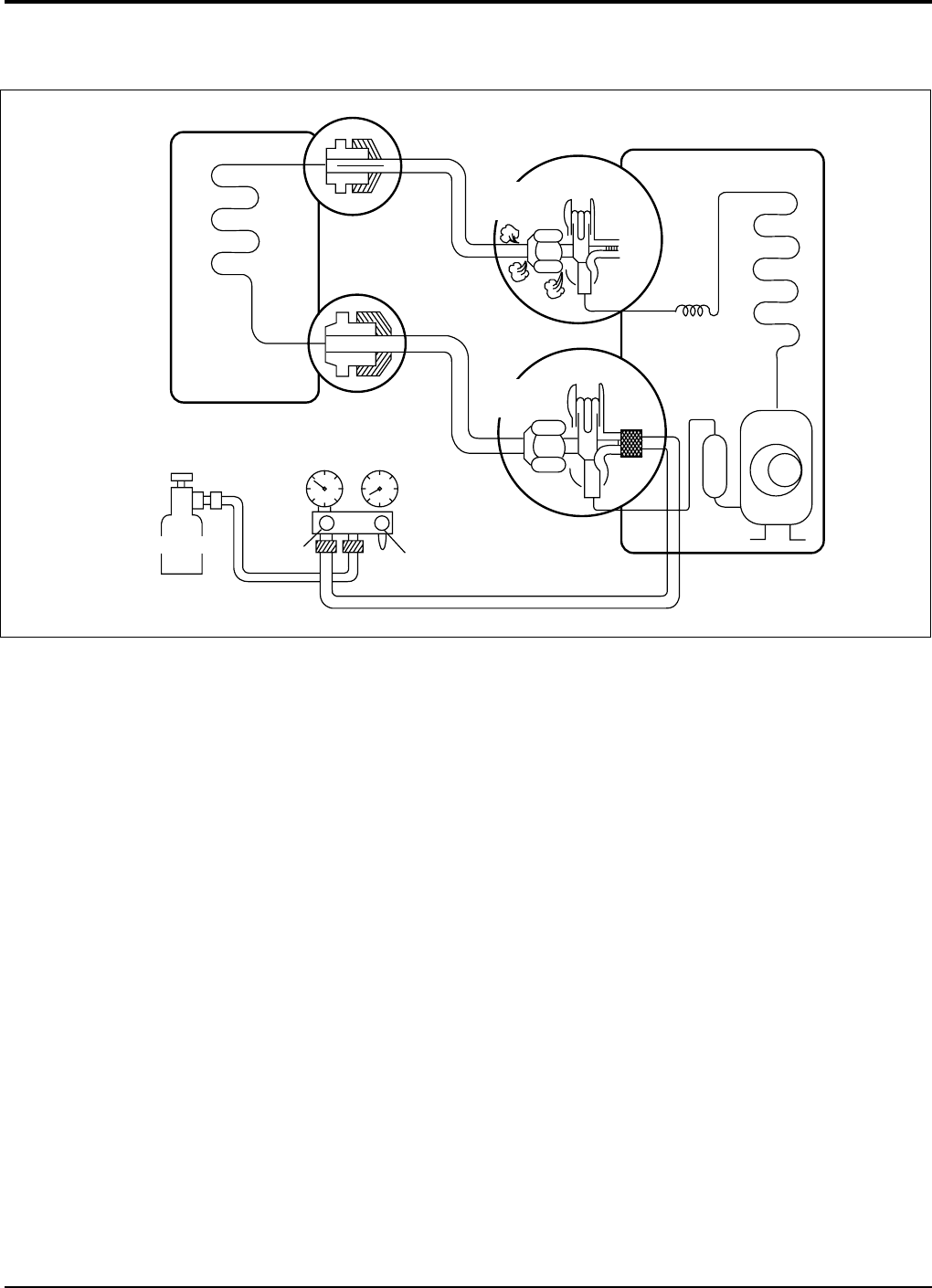

1) Re-air purging

(Re-installation)

• Procedure

(1) Confirm that both the liquid side valve and the

gas side valve are set to the closed position.

(2) Connect the charge set and a gas cylinder to

the service port of the Gas side valve.

– Leave the valve on the gas cylinder closed.

(3) Air purging.

– Open the valves on the gas cylinder and the

charge set. Purge the air by loosening the flare

nut on the liquid side valve approximately 45°

for 3 seconds then closing it for 1 minute;

repeat 3 times.

– After purging the air, use a torque wrench to

tighten the flare nut on liquid side valve.

(4) Check for gas leakage.

– Check the flare connections for gas leakage.

(5) Discharge the refrigerant.

– Close the valve on the gas cylinder and dis-

charge the refrigerant until the gauge indicates

3 to 5 kg/cm

2

g.

(6) Disconnect the charge set and the gas cylin-

der, and set the Liquid side and Gas side

valves to the open position.

– Be sure to use a hexagonal wrench to operate

the valve stems.

(7) Mount the valve stem nuts and the service

port nut.

– Use torque wrench to tighten the service port

nut to a torque of 1.8 kg.m.

– Be sure to check for gas leakage.

* CAUTION:

Do not leak the gas in the air during Air

Purging.

Lo

Closed

OPEN

Closed

Gas cylinder

Outdoor unit

Indoor unit

Liquid side

Gas side

CLOSE

3-Way

valve

3-Way

valve

Refrigerant