Installation of Unit

Installation Manual 13

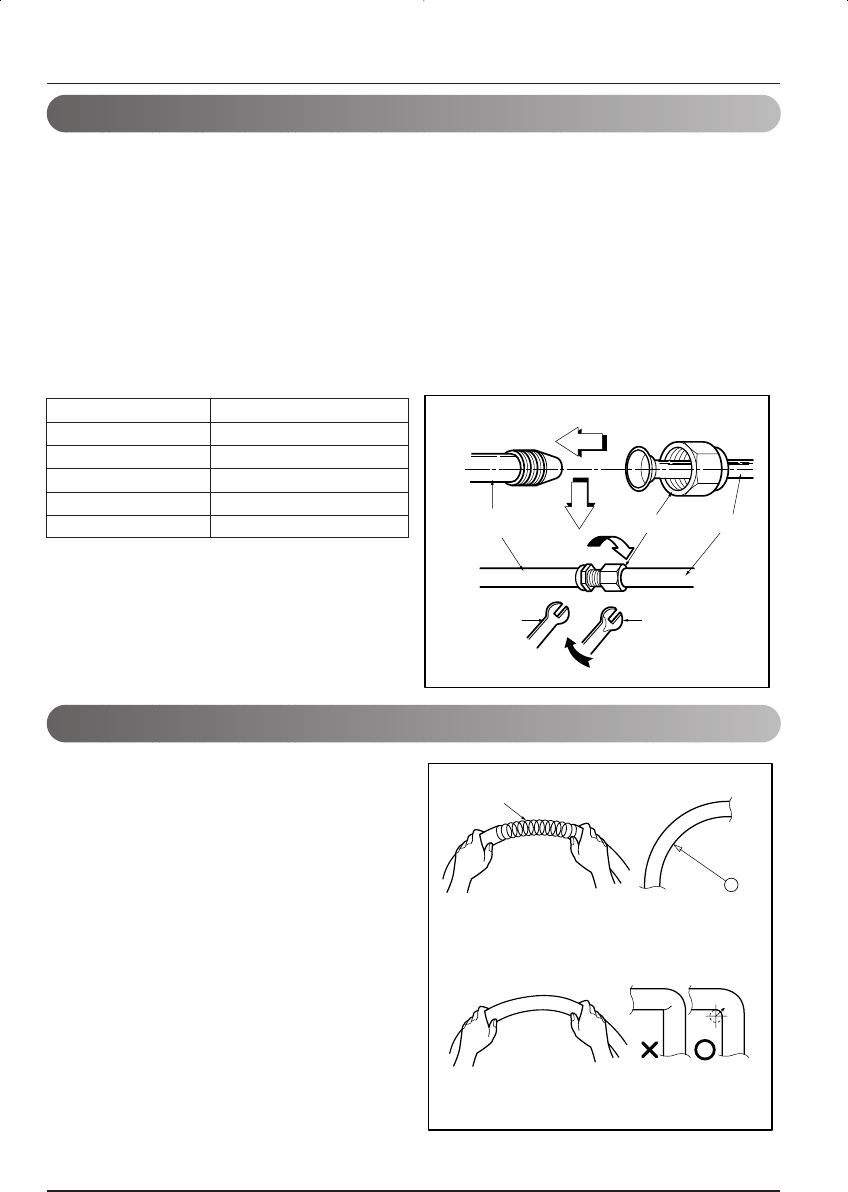

Connection of piping

• Align the center of the pipings and suffciently

tighten the flare nut with fingers.

• Finally, tighten the flare nut with troque

wrench until the wrench clicks.

When tightening the flare nut with troque

wrench, ensure the direction for tightening

follows the arrow on the wrench.

1.

If it is necessary to bend or stretch the

tubing, use the spring which is attached to

the tubing in stead of pipe bender.

• Please make a careful notice to make a

smooth line.

• Hold the tubing with your two hands closely

and then bend or stretch it slowly not to

make any crack.

• Remember that the radius (R) should not

exceed 70mm (Refer to Fig. 1)

2. Do not repeat the bending process to prevent

the tubing from cracking or crushing.

3. Keep in mind that the bending part should

not be cracked and make the radius (R) as

long as possible (Refer to Fig. 2)

1. Move the indoor tubing and drain hose to the hole

• Remove tubing holder and pull the tubing out of the chassis.

2. Replace the tubing holder into original position

3. Route the tubing and the drain hose staight backwards.

4. Insert the connecting cable into the indoor unit through the hole.

• Do not connect the cable to the indoor unit

• Make a small loop with the cable for easy connection later.

5.Tape the tubing and the connecting cable.

6. Indoor unit installation.

7. Connecting the pipings to the indoor unit.

Precautions in bending

Indoor unit tubing

Flare nut

Pipings

Torque wrench

Spanner

Spring

R70mm

(Fig. 1)

(Fig. 2)

R

PIPE SIZE TORQUE

1/4" 1.8~2.5 kgf·m

3/8" 3.4~4.2 kgf·m

1/2" 5.5~6.6 kgf·m

5/8" 6.3~8.2 kgf·m

3/4" 9.9~12.1 kgf·m