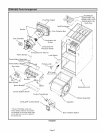

CHIMNEY

OR GAS

VENT_

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM OUTSIDE

(All Air Through Ventilated Attic)

VENTILATION LOUVERS

(Each end of attic)

FURNACE

INLET AIR

(Ends 12 in.

above bottom)

HEATER

NO TE- The inlet and outlet air openings shall each have a

free area of at least one square inch (645 mm 2)per 4,000

Btu (1.17 kW) per hour of the total input rating of all equip-

ment in the enclosure.

FIGURE 4

A _ EQUIPMENT IN

TT'_. JJ_ CONFINED SPACE

I I "_'Y _ ALLAIRFROM

I 1

OUTLET AIR

FURNACE

I1"- ,,

I ii I I I I I I I I I I I

NOTE - Each air duct opening shall have a free area of at least

o 2

ne square inch (645 mm J per 2, 000 Btu (.59 kW) per hour of

the total input rating of all equipment in the enclosure. If the

equipment room is located against an outside wall and the air

openings communicate directly with the outdoors, each open-

ing shall have a free area of at least one square inch (645 mm 2)

per4,000 Btu (1.17 kW) per hour of the total input rating of all

other equipment in the enclosure.

FIGURE 5

-&WARNING

The G50UH(X) gas furnace can be installed as shipped

in either the upfiow position or the horizontal position,

with right-hand or left-hand air discharge.

Select a location that allows for the required clearances

that are listed on the unit nameplate. Also consider gas

supply connections, electrical supply, vent connection,

and installation and service clearances [24 inches (610

mm) at unit front]. The unit must be level.

NOTE - 1/3 hp blower motors are equipped with four flex-

ible mounting legs. 1/2 hp blower motors are equipped with

three flexible legs and one rigid leg. The rigid leg is

equipped with a shipping bolt and a flat white plastic wash-

er (rather than the rubber mounting grommet used with a

flexible mounting leg). The bolt and washer must be re-

moved before the furnace is placed into operation. Af-

ter the bolt and washer have been removed, the rigid leg

will not touch the blower housing.

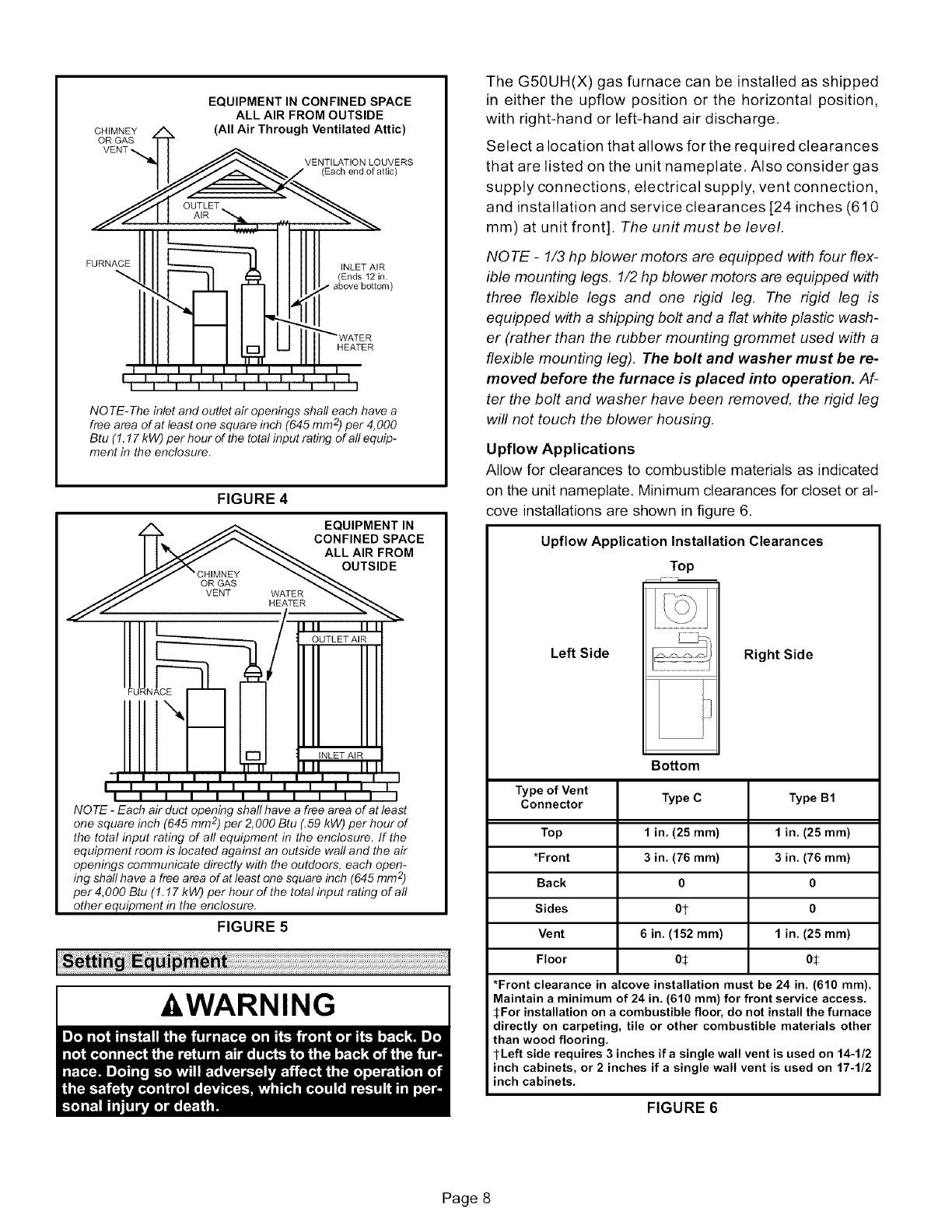

Upflow Applications

Allow for clearances to combustible materials as indicated

on the unit nameplate. Minimum clearances for closet or al-

cove installations are shown in figure 6.

Upflow Application Installation Clearances

Top

Left Side

Right Side

Type of Vent

Connector

Top

*Front

Back

Sides

Vent

Floor

Bottom

Type C

1 in, (25 ram)

3 in, (76 ram)

0

Ot

6 in. (152 ram)

05

Type B1

1 in, (25 ram)

3 in, (76 ram)

0

0

1 in. (25 ram)

0J;

*Front clearance in alcove installation must be 24 in. (610 ram).

Maintain a minimum of 24 in. (610 ram) for front service access.

SFor installation on a combustible floor, do not install the furnace

directly on carpeting, tile or other combustible materials other

than wood flooring.

l-Left side requires 3 inches ifa single wall vent is used on 14-1/2

inch cabinets, or 2 inches if a single wall vent is used on 17-1/2

inch cabinets.

FIGURE 6

Page 8