Lennox G32Q units are CSA International certified to

ANSI Z21.47 and CSA 2.3 standards.

In the USA, installation of Lennox gas central furnaces

must conform with local building codes. In the absence of

local codes, units must be installed according to the cur-

rent National Fuel Gas Code (ANSI-Z223.1) in the United

States. The National Fuel Gas Code is available from the

following address:

Amedcan National Standards Institute, Inc.

11 West 42rid Street

New York, NY 10036

In Canada, installation must conform with current Nation-

al Standard of Canada CAN/CGA-B149.1 "Installation

Code for Natural Gas Burning Appliances and Equip-

ment" and CAN/CGA-B149.2 "Installation Code for Pro-

pane Gas Burning Appliances and Equipment," local

plumbing or waste water codes and other applicable local

codes.

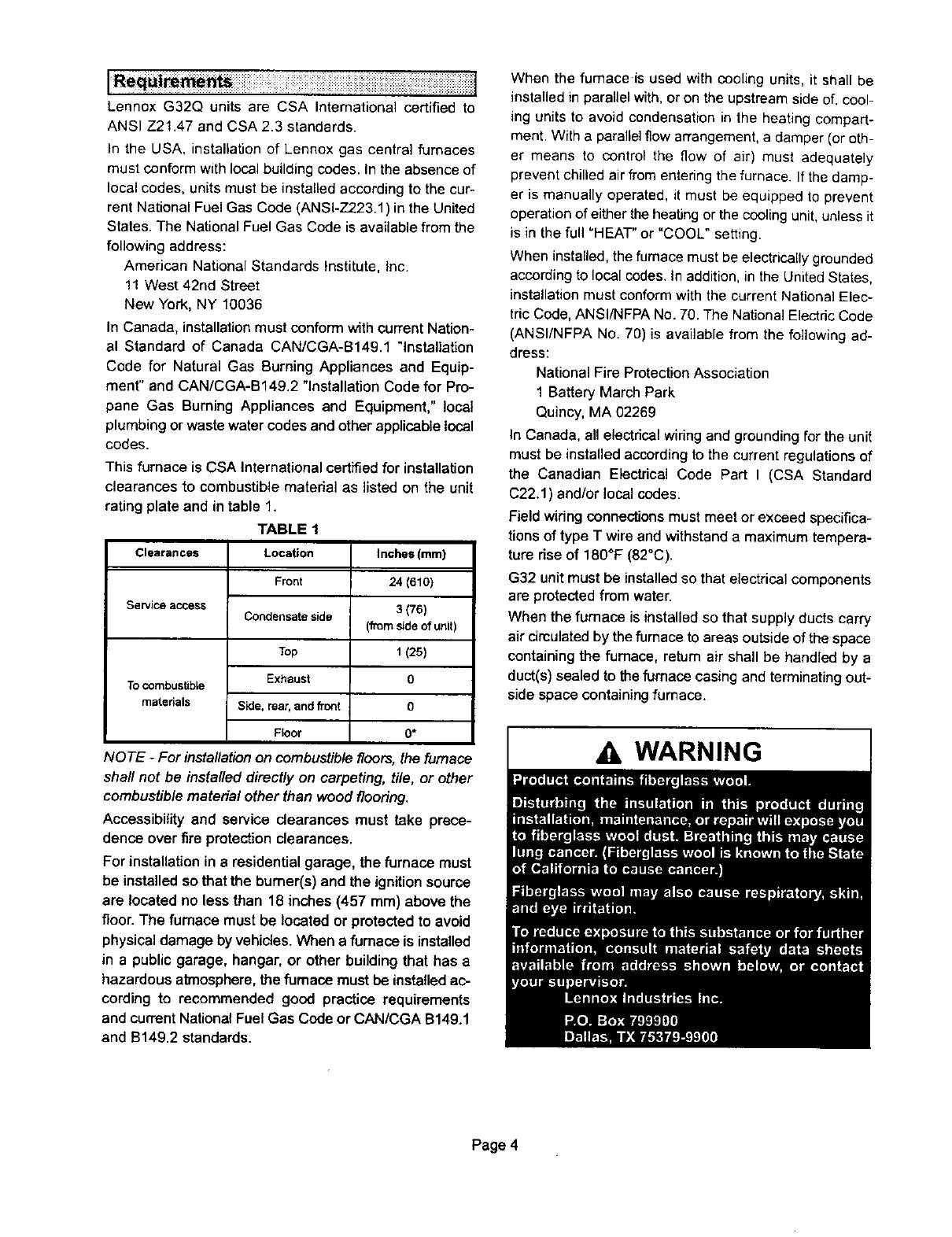

This furnace is CSA International certified for installation

clearances to combustible matedal as listed on the unit

rating plate and in table 1.

TABLE 1

Clearances Location

Front

Service access

Condensate side

Top

Exhaust

To combustible

materials Side, rear,and front

Floor

Inches (mrn)

24 (610)

3 (76)

(fromsideofunit)

1(2s)

0

0

0*

NOTE - For installation on combustiblefleers, the furnace

shaft not be installed directly on carpeting, tile, or other

combustible material other than wood flooring.

Accessibility and service clearances must take prece-

dence over fire protectionclearances.

For installation in a residential garage, the furnace must

be installed so that the burner(s) and the ignition source

are located no less than 18 inches (457 mm) above the

floor. The furnace must be located or protected to avoid

physical damage by vehicles. When e furnace is installed

in a public garage, hangar, or other building that has a

hazardous atmosphere,the fumace mustbe installed ac-

cording to recommended good practice requirements

and current National Fuel Gas Code or CAN/CGA B149.1

and B149.2 standards.

When the furnace is used with cooling units, it shall be

installed in parallel with, or on the upstream side of. cool-

ing units to avoid condensation in the heating compart-

ment. With a parallel flow arrangement, a damper (or oth-

er means to control the flow of air) must adequately

prevent chilled air from entering the furnace. If the damp-

er is manually operated, it must be equipped to prevent

operation of either the heating or the cooling unit, unless it

is in the full =HEAT" or "COOL" setting.

When installed, the furnace must be electrically grounded

according to local codes. In addition, in the United States,

installation must conform with the current National Elec-

tric Code, ANSI/NFPA No. 70. The National Electric Code

(ANSI/NFPA No. 70) is available from the following ad-

dress:

National Fire Protection Association

1 Battery March Park

Quincy, MA 02269

In Canada, all electrical wiring and grounding for the unit

must be installed according to the current regulations of

the Canadian Electrical Code Part I (CSA Standard

C22.1 ) and/or local codes.

Field widng connections must meet or exceed specifica-

tions of type T wire and withstand a maximum tempera-

ture dee of 180°F (82°C).

G32 unit must be installed so that electrical components

are protected from water.

When the furnace is installed so that supply ducts carry

air circulated by the furnace to areas outside of the space

containing the furnace, return air shall be handled by a

duct(s) sealed to the furnace casing and terminating out-

side space containing furnace.

A WARNING

Page 4