Page 13

Unit Start−Up and Operation

Each 15CHAX packaged cooling unit is factory−charged

with R−410A refrigerant. The compressor is hermetically

sealed, internally sprung and base−mounted with

rubber−insulated hold−down bolts.

Pre−Start Check List:

1 − Make sure refrigerant lines do not rub against the cabi-

net or each other.

2 − Inspect all electrical wiring, both factory− and field−

installed, for loose connections.

3 − Check voltage at the disconnect switch. Voltage must

be within the range listed on the unit nameplate. If not,

consult power company and have voltage condition

corrected before starting unit.

4 − Recheck voltage with unit running. If power is not with-

in the range listed on the unit nameplate, stop the unit

and consult the power company. Check unit amper-

age. Refer to unit nameplate for correct running amps.

5 − Make sure filter is in place before unit start−up.

6 − Before placing the unit into full operation, energize the

unit for three false starts. Energize the compressor

just long enough for it to make a few revolutions, wait

five to seven minutes before repeating a second and

third time.

Cooling Sequence of Operation

When the thermostat calls for cooling, the R" to Y" circuit

is closed to energize the compressor contactor. The

contactor brings on both the compressor and outdoor fan.

The thermostat also closes the R" to G" circuit to energize

the circulating air blower. When the cooling demand is

satisfied, the thermostat opens the circuits, as well as the

compressor contactor. The compressor and outdoor fan

immediately stop. The circulating air blower continues

operating through a 90−second delay.

Unit compressors have internal protection. If there is an

abnormal rise in the compressor temperature, the

protector will open and the compressor will stop.

System Performance

For maximum performance of this cooling system, the

operating temperatures and pressure should be checked

and subcooling determined at Standard ARI test conditions

of 82_ F outdoor temperature / 80_ F indoor dry bulb / 67_ F

indoor wet bulb. If subcooling measured deviates from

values in table 6, refrigerant charge should be adjusted

accordingly for maximum performance.

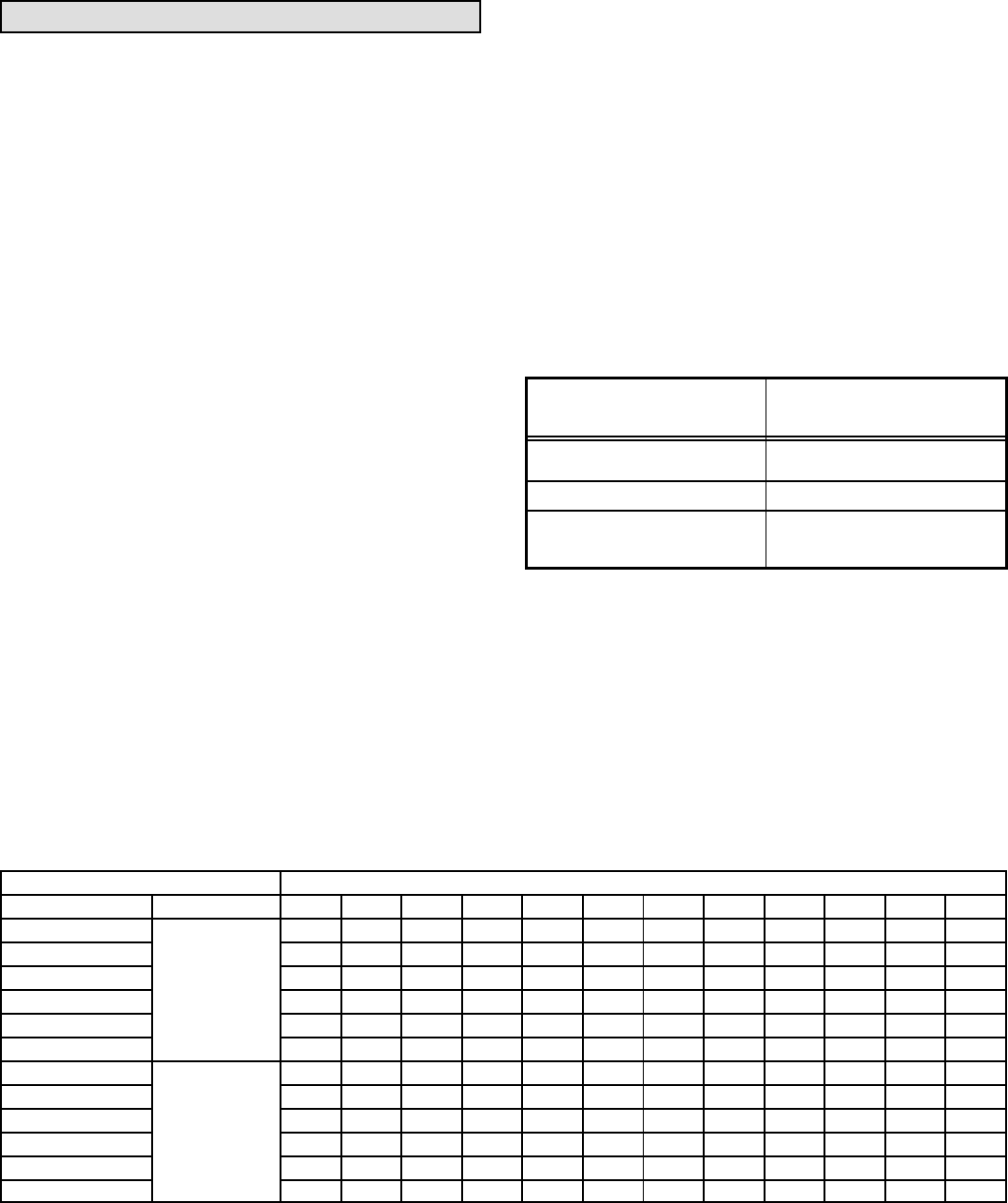

Table 6

Suction Superheat Values

Unit Model No.

Suction Superheat

82_F OD / 80_F IDDB

/ 67_F IDWB

15CHAX−24

15CHAX−30

12_

15CHAX−36 15_

15CHAX−42

15CHAX−48

15CHAX−60

10_

Verify system performance using table 7 as a general

guide. Table 7 should not be used for charging unit. Minor

variations in these pressures may be expected due to dif-

ferences in installations. Significant differences could

mean that the system is not properly charged or that a prob-

lem exists with some component in the system.

Used carefully, this table could serve as a useful service

guide. Data is based on 80°F dry bulb / 67°F wet bulb return

air. Allow unit operation to stabilize before taking pressure

readings.

Table 7

Normal Operating Pressures

80°F db / 67°F wb RETURN AIR Air Temperature Entering Outdoor Coil (°F)

UNIT PRESSURE 65 70 75 80 82 85 90 95 100 105 110 115

15CHAX−24 142 143 144 146 146 147 148 149 150 151 152 153

15CHAX−30 134 136 138 140 141 142 144 146 148 149 151 152

15CHAX−36

Suction

143 144 146 147 148 149 151 152 155 155 157 157

15CHAX−42

Suction

140 140 140 141 141 141 142 142 143 144 145 147

15CHAX−48 140 141 142 144 144 145 146 147 148 149 150 151

15CHAX−60 143 144 145 146 146 147 147 148 149 150 151 152

15CHAX−24 219 242 264 287 296 310 333 355 379 398 430 457

15CHAX−30 232 255 277 300 309 323 345 368 390 408 440 470

15CHAX−36

Liquid

244 268 292 316 326 340 363 369 410 429 461 493

15CHAX−42

Liquid

225 247 269 291 300 314 337 357 383 402 434 457

15CHAX−48 243 264 285 307 315 328 349 370 391 408 440 470

15CHAX−60 257 280 303 326 335 349 372 395 418 436 468 497