NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

4

Massachusetts And New York City, NY Re-

quirements

These appliances are approved for installation

in the following USA locations listed in the

following:

Massachusetts:

These fireplaces are approved for installation in

the US state of Massachusetts if the following

additional requirements are met-

• Installation and repair must be done by a

plumber or gas fitter licensed in the Common

-

wealth of Massachusetts.

• The flexible gas line connector used shall not

exceed 36 inches (92 centimeters) in length.

• The individual manual shut-off must be a

T-handle type valve.

Massachusetts Horizontal Vent Requirements

In the Commonwealth of Massachusetts, hori-

zontal terminations installed less than seven

(7) feet above the finished grade must comply

with the following additional requirements:

• A hard wired carbon monoxide detector with

an alarm and battery back-up must be installed

on the floor level where the gas fireplace is

installed. The carbon monoxide detector must

comply with NFPA 720, be ANSI/UL 2034 listed

and be ISA certified.

• A metal or plastic identification plate must

be permanently mounted to the exterior of the

building at a minimum height of eight (8) feet

above grade and be directly in line with the

horizontal termination. The sign must read,

in print size no less than one-half (1/2) inch

in size, GAS VENT DIRECTLY BELOW. KEEP

CLEAR OF ALL OBSTRUCTIONS.

New York City, NY:

These fireplaces are approved for installation in

New York City in the US state of New York.

COLD CLIMATE INSULATION

For cold climate installations, seal all cracks

around the appliance with noncombustible

material and wherever cold air could enter

the room. It is especially important to insulate

outside chase cavity between studs and under

floor on which the appliance rests, if floor is

above ground level. Gas line holes and other

openings should be caulked or stuffed with

unfaced fiberglass insulation. If the fireplace

is being installed on a cement slab, in cold

climates, a sheet of plywood or other raised

platform can be placed underneath to prevent

conducting cold up into the room. It also helps to

sheetrock inside surfaces and tape for maximum

air tightness and caulk firestops.

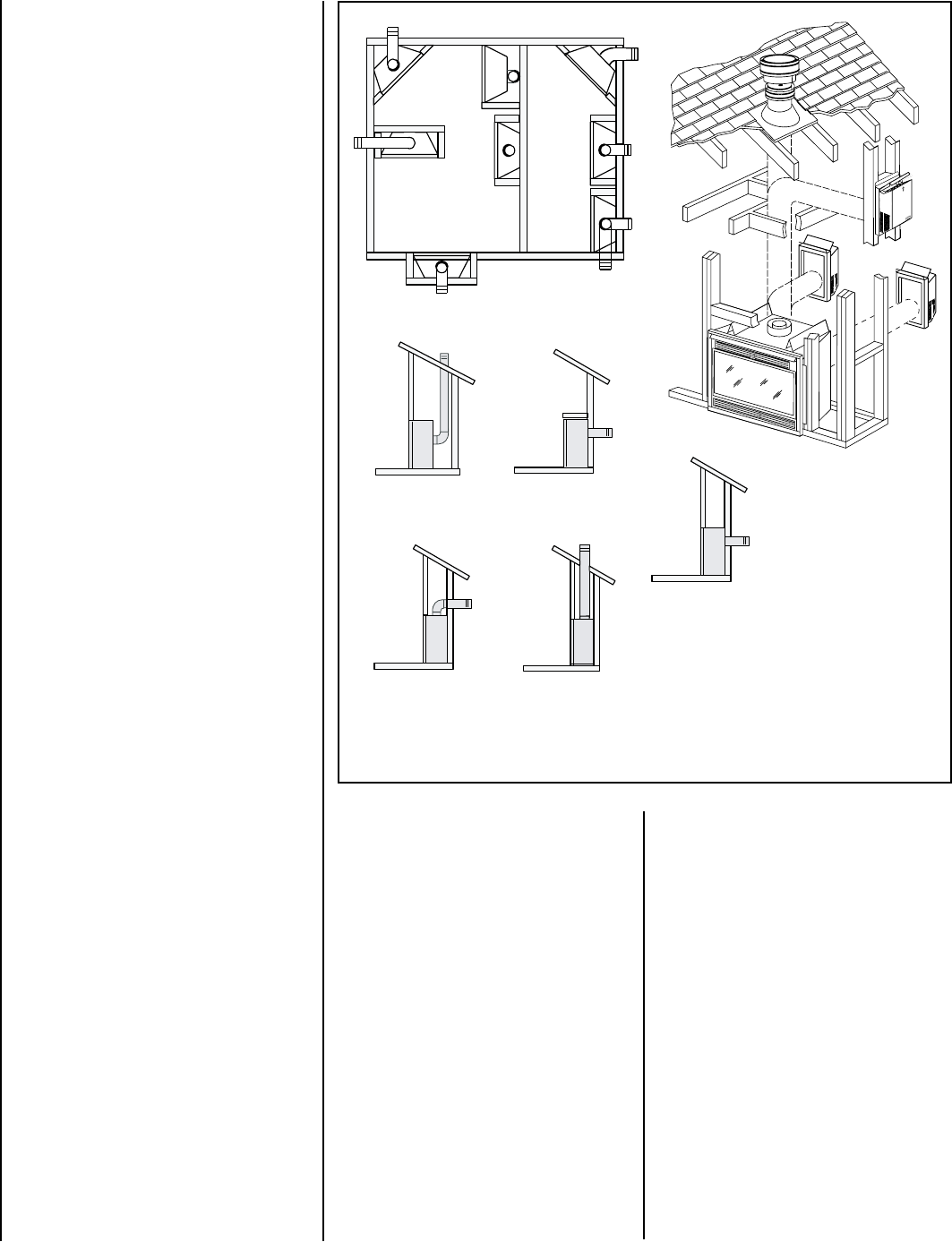

Figure 4 - Typical Locations

N

O

I

T

A

C

I

L

P

P

A

T

N

E

V

R

A

E

R

N

O

I

T

A

C

IL

P

P

A

T

N

E

V

P

O

T

APPLICATION

TOP VENT

TNEV RAE

R

NOITAC

I

LPPA

TNEV

P

OT

NO

I

T

A

CILP

PA

RECESSED

INSTALLATION

TOP VENT

APPLICATION

NOITACILPPA

TN

E

V POT

NOITACILPPA

TNEV POT

(Rear Vent

VERTICAL VENT

Application)

(Rear Vent Application

HORIZONTAL VENT

without a chase)

HORIZONTAL VENT

(Rear Vent Application

With a chase)

VERTICAL VENT

(Top Vent

Application)

HORIZONTAL VENT

(Top Vent

Application)

LOCATION

In selecting the location, the aesthetic and func-

tional use of the appliance are primary concerns.

However, vent system routing to the exterior and

access to the fuel supply are also important.

Consideration should be given to traffic ways,

furniture, draperies, etc., due to elevated surface

temperatures (Figure 4). The location should

also be free of electrical, plumbing or other

heating/air conditioning ducting.

These direct vent appliances are uniquely

suited for installations requiring a utility shelf

positioned directly above the fireplace. Utility

shelves like these are commonly used for locat-

ing television sets and decorative plants. Be

aware that this is a heat producing appliance.

Objects placed above the unit are exposed to

elevated temperatures.

To provide for the lowest possible shelf surface

use the alternate rear vent outlet with attached

venting routed in a way to minimize obstructions

to the use of the space above the appliance.

Do

not insulate the space between the appliance

and the area above it. See Figure 9. The mini-

mum height from the base of the appliance to

the underside of combustible materials used to

construct a utility shelf in this fashion is shown

in the Table in Figure 9.

The appliance should be mounted on a fully

supported base extending the full width and

depth of the unit. The appliance may be located

on or near conventional construction materials.

However, if installed on combustible materials,

such as carpeting, vinyl tile, etc., a metal or

wood barrier covering the entire bottom surface

must be used.