42

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Figure 72

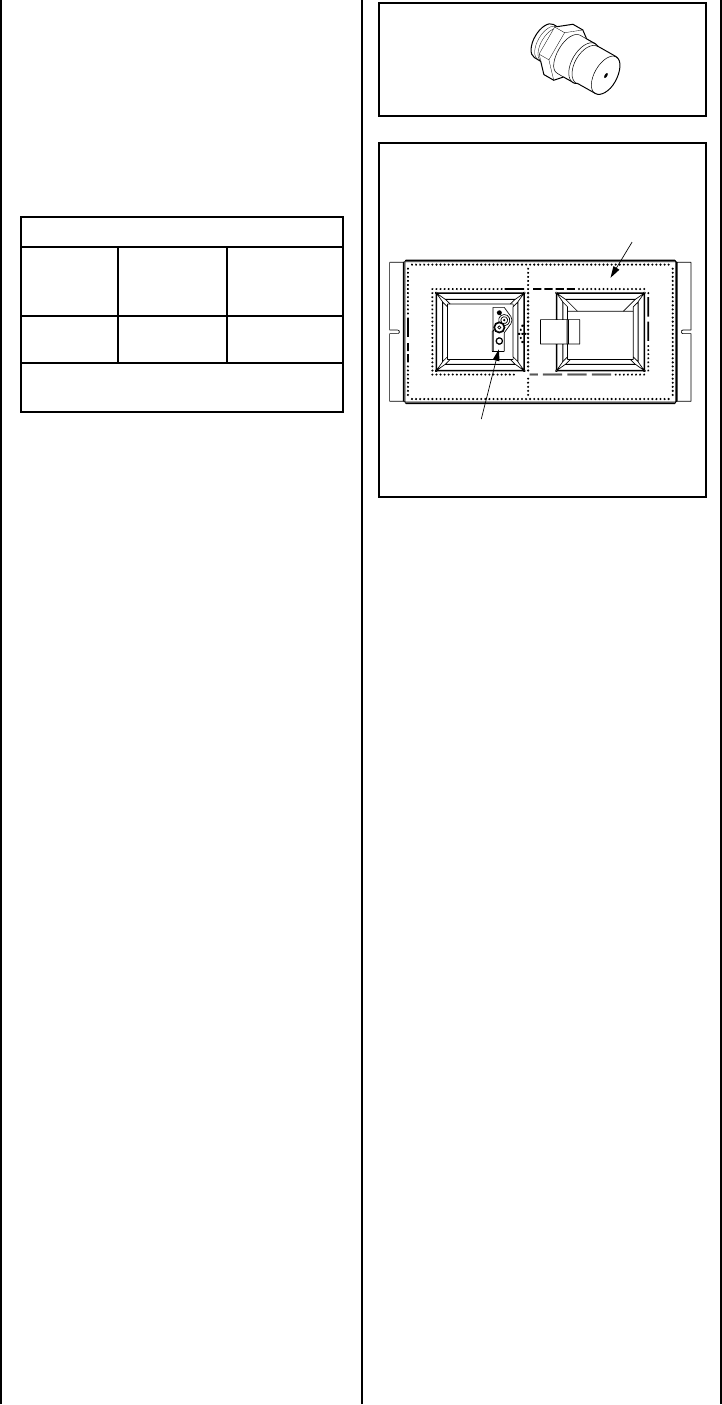

Figure 73

Step 9. Reassemble the remaining components

by reversing the procedures outlined in the

preceding steps.

Use pipe joint compound or Teflon tape on all

pipe fittings before installing (ensure propane

resistant compounds are used in propane ap-

plications, do not use pipe joint compounds

on flare fittings).

Step 10. Attach the conversion label provided

in the conversion kit to the rating plate on the

appliance.

Step 11. Turn on gas supply and test for gas

leaks.

ALWAYS TEST PRESSURE WITH THE VALVE

REGULATOR CONTROL AT THE HIGHEST

SETTING

B. Install the burner as shown in Figure 73.

Ensure that the arm of the venturi of the burner

is hooked onto the air shutter adjustment lever

(refer to Figure 67 on page 41).The primary air

opening can be adjusted by rotating the adjust-

ment lever from beneath the firebox floor. Refer

to Figure 65 on page 36 for the recommended

minimum primary air opening setting.

BURNER POSITIONING

PAN

BURNER

PILOT ASSEMBLY

Burner Orifice Sizes (all models)

Elevation

Feet (meters)

Natural

Gas

drill size (inches)

Propane

Gas

drill size (inches)

0-4500

(0-1372)

(0.125")

*

21L81 •

#41

(0.096")

*

21L82 •

Table 9

* Standard size installed at factory

• Part /Cat. Number