6

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

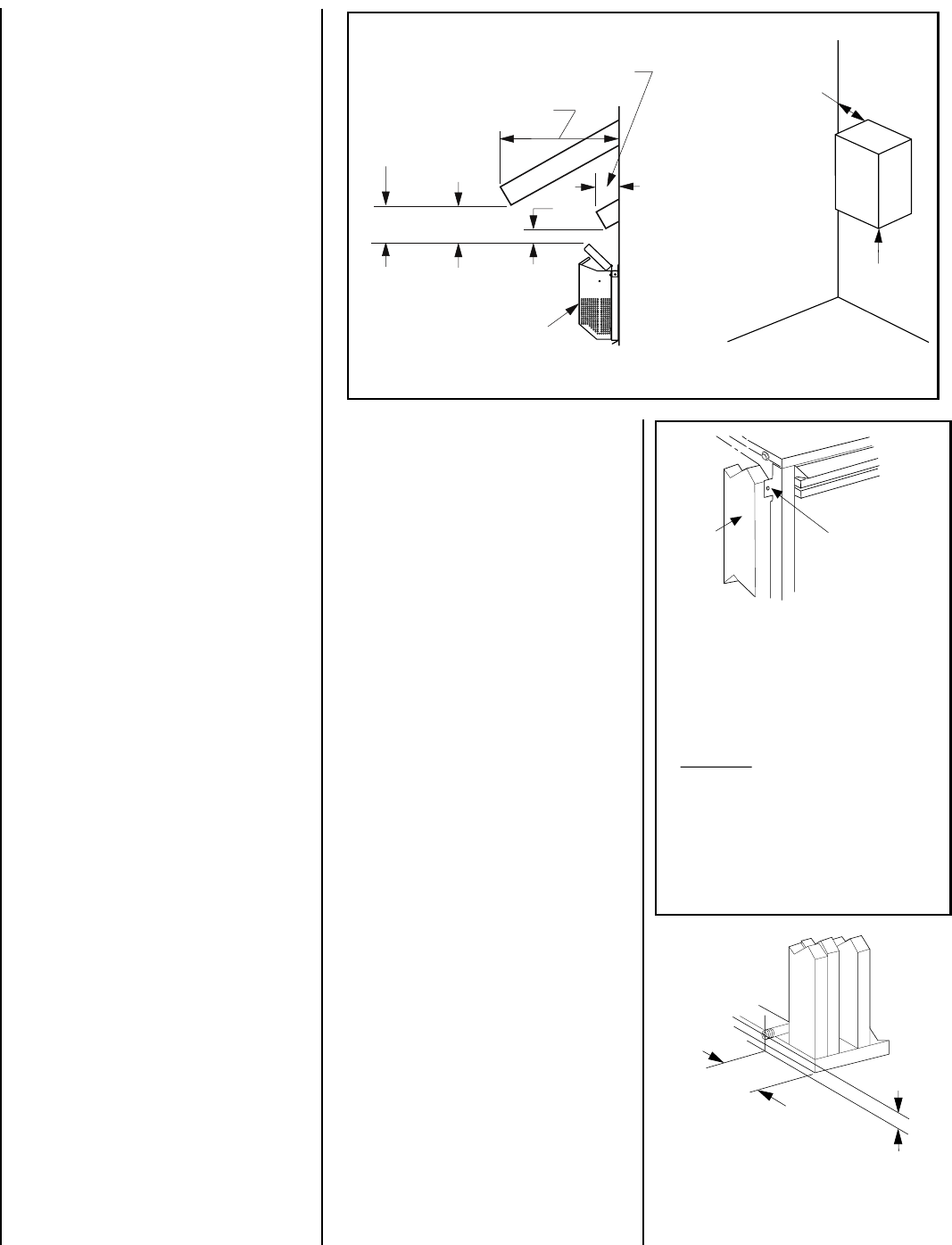

Unit Being Secured by Its Nailing

Flanges to the Framing

Figure 6

Right Side

Front Corner of

Fireplace Framing

6 ¹⁄₂"

(152 mm)

3"

(76 mm)

Note: The nailing flanges, combustible members

and screw heads located in areas directly adjacent

to the nailing flanges, are EXEMPT from the 1/2”

clearance to combustible requirements for the

firebox outer wrapper. Combustible framing may be

in

direct contact with the nailing flanges and may

be located closer than 1/2” from screw heads and

the firebox wrapper in areas adjacent to the nailing

flanges. Frame the opening to the exact dimensions

specified in the framing details of this manual.

Side

Framing

Unit Nailing Flange

(No clearance to

combustible

framing is required)

Left Side Front Corner of Fireplace Shown

(Right Side Requirements the Same)

Unit Being Secured By Its Nailing Flanges

To The Framing

Figure 7

Figure 5 -

Side Elevation View

3"

(76 mm)

12"

(305 mm)

Termination Kit

Combustible Projection

greater than inches in length

Combustible Projection

2-1/2 inches or less in length

18"

(457 mm)

Ventilated

Soffit

Unventilated

Soffit

Horizontal Vent Termination Clearances

2-1/2

Termination Kit

All horizontal terminations

may be located as close

as 6” (152mm) to any

(non-combustible and

combustible) exterior

sidewall. This distance

may be decreased to

2” (51mm) for non-

combustible exterior

sidewalls only, if the

SV4.5HT-2 termination

is used.

Step 2. ROUTING GAS LINE

Route a 1/2" (13 mm) gas line along the inside

of the right side framing as shown in

Figure 7

.

Gas lines must be routed, constructed and

made of materials that are in strict accordance

with local codes and regulations.

All appliances are factory-equipped with a flex-

ible gas line connector and 1/2 inch shutoff

valve. (See step 6 on page 23).

Step 1. FRAMING

Frame these appliances as illustrated in

Figure 9

on page 8,

unless the appliance is to be installed

in a corner

.

See

Figure 10 on page 8

for corner framing

installations. All framing details must allow for

a minimum clearance to combustible framing

members as shown in

Table 2 on page 4

.

If the appliance is to be elevated above floor

level, a solid continuous platform must be

constructed.

Headers may be in direct contact with the

appliance top spacers but must not be sup-

ported by them or notched to fit around them.

All construction above the appliance must be

self supporting, DO NOT use the appliance for

structural support.

The fireplace should be secured to the side

framing members using the unit's nailing flanges

- one top and bottom on each side of the

fireplace front. See

Figure 6.

Use 8d nails or

their equivalent.

TYPICAL INSTALLATION SEQUENCE

The typical sequence of installation follows,

however, each installation is unique resulting in

variations to those described.

See the page numbers references in the follow-

ing steps for detailed procedures.

Step 1. (page 6) Construct the appliance fram-

ing. Position the appliance within the framing

and secure with nailing brackets.

Step 2. (page 6) Route gas supply line to

appliance location.

Step 3. (page 10) Install the vent system and

exterior termination.

Step 4. (page 22) Field Wiring

a. Millivolt Appliances – The operating control

switch is factory installed.

b. Electronic Appliances – Connect 120 Vac

electrical power to the appliance receptacle.

Step 5. (page 23) Install blower kit (optional

equipment).

Step 6. (page 23) Make connection to gas

supply.

Step 7. (page 24) Install the logs, vermicu-

lite and glowing embers.

Step 8. (page 24) Checkout appliance operation.

Step 9. (page 24) Install glass door frame

assembly.

Step 10. (page 25) Adjust burner to ensure

proper flame appearance.

Step 11. (page 25) Install the hood.

DETAILED INSTALLATION STEPS

The appliance is shipped with all gas controls

and components installed and pre-wired. Re-

move the shipping carton, exposing the front

glass door. Remove the top panel. Remove the

cardboard from underneath the pressure re-

lief plates. Press in simultaneously the left and

right side of the bottom hinged panel, to release

it. Lower the bottom hinged panel. Open the

two latches (located under the firebox floor)

securing the glass door. Remove the door by

tilting it outward at the bottom and lifting it up.

Set the door aside protecting it from inadvert-

ent damage.

See Figure 52 on page 25.